Sewage treatment equipment and method for preventing adsorbent clogging and hardening

A sewage treatment method and adsorbent technology, which are applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of increasing treatment procedures and costs, wasting resources, and increasing swelling. and other problems, so as to avoid the increase of operating costs and investment costs, increase operating costs and investment costs, and resist water quality fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

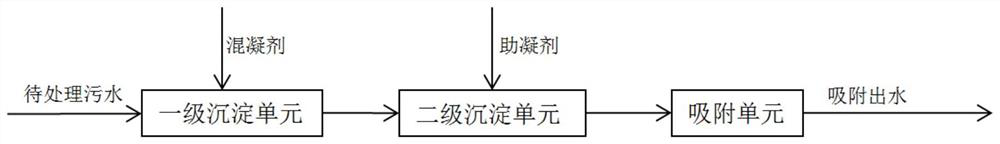

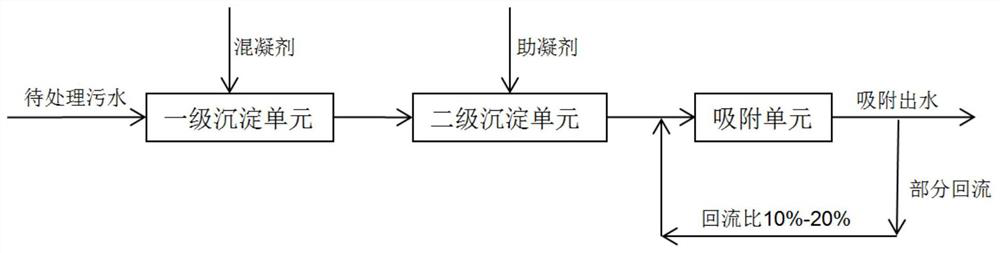

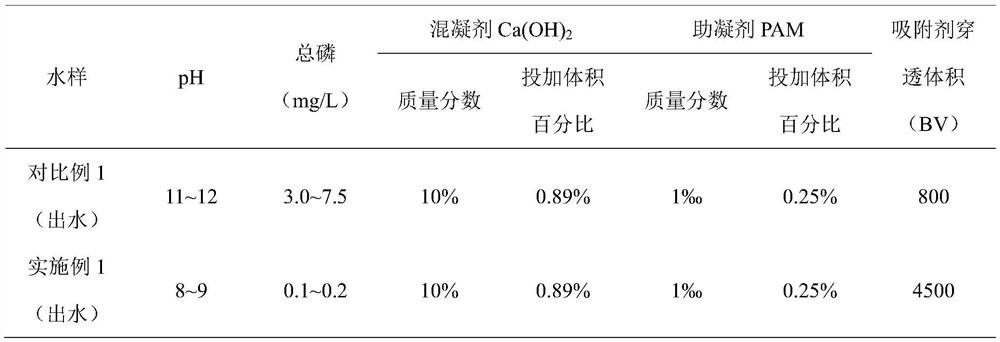

[0048] like figure 2 As shown, a kind of sewage treatment method that prevents adsorbent clogging and hardening of the present embodiment, treats the sewage that is the same as Comparative Example 1 and has the same treatment capacity, and its steps are:

[0049] (1) Make the sewage to be treated flow into the primary sedimentation tank, and add Ca(OH) with a mass percentage of 10% 2 , Ca(OH) 2 The dosage is 2.68m 3 / d (0.89% of sewage treatment capacity), stir evenly and carry out fast precipitation, react 10min;

[0050] (2) After the mixed reaction in step (1), the effluent flows into the secondary sedimentation unit (flocculation sedimentation tank), and polyacrylamide with a mass percentage of 1‰ is added to the flocculation sedimentation tank, and the dosage of polyacrylamide is 0.75m 3 / d (0.25%), stir evenly to carry out flocculation reaction for 30 minutes, and let stand for 90 minutes to slowly precipitate;

[0051] (3) The supernatant after the precipitation of...

Embodiment 2

[0064] like figure 2 As shown, a kind of sewage treatment method that prevents adsorbent clogging and hardening of the present embodiment, and comparative example 2 handles the sewage of the same type and the same treatment capacity and adopts the same adsorbent, and its treatment process is the same as embodiment 1, the difference is that :

[0065] The coagulant uses polyaluminum chloride (PAC) with a mass percentage of 20%, and the dosage is 0.3m 3 / d; the mass percent of coagulant PAM is 0.5‰, and the dosage is 0.6m 3 / d; after it was left to settle for 120min, the supernatant liquid entered the adsorption tower; 15% of the adsorbed water in the step (3) was returned to before the adsorption tower in the step (3) by the reflux pipeline.

[0066] When the adsorbent reaches a breakthrough when the water volume is about 400BV, it needs to be washed once with 1% hydrochloric acid by mass.

[0067] To traditional coagulation-precipitation-adsorption method (comparative exam...

Embodiment 3

[0077] like figure 2 As shown, a kind of sewage treatment method that prevents adsorbent clogging and hardening of the present embodiment, and comparative example 3 handles the sewage of the same type and the same treatment capacity and adopts the same adsorbent, and its treatment process is the same as embodiment 1, the difference is that :

[0078] The coagulant uses polyaluminum chloride with a mass percentage of 1%, and the dosage is 6m 3 / d; coagulant PAM mass percentage is 2‰, dosage is 0.3m 3 / d; after it was left to settle for 90min, the supernatant liquid entered the adsorption tower; 20% of the adsorption water in step (3) was returned to before the adsorption tower in step (3) by the reflux pipeline.

[0079] When the volume of water entering the adsorbent is about 1900BV, it reaches breakthrough, and it needs to be washed once with 1% hydrochloric acid by mass.

[0080] To traditional coagulation-precipitation-adsorption method (comparative example 3, such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com