Crystalline silicon solar cell

A technology of solar cells and crystalline silicon, applied in the field of solar cells, can solve the problems of reducing the utilization rate of incident light, affecting the conversion efficiency of cells, adversely affecting the conversion efficiency of cells, etc., and achieving the effects of improving injection efficiency, high conversion efficiency, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

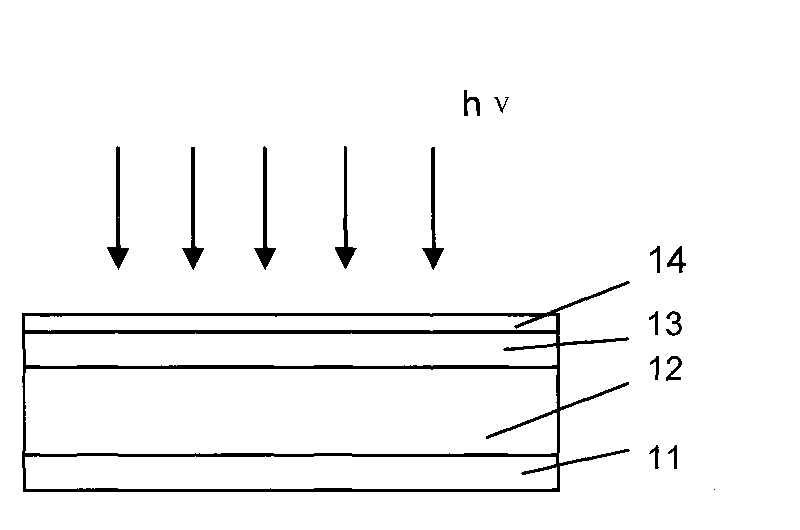

[0034] figure 2 This is a schematic diagram of the structure of the crystalline silicon solar cell in this embodiment.

[0035] Such as figure 2 As shown, crystalline silicon solar cells include:

[0036] p-type crystalline silicon substrate 12,

[0037] The n-type layer 13 on the substrate 12,

[0038] The cathode 14 on the n-type layer;

[0039] Wherein, the cathode 14 is a transparent conductive film, and its work function is less than or equal to 4.26 eV.

[0040] As a preferred technical solution, in this embodiment, the substrate 12 is composed of p-type crystalline silicon (single crystal silicon), and the thickness of the substrate 12 is in the range of 100-300 μm, preferably 220 μm in thickness, and the resistivity range is about It is 0.1-100 Ω·cm, and the resistivity is preferably 1.0 Ω·cm.

[0041] On the back light surface of the substrate 12, there is a metal aluminum electrode 11 made by a traditional process. The metal aluminum electrode 11 serves as the back electrode ...

Embodiment 2

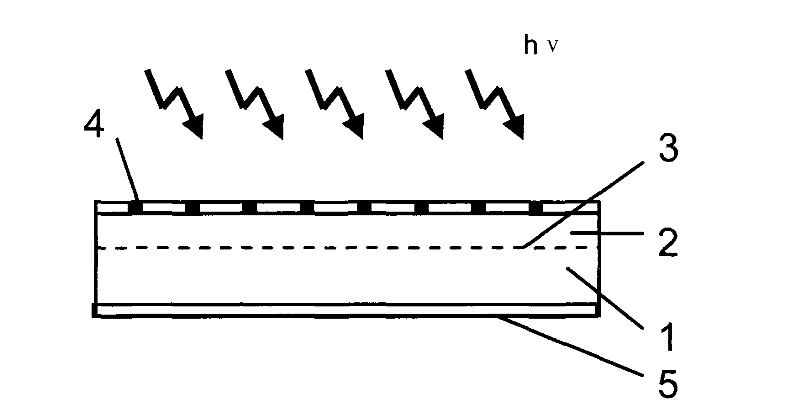

[0054] image 3 This is a schematic diagram of the structure of the crystalline silicon solar cell in this embodiment.

[0055] Such as image 3 As shown, crystalline silicon solar cells include:

[0056] p-type crystalline silicon substrate 22,

[0057] The n-type layer 23 on the substrate 22 is also a diffusion layer formed in a certain depth on the surface of the substrate 22,

[0058] The cathode 24 on the n-type layer has a metal back electrode 21 on the backlight surface of the substrate 22;

[0059] Wherein, the cathode 24 is a transparent conductive film, and its work function is less than or equal to 4.26 eV. Preferably, the transparent conductive film of the cathode 24 is LaB 6 , Deposited on the n-type layer by electron beam evaporation, LaB 6 The work function of the material is about 2.6~3.0eV, LaB 6 The thickness of the transparent conductive film ranges from 80 to 800 nm, and the thickness is preferably 250 nm.

[0060] The above is the same as the structure of the first ...

Embodiment 3

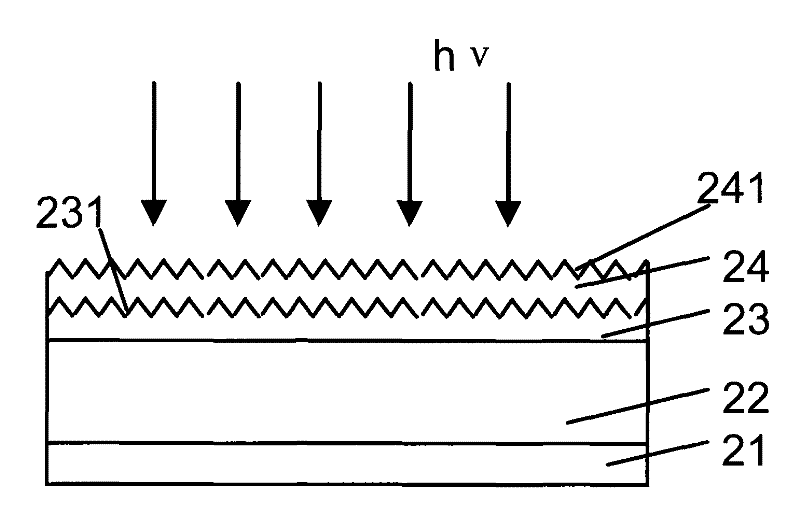

[0065] Figure 4 This is a schematic diagram of the structure of the crystalline silicon solar cell in this embodiment.

[0066] Such as Figure 4 As shown, crystalline silicon solar cells include:

[0067] p-type crystalline silicon substrate 32,

[0068] The n-type layer 33 on the substrate 32, the n-type layer 33 is doped thin film silicon,

[0069] The cathode 34 on the n-type layer;

[0070] Wherein, the cathode 34 is a transparent conductive film, and its work function is less than or equal to 4.26 eV. Preferably, the transparent conductive film of the cathode 34 is LaB6, which is deposited on the n-type layer by electron beam evaporation. The work function of the LaB6 material is about 2.6 to 3.0 eV. The thickness of the LaB6 transparent conductive film is in the range of 80 to 800 nm, and the preferred thickness is 250nm.

[0071] The difference between this embodiment and the previous embodiments is that an n-type doped thin film silicon layer is used instead of the n-type dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com