Sleeve structure easy for recognizing square hole size

A technology of hole size and sleeve, applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of lengthening the driving tool 92 hours, increasing the production cost, and selecting troubles, and achieves the effect of shortening the lead time and reducing the cost of labor hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

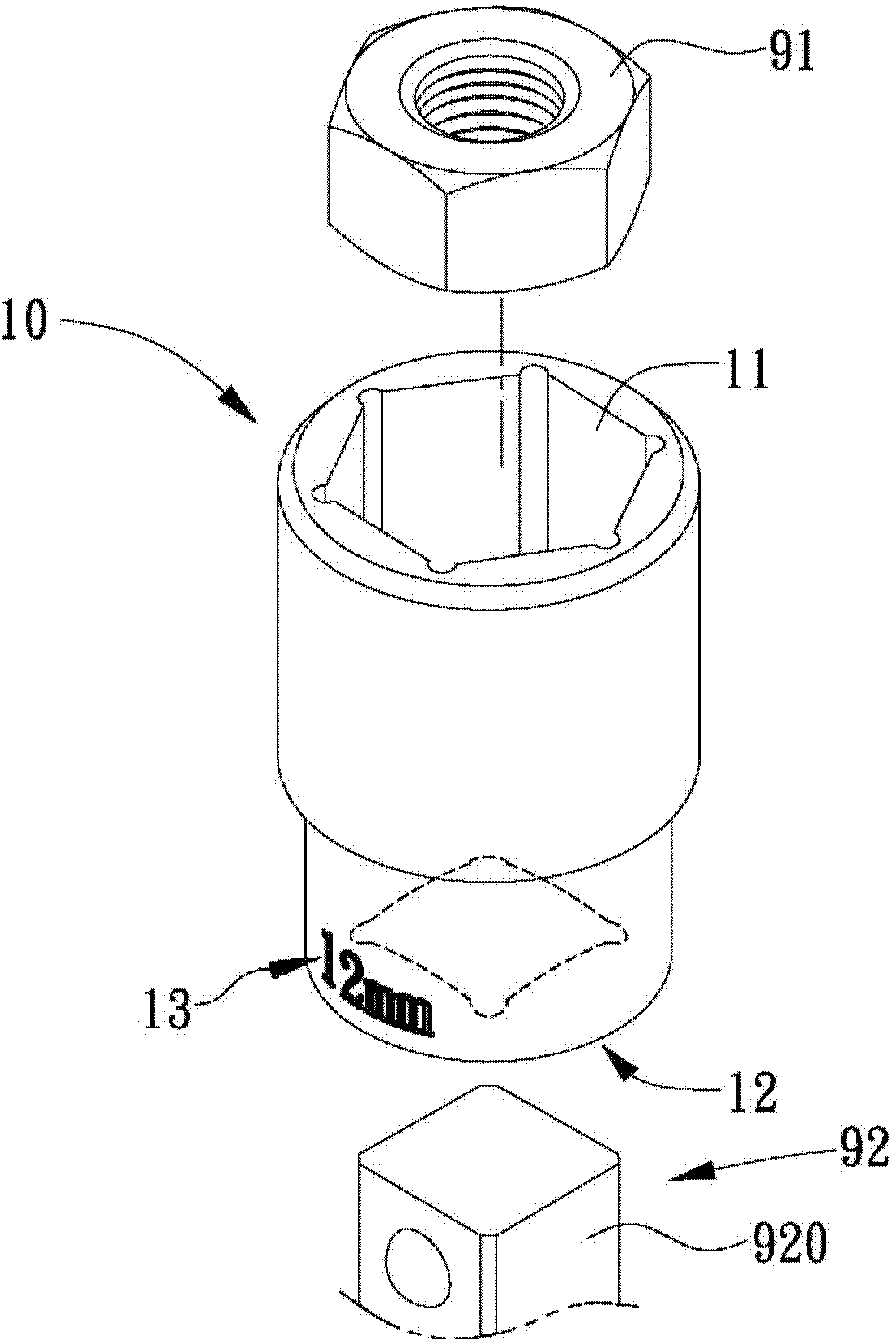

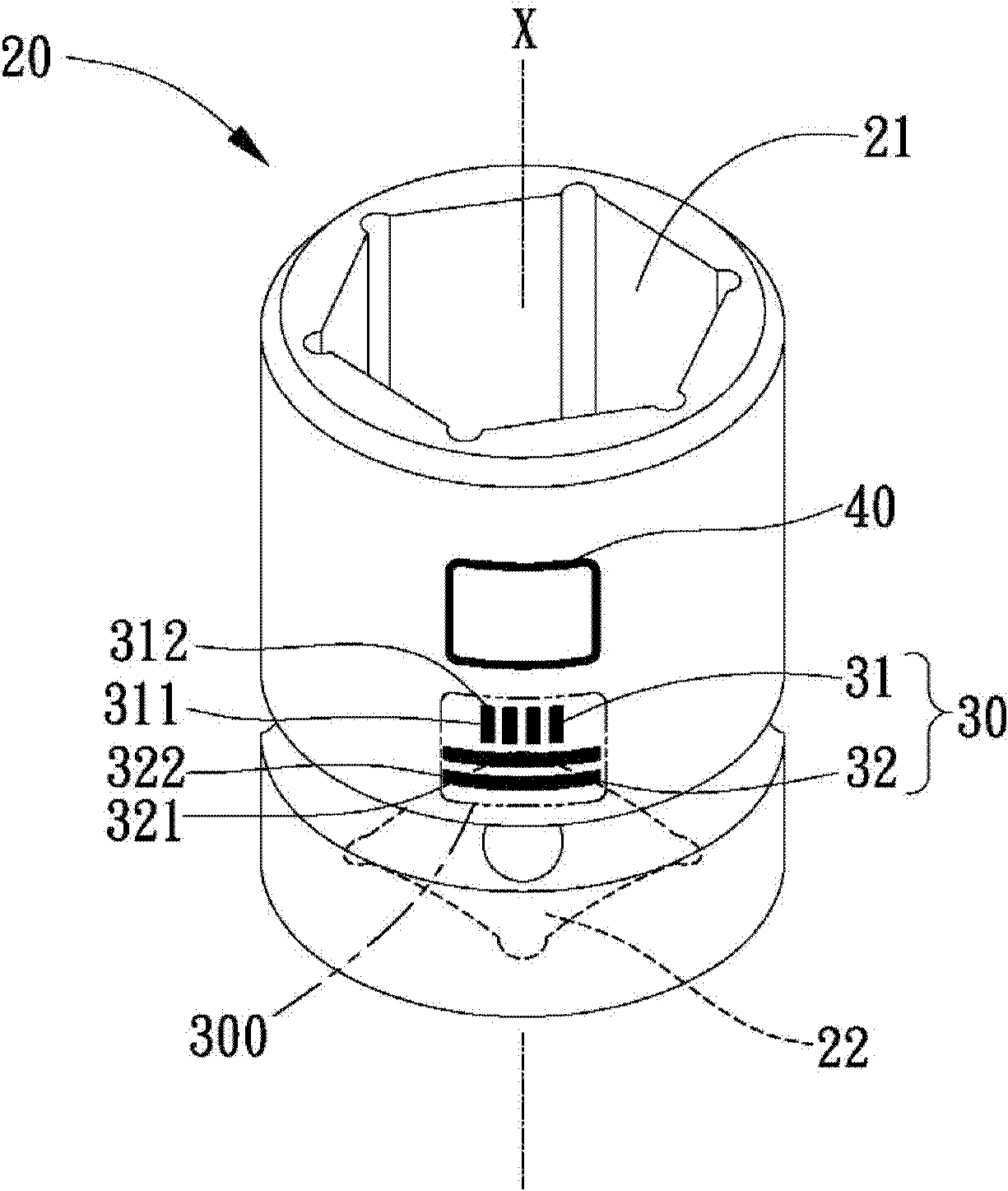

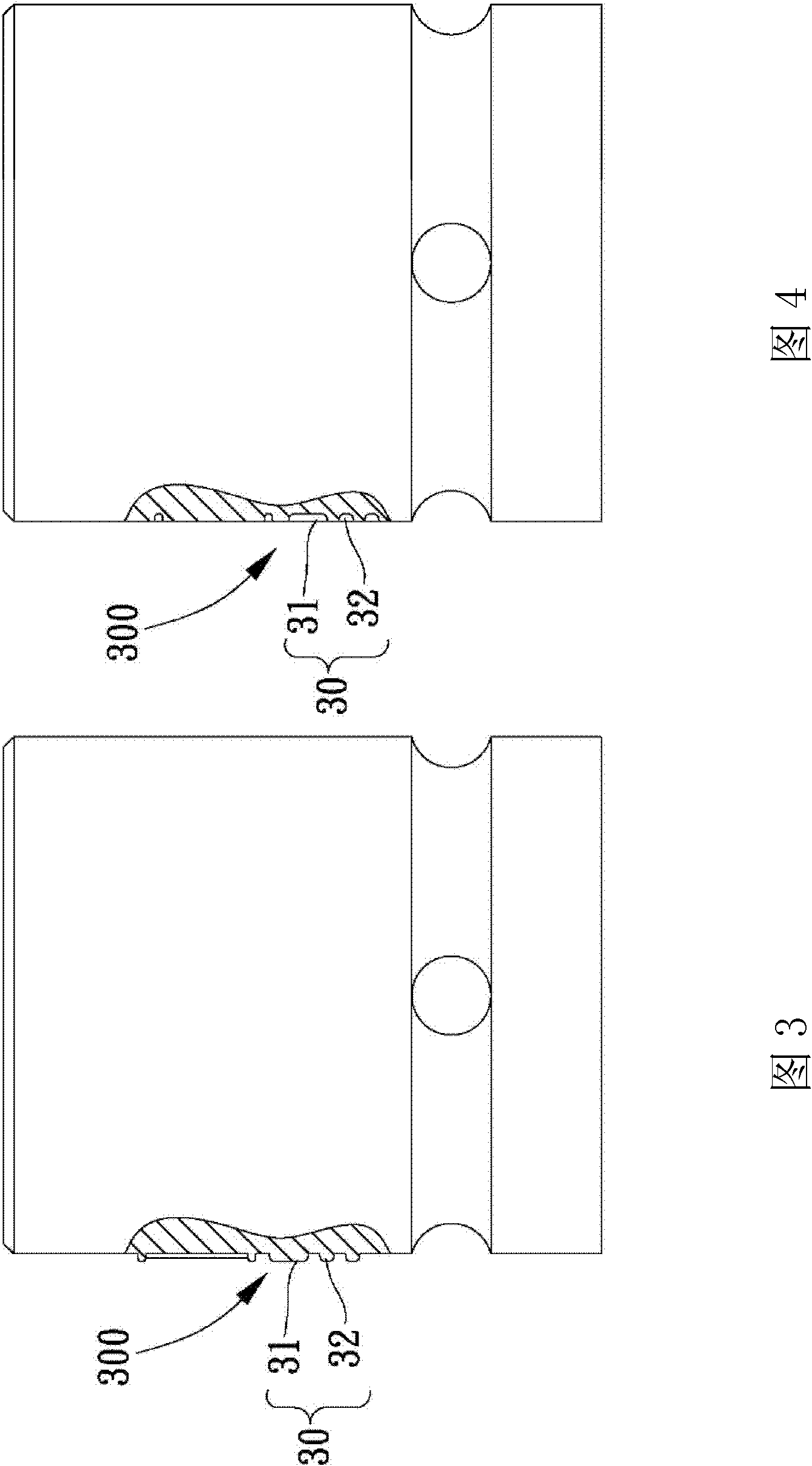

[0029] A preferred embodiment of the identification structure of the sleeve of the present invention is as follows Figures 2 to 6 As shown, the identification structure is formed on the outer peripheral edge of a sleeve 20. An actuating hole 21 in the shape of a polygonal opening is arranged on the inner edge of one end of the sleeve 20 along the direction of the central axis X to drive the workpiece of the opposite shape. The inner edge of the other end of the cylinder 20 is provided with a square hole 22 along the direction of the central axis X, which is used for connecting the square head of a driving tool such as an external connecting rod or a wrench, so as to facilitate the transmission of power from the driving tool to the sleeve. 20, so that the workpiece in the action hole 21 of the sleeve 20 can be effectively driven;

[0030] And the identification structure is set respectively for the size of the actuation hole 21 and the square hole 22; wherein, the identificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com