Recovery mechanism for dust and waste residues of stones

A recovery mechanism, dust technology, applied in the field of stone dust waste residue recovery mechanism, can solve the problem of not seeing the stone dust waste residue recovery mechanism, etc., to achieve the effect of avoiding a large number of flying, convenient use, and avoiding physical harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

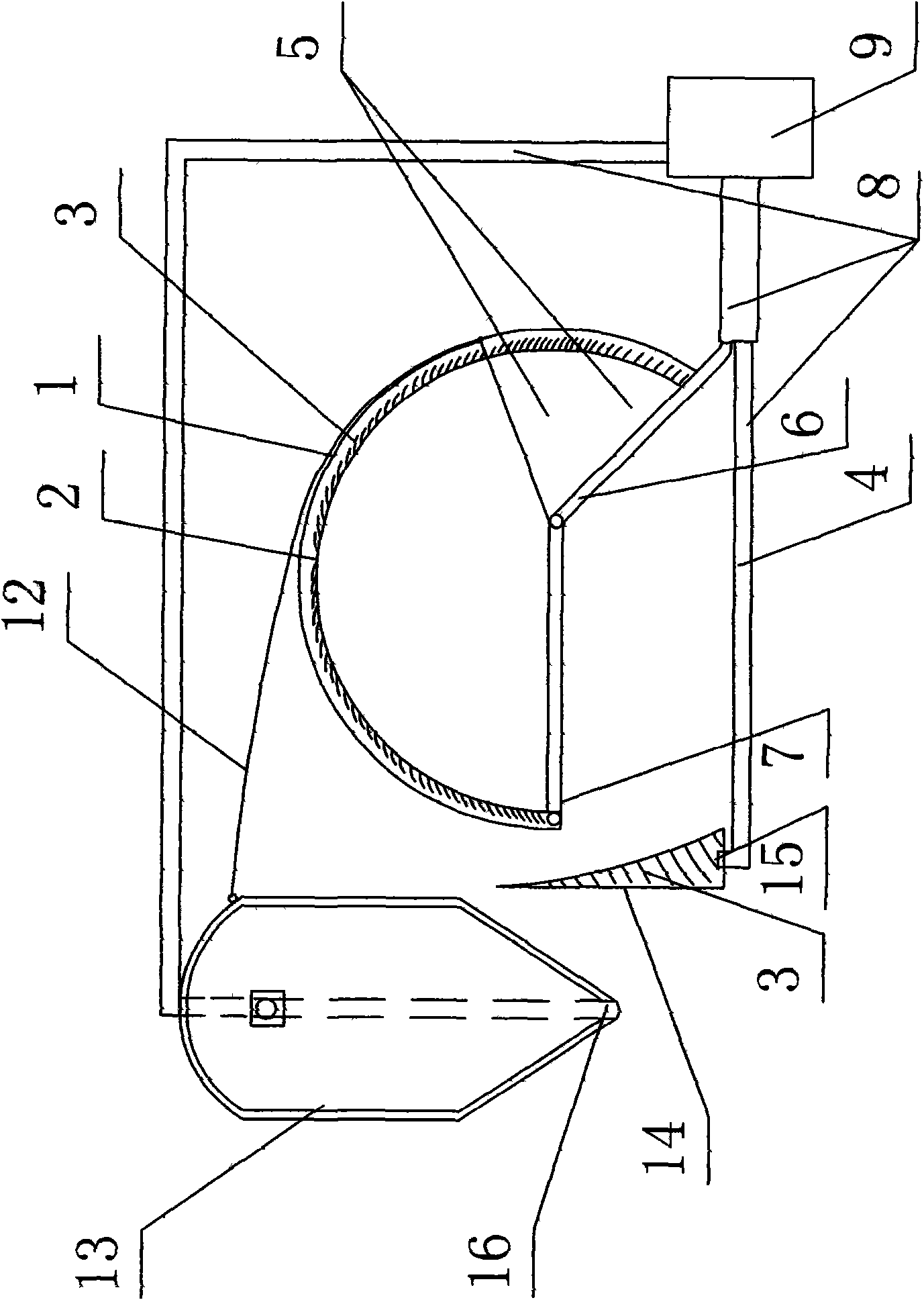

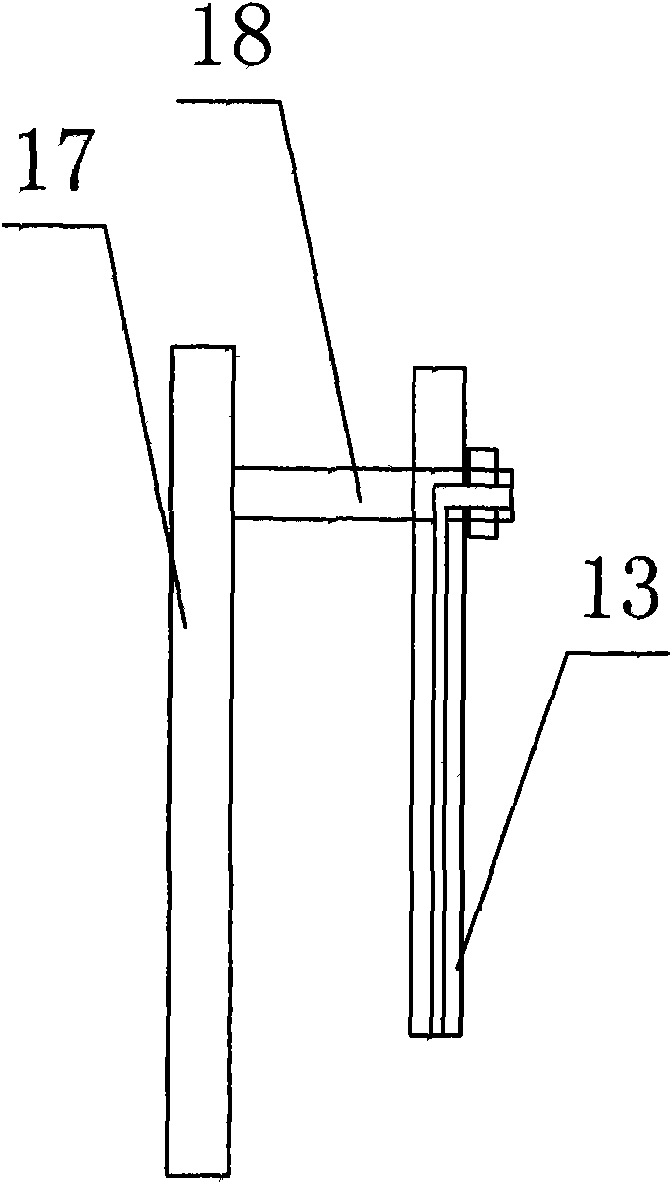

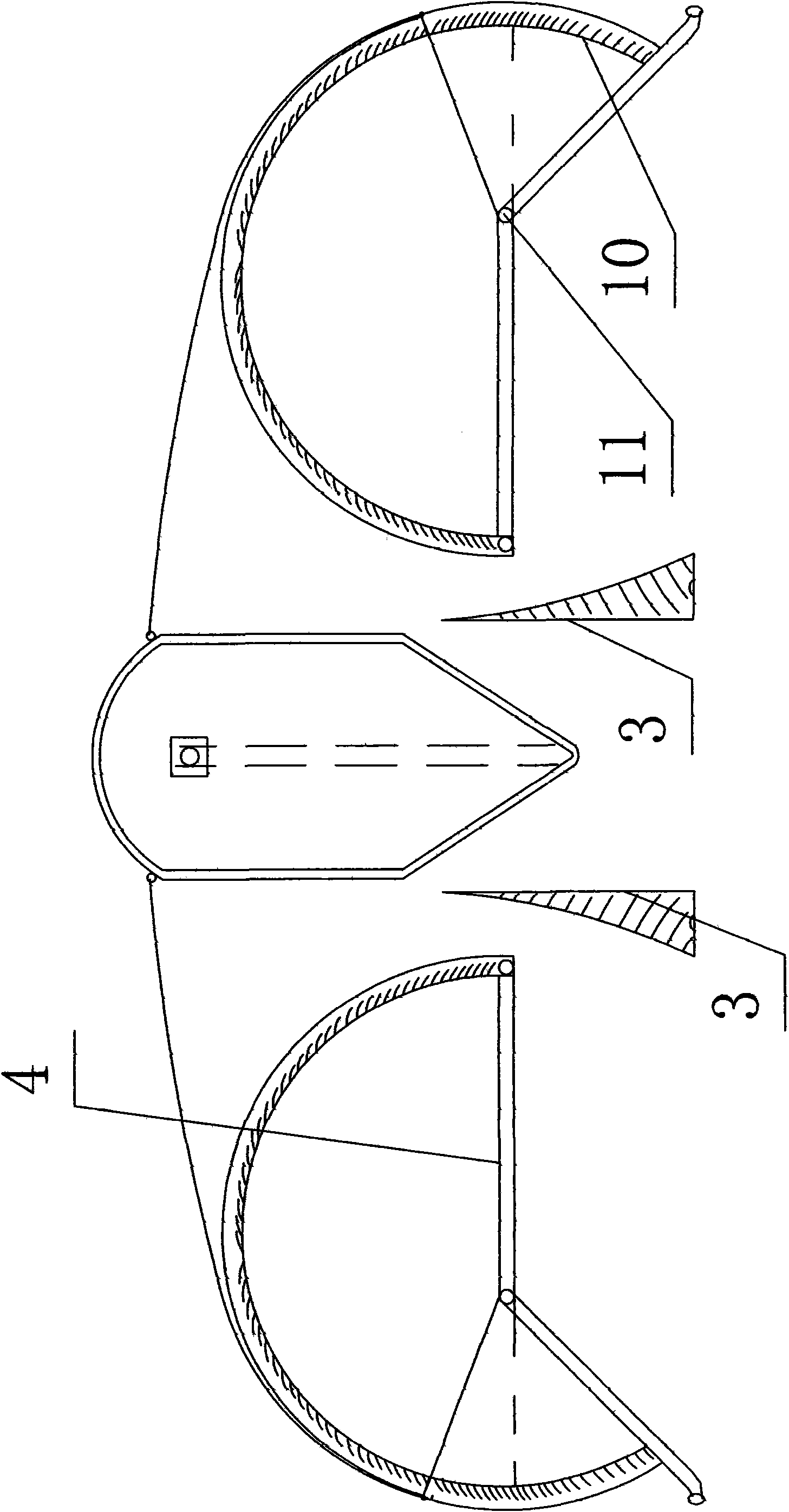

[0012] Such as figure 1 , figure 2 , image 3 , shown in Fig. 4, Fig. 5, stone material dust waste slag recovery mechanism of the present invention comprises frame, saw blade cover box 1, hollow dust-absorbing sheet and exhaust machine, and saw blade cover box 1 is fixed on the frame, The saw blade cover box 1 is covered on the saw blade to prevent the stone dust and waste slag sawn by the saw blade from flying. Its structural feature is that the saw blade cover box 1 is surrounded by the inner layer 2 and the outer layer of the box to form a semicircle with a cavity inside. Body, the inner surface of box inner layer 2 is provided with dust-proof sheet 3, is provided with horizontal suction pipe 4 on the other side of the bottom edge of saw blade cover box 1, is provided with at the bottom edge side of saw blade cover box 1 There is a movable plate box cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com