Straw hat glue and preparation method thereof

A technology of straw hats and raw rubber, applied in hat products, hats, adhesives, etc., can solve the problems of sizing personnel hazards, inhalation of toluene, etc., and achieve the effect of avoiding physical hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Embodiment 1-5 is used to illustrate the preparation method of raw gum in straw hat gum, specifically comprises the steps:

[0047] Step 1: Put the raw gum in a container with ethanol and stir;

[0048] Step 2: Add polyvinyl butyral evenly to the ethanol for raw gum while the ethanol for raw gum is in a stirring state, and control the adding time of polyvinyl butyral to 25-35 minutes;

[0049] Step 3: Continue to stir for 4-8 hours, and stop stirring when the raw gum is clear, transparent or slightly yellow;

[0050] Step 4: Seal the raw glue for 12-24 hours and set aside.

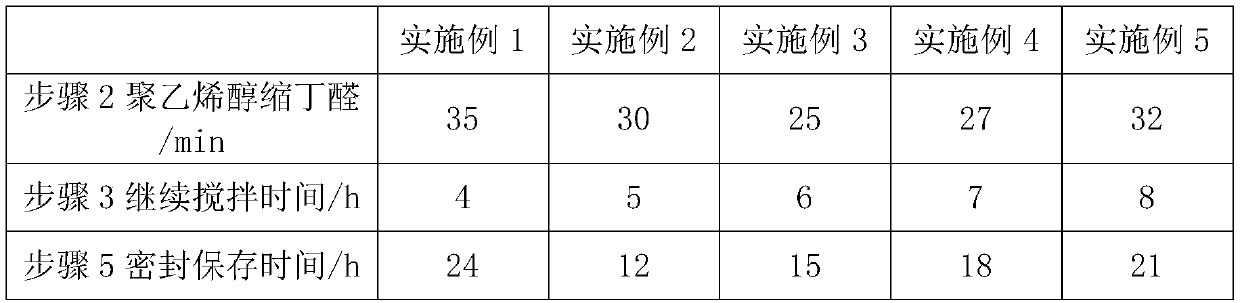

[0051] Table 1, the preparation method parameter table of original gum in the straw hat glue of embodiment 1-5

[0052]

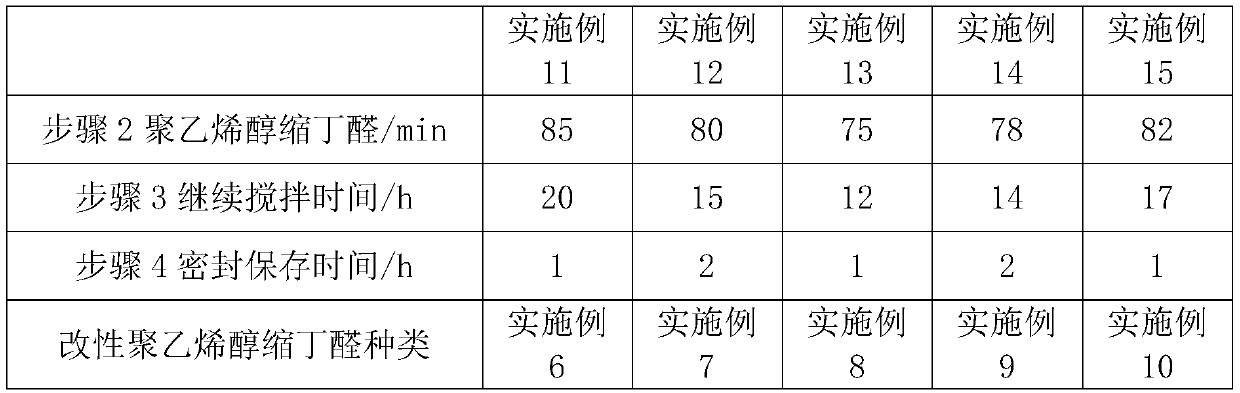

[0053] Examples 6-10 are used to illustrate the preparation method of modified polyvinyl butyral in straw hat glue. See Table 2 for the raw material components for preparing modified polyvinyl butyral in Examples 6-10.

[0054] Table 2, embodiment 6-10 prepare the raw mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com