Chemical dredging system for municipal drainage pipe network

A drainage pipe network, chemical technology, applied in waterway systems, cleaning sewer pipes, chemical instruments and methods, etc., can solve the problems of inconvenient road traffic, low efficiency, and worker safety threats.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

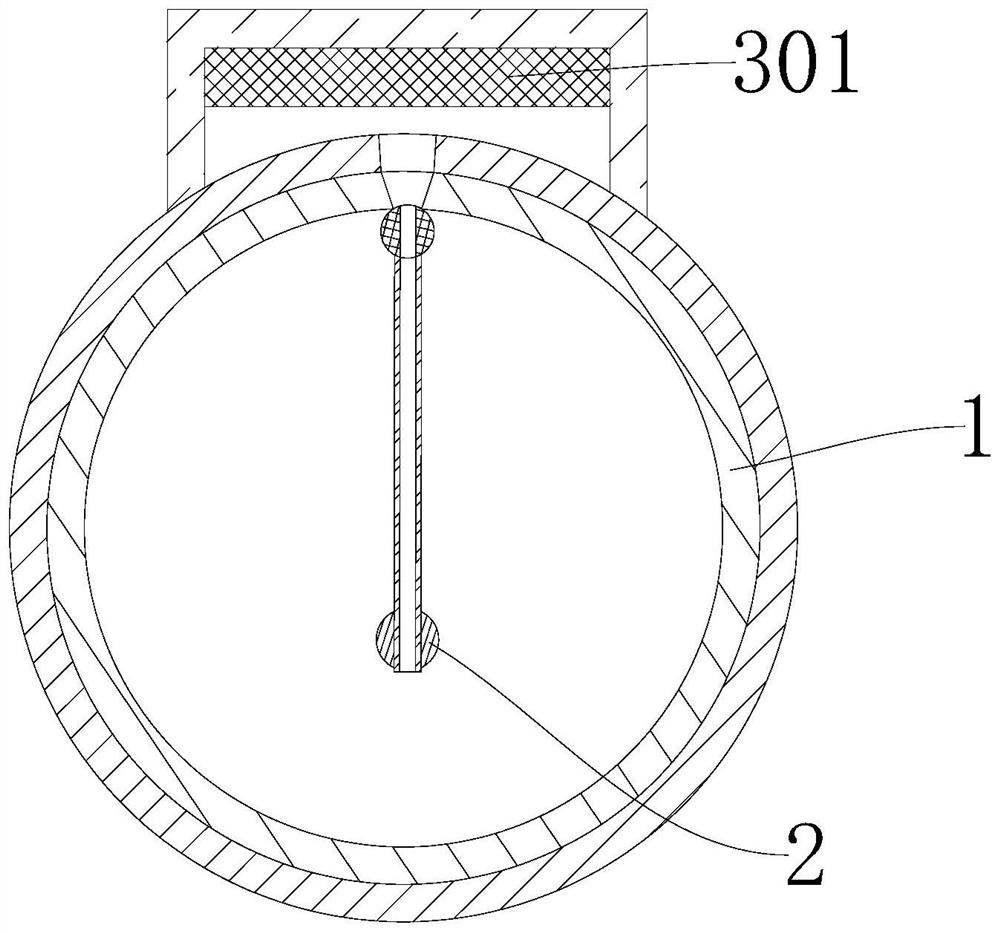

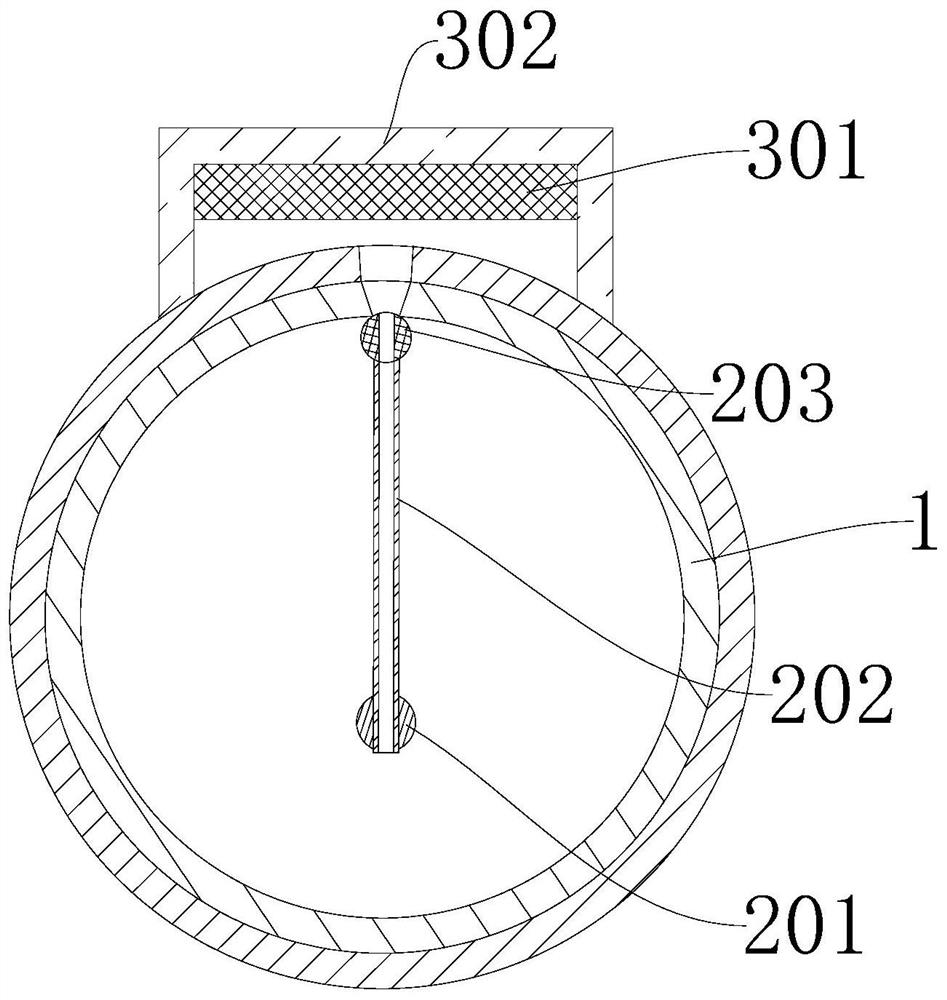

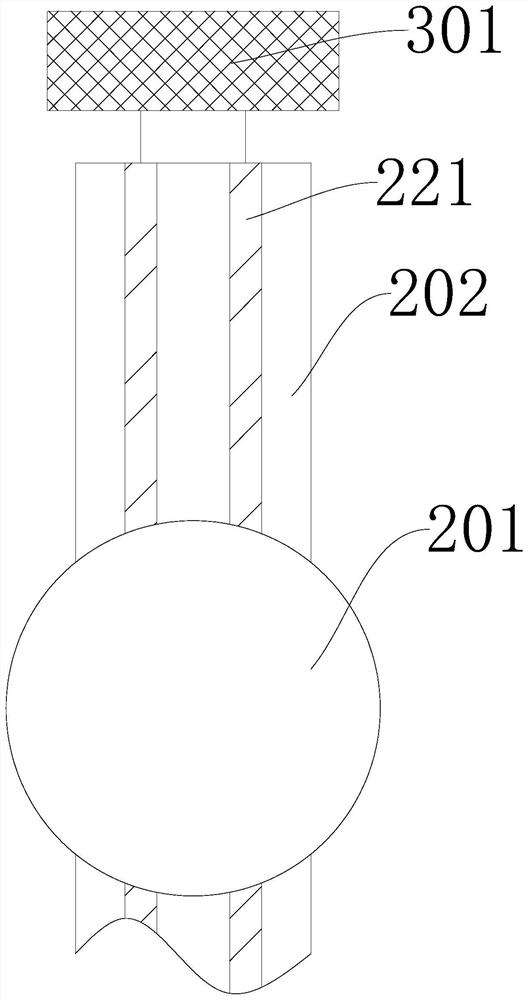

[0033] Such as figure 1 , 2 , 3, 4, and 5, the present embodiment provides a chemical dredging system for a municipal drainage pipe network, including a pipeline 1, a detection device and a sludge cleaning device, the detection device is connected to the pipeline 1, and the detection device includes a sludge height The measurement component 2 and the signal processor 301, the above-mentioned sludge height measurement component 2 is electrically connected with the above-mentioned signal processor 301, and the above-mentioned signal processor 301 is electrically connected with the above-mentioned sludge cleaning device.

[0034] In this embodiment, this embodiment provides a chemical dredging system for a municipal drainage pipe network, including a pipeline 1, a detection device and a sludge cleaning device, the detection device is connected to the pipeline 1, and the detection device includes a sludge height measurement component 2 And the signal processor 301, the silt heigh...

Embodiment 2

[0046] Such as figure 1 , 2 , 3, 4, and 5, on the basis of the embodiment, the above-mentioned sludge cleaning device includes a waterproof case 401, a control assembly 402, a drive assembly and a chemical dredging assembly, the above-mentioned control assembly 402, the above-mentioned drive assembly and the above-mentioned The chemical dredging components are all connected to the waterproof case 401, the control component 402 is electrically connected to the signal processor 301, and the control component 402 is electrically connected to the driving component and the chemical dredging component.

[0047] In this embodiment, the above-mentioned sludge cleaning device includes a waterproof case 401, a control component 402, a drive component, and a chemical dredging component. The control component 402 can be a single-chip microcomputer, etc., and the control component 402 also includes communication modules such as WIFI, Bluetooth, and 5G; the above The control assembly 402, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com