Multifunctional slot wedge molding die cutting machine

A die-cutting machine, multi-functional technology, applied in the direction of grinding machine parts, grinding machines, grinding drive devices, etc., can solve the problems of unfavorable enterprise processing and production, reduce work efficiency, occupy a large manpower, etc., to achieve reasonable structural design, High processing efficiency and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

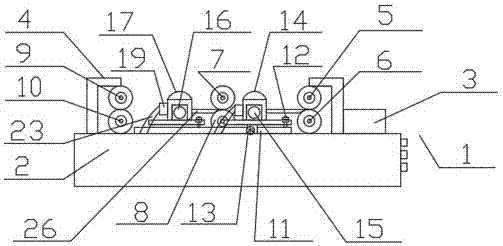

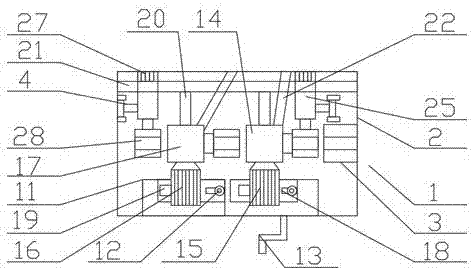

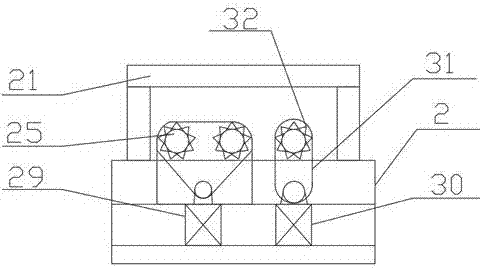

[0019] Such as Figure 1 to Figure 4 As shown, a multifunctional slot wedge forming die-cutting machine includes a body 1, the body 1 includes a base 2, a clamping device, a first motor 15 and a second motor 16, and a base 2 is arranged below the body 1 The right side of the upper surface of the base 2 is provided with a clamping device 3; the left side of the clamping device 3 is provided with a second grinding roller 6; the top of the second grinding roller 6 is provided with a first grinding roller 5 ; and the ends of the first grinding roller 5 and the second grinding roller 6 are connected with a roller shaft 25; The transition section 26 provided between the grinding roller 5 and the second grinding roller 6 is connected to the first sleeve 14; the upper surface of the base 2 is provided with a support member 11; and the surface of the support member 11 is provided with a slide rail 18; and the inside of the slide rail 18 is provided with an adjustment rod 12; and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com