Rod group structure of tent rods and mosquito net rods

A tent pole and mosquito net technology is applied to the pole group structure field of tent poles or mosquito net poles. The effect of increased speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

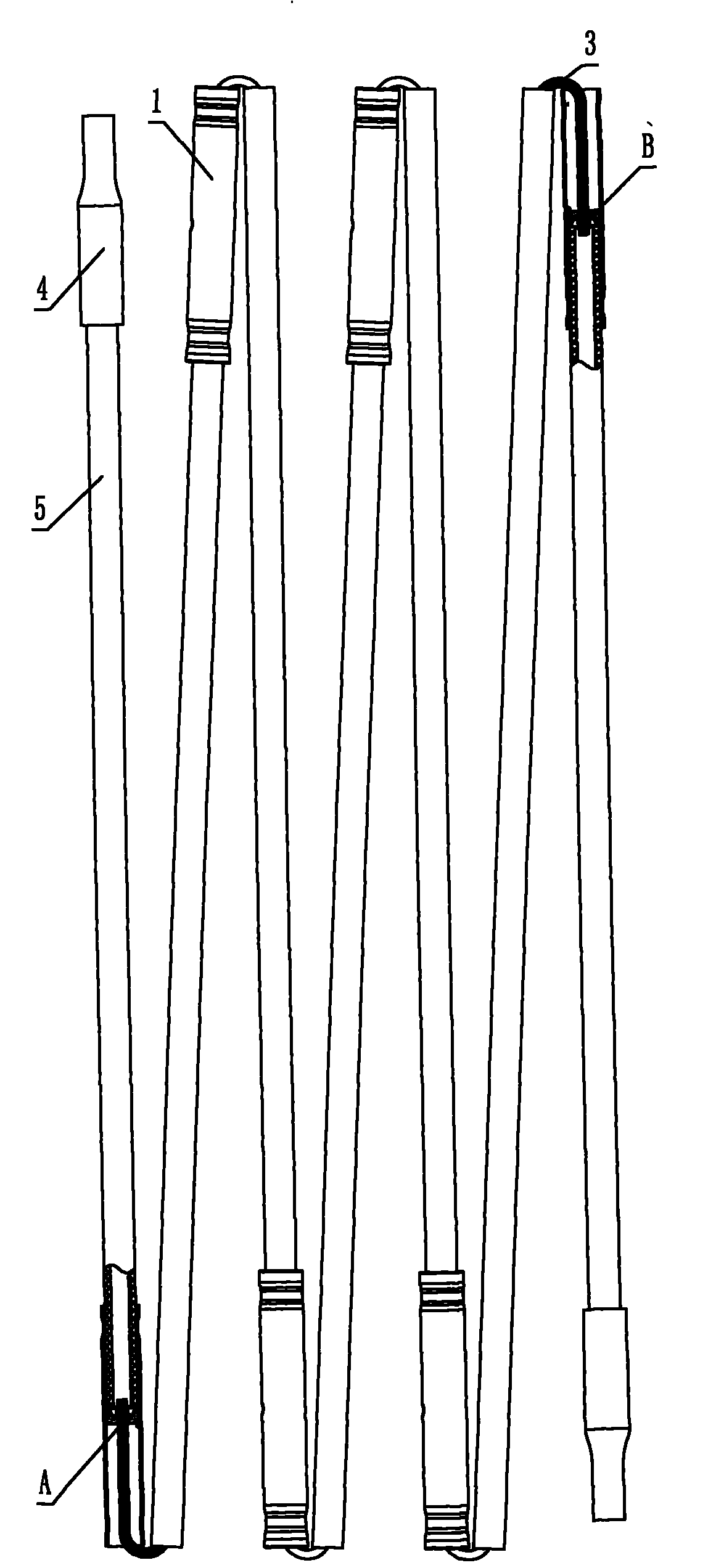

[0024] Depend on Figure 1-11 Represented is an embodiment of the present invention, a kind of tent pole mosquito net pole group structure, mainly comprises connecting sleeve 1, elastic cord fixing structure, tail end sleeve 4, tent pole 5, is equipped with connection between tent pole 5 Sleeve pipe 1, and the tent pole 5 ends of tail end sleeve pipe 4 and tent pole mosquito net pole group two ends are fixedly plugged in, and elastic cord fixing structure is housed in the connection sleeve pipe 1 of tent pole mosquito net pole group two ends.

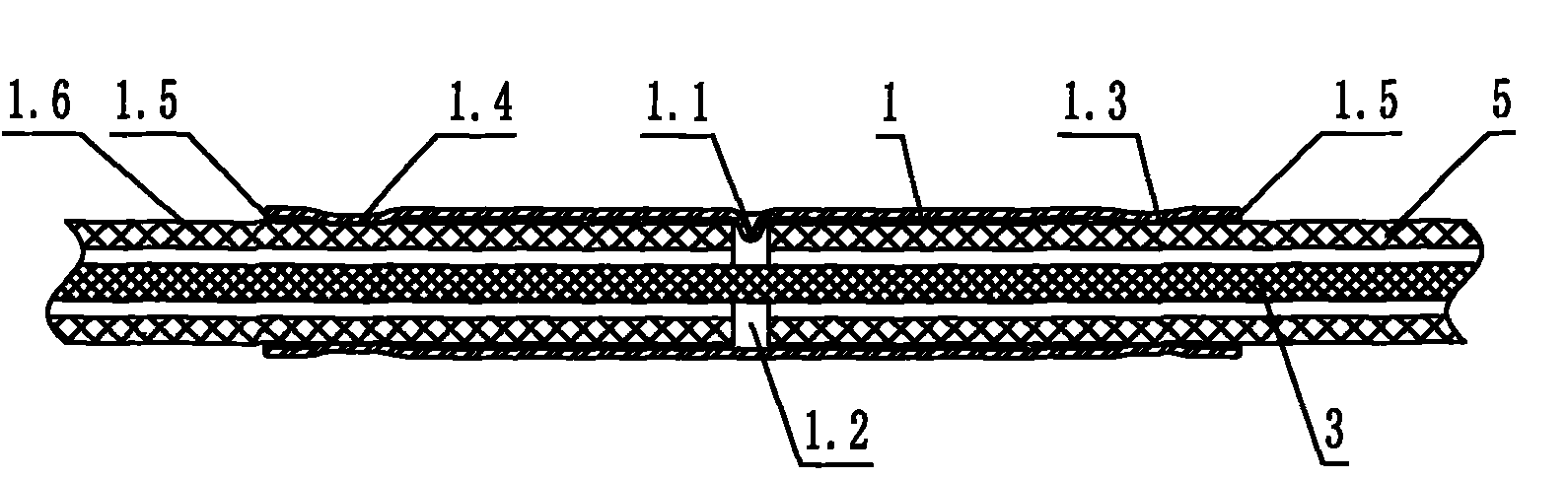

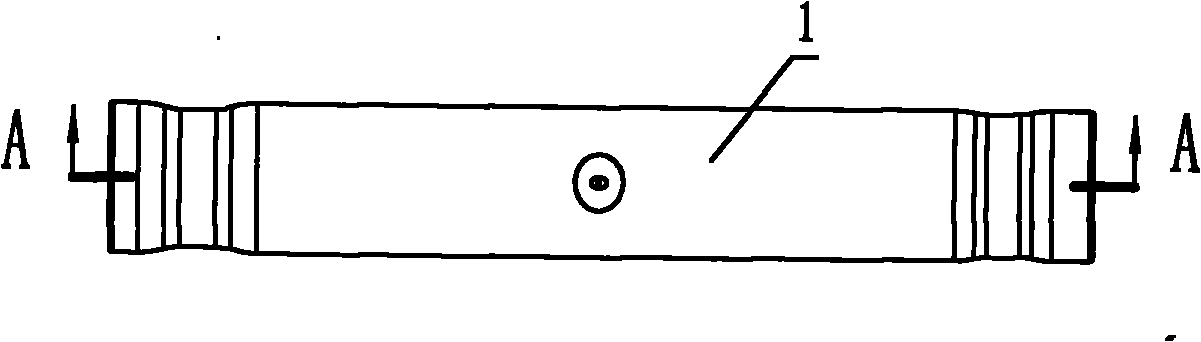

[0025] like Figure 3-Figure 6 As shown, the connecting sleeve 1 is stamped with a raised point 1.1 in the middle of its inner hole, which divides the inner hole of the connecting sleeve 1 into two, forming two sleeve inner holes 1.2, and two sleeve inner holes 1.2 It can be plugged with two tent poles 5 respectively, and its main points are: the diameter of the socket 1.2 in the sleeve pipe is slightly larger than the tent pole 5 diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com