Method for diagnosing interturn short circuit of rotor winding

A rotor winding and turn-to-turn short-circuit technology, which is applied in the field of motor rotor winding fault diagnosis, can solve problems such as increased power loss, high sensitivity, and low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

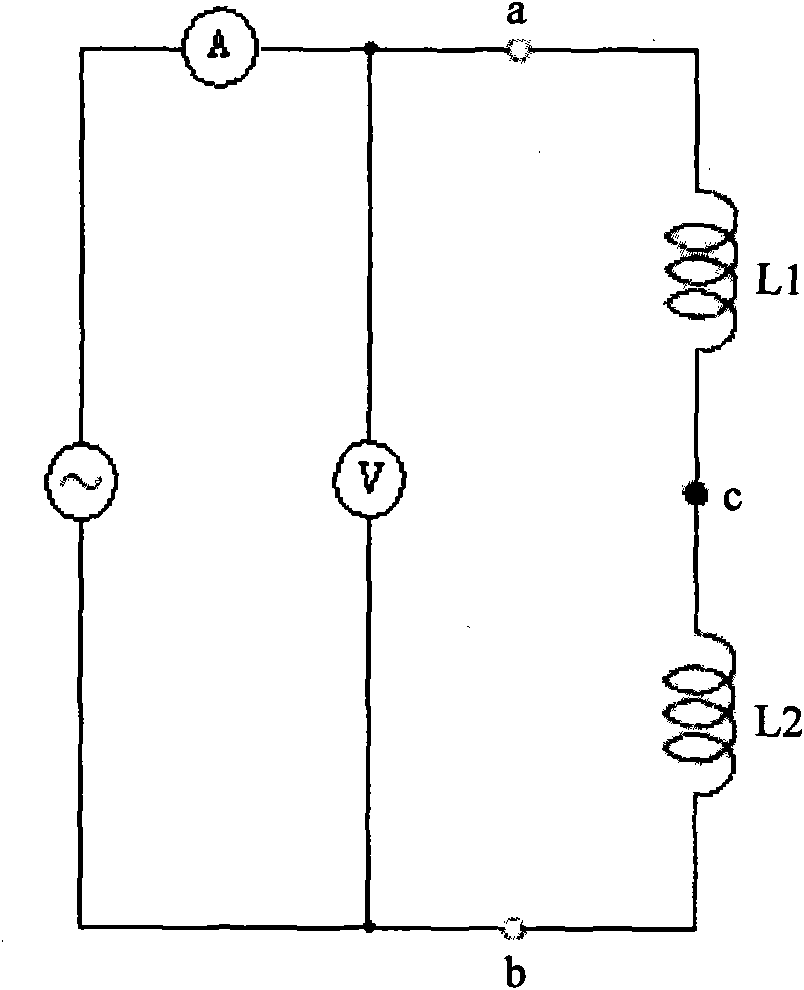

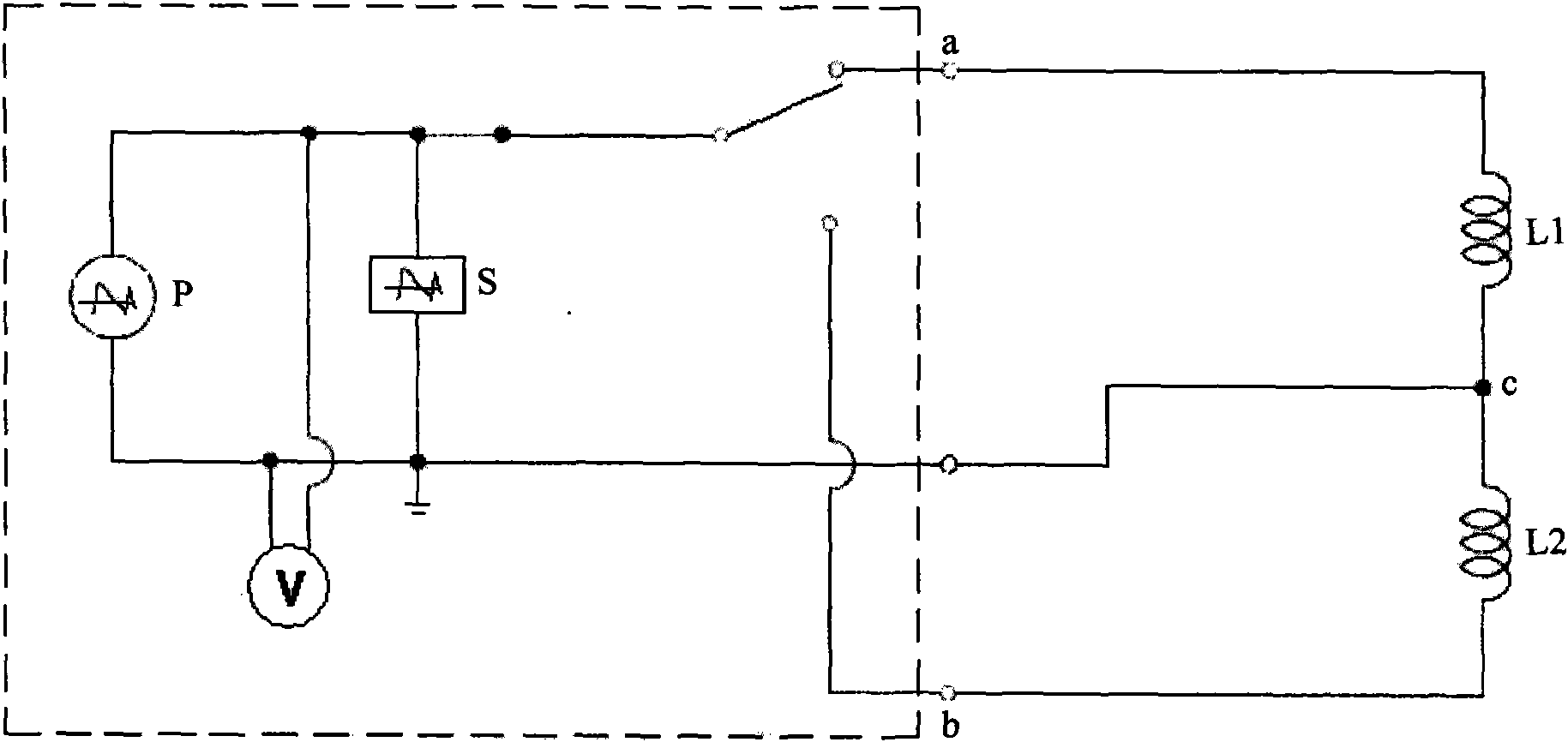

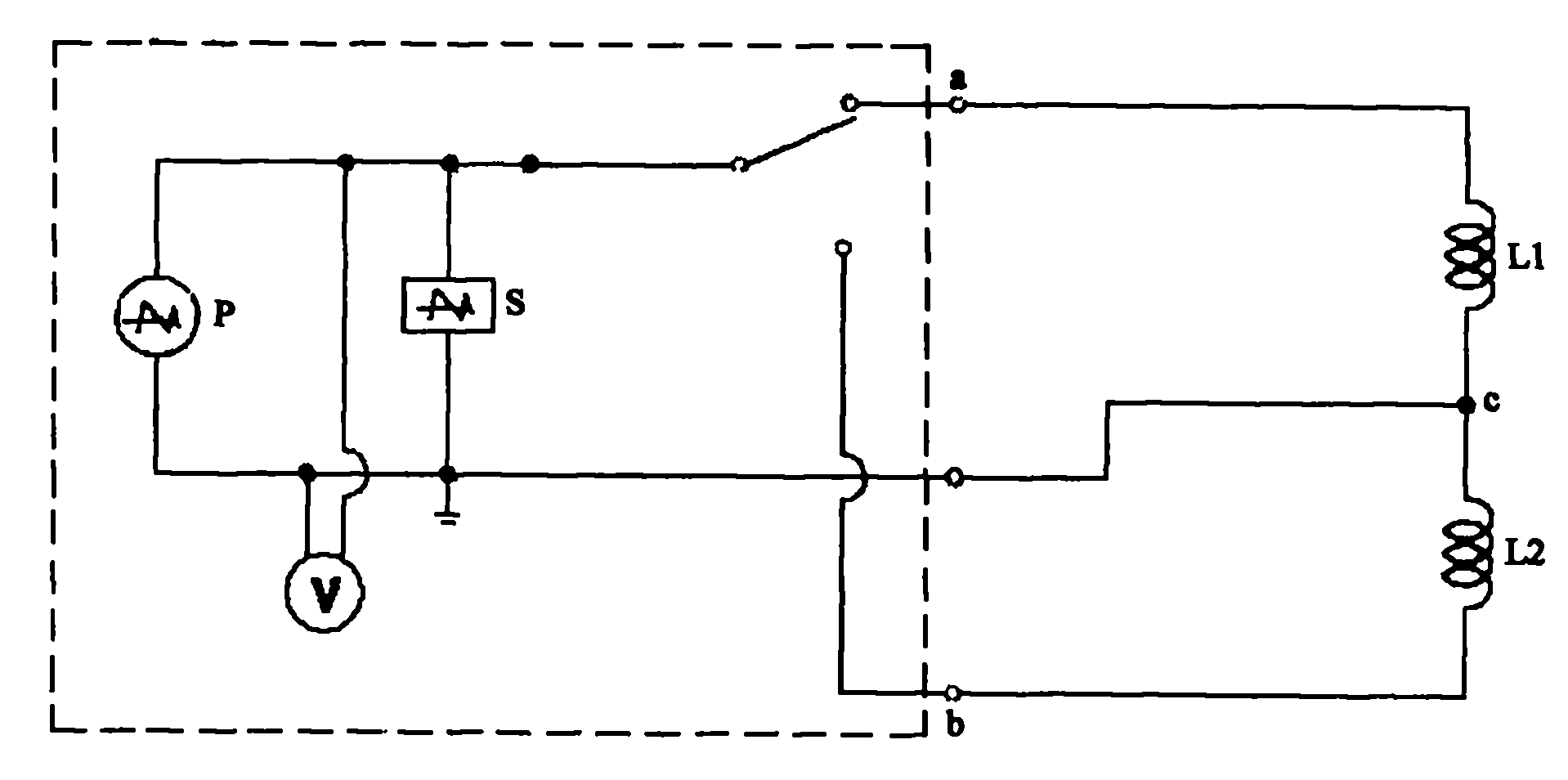

[0018] Embodiment one, such as figure 1 As shown, the AC impedance method in this method mainly applies a current excitation source between the positive lead end a and the negative lead end b of the generator rotor winding. The current requirement is greater than 1A, and the rotor winding (rotor positive coil L1 and rotor negative coil L2) the voltage at both ends, calculate the voltage and divide it by the current value to obtain the impedance value of the rotor winding, compare the calculated value with the previous value (or original value), if the relative error is less than 4%, it is considered that there is no stable turn short circuit fault. If the relative error is greater than 4%, it is considered that there is a stable turn-to-turn short circuit fault between the turns of the rotor, which needs to be dealt with. like figure 2 As shown, use the voltage oscillation generator P to apply a higher voltage oscillation wave to the positive and negative windings L1, L2 or...

Embodiment 2

[0019] Embodiment 2, for the rotor winding of the non-polar connection line, a higher voltage oscillating wave can be applied to the entire winding, and the amplitude of the oscillating wave voltage is 2 to 4 times the rated voltage of the rotor winding (depending on the rotor overvoltage level). The frequency of the oscillation wave is between 200 and 50,000 Hz. The positive electrode can be pressurized first, and then the negative electrode can be pressurized in reverse, for 3 to 5 consecutive times. The response waveforms are compared and analyzed. If the two waveforms are basically the same, or are consistent with the last waveform or the factory waveform, it is considered that there is no short-circuit fault, and the inter-turn insulation of the rotor winding is good. If there is a difference of more than 10% from the previous waveform peak value and phase, it is considered that there is a short circuit between the turns of the rotor winding.

[0020] The current public t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com