Moving contact device of moulded case circuit breaker

A technology of molded case circuit breakers and moving contacts, which is applied in the direction of circuit breaker contacts and circuit breaker parts, etc., can solve the problems of complicated process, inconvenient installation, and affecting the stability of the mechanism, and achieve simple process, convenient installation, and structural stability. reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

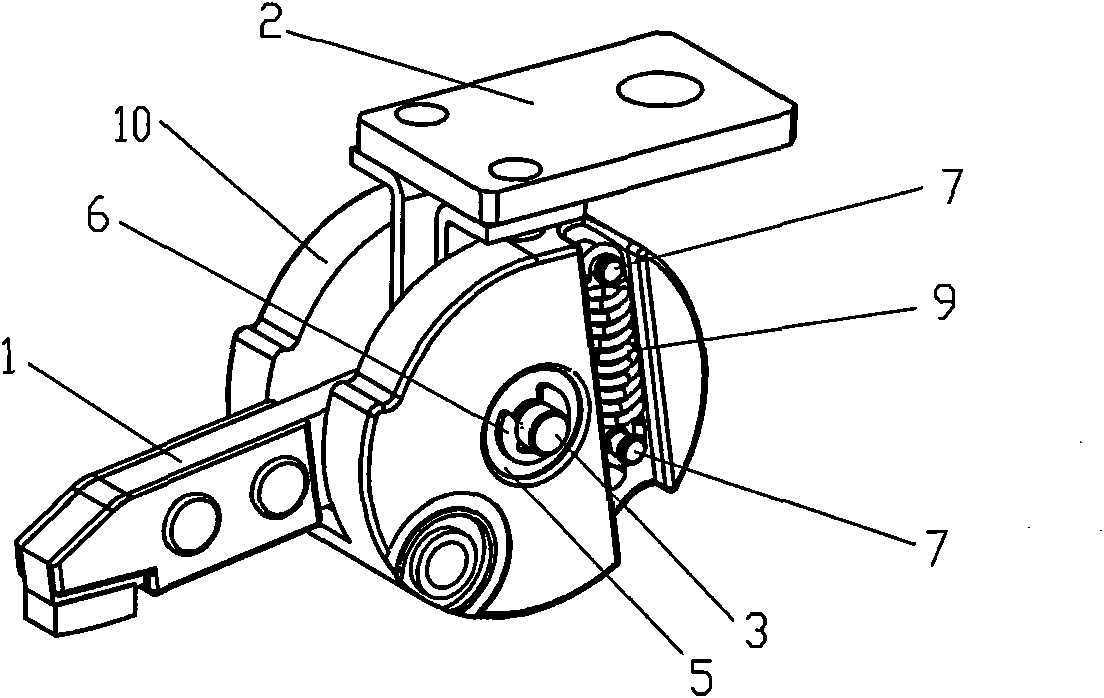

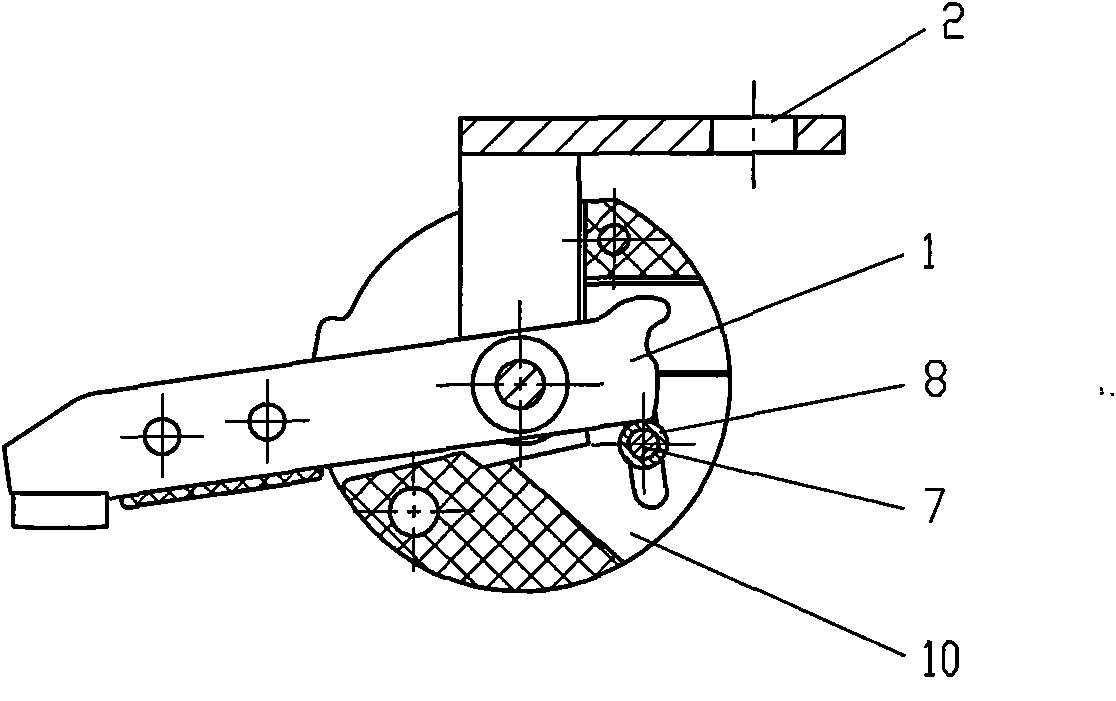

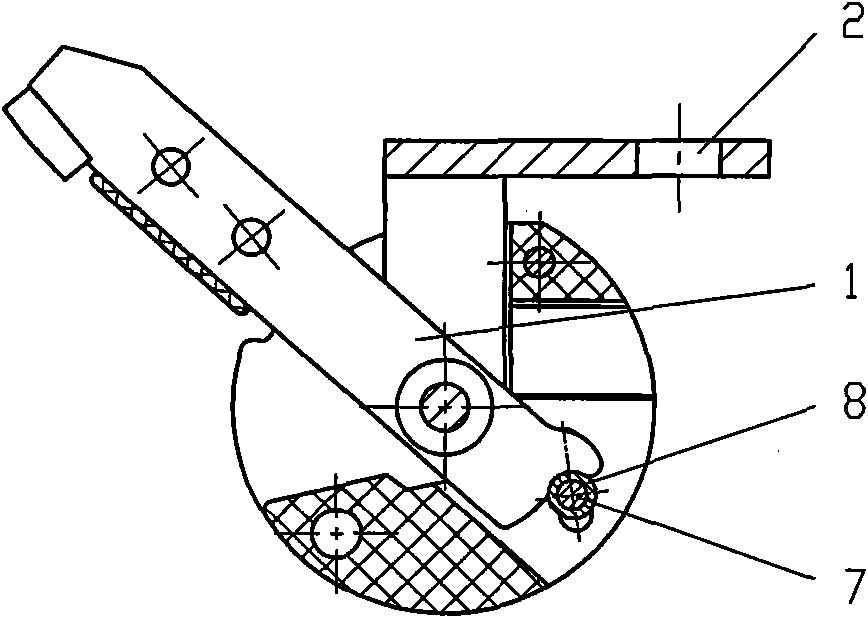

[0018] As shown in the figure, the moving contact device of the low-voltage molded case circuit breaker of the present invention consists of a moving contact 1, a bracket 2, a fixed pin 3, a disc spring 4, a compression sleeve 5, an open retaining ring 6, a pin shaft 7, The shaft sleeve 8, the tension spring 9 and the rotating shaft 10 are combined and installed, wherein the rotating shaft 10 is a thick and short cylinder with a circular shaft hole in the center, and the middle part of the cylinder along the axial direction has a fan-shaped groove. The tail of the holding moving contact 1 is inserted into the fan-shaped groove, the fixed pin 3 penetrates through one end of the central axis hole of the rotating shaft 10, passes through the pin of the bracket 2, the tail of the moving contact 1, and then passes out the other end of the central axis hole of the rotating shaft 10 Assemble and connect the rotating shaft 10, the bracket 2, and the moving contact 1. The two ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com