Improved solar component frame structure

A solar module and frame technology, which is applied in the field of solar energy applications, can solve the problems of difficult to control the uniformity of sealing, difficult to guarantee sealing performance, and decreased electrical insulation, and achieves a simple structure, good sealing shock absorption, and improved sealing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

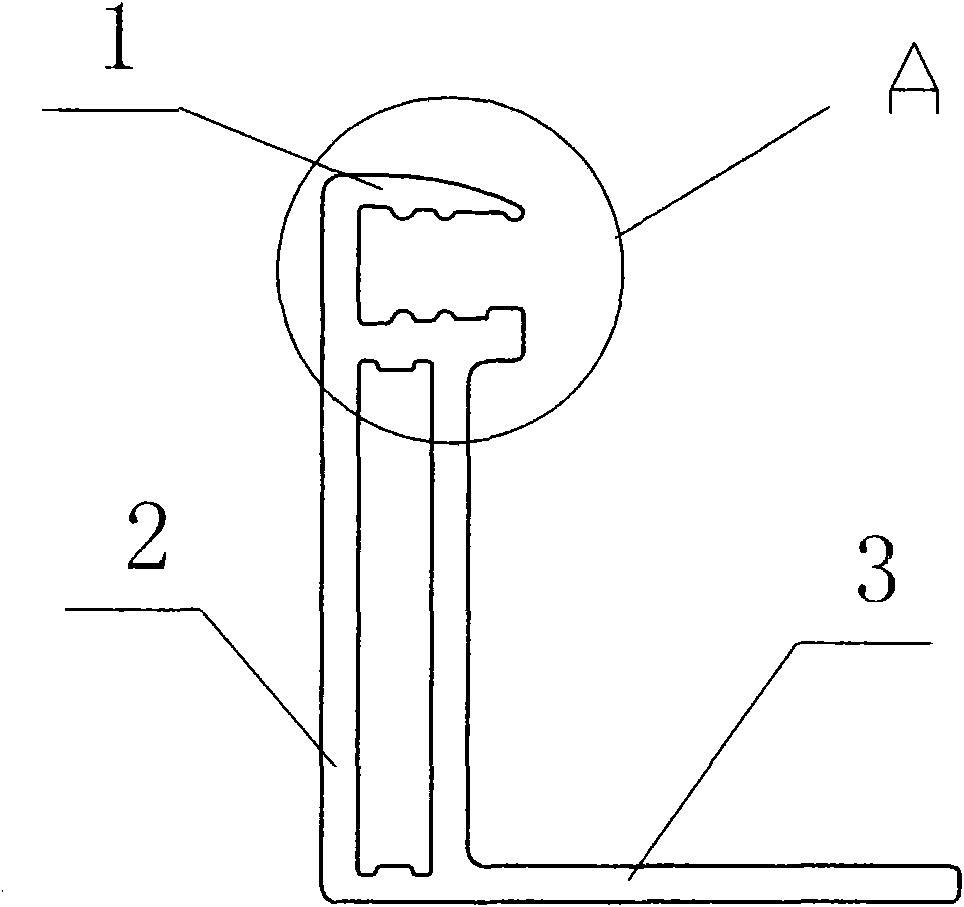

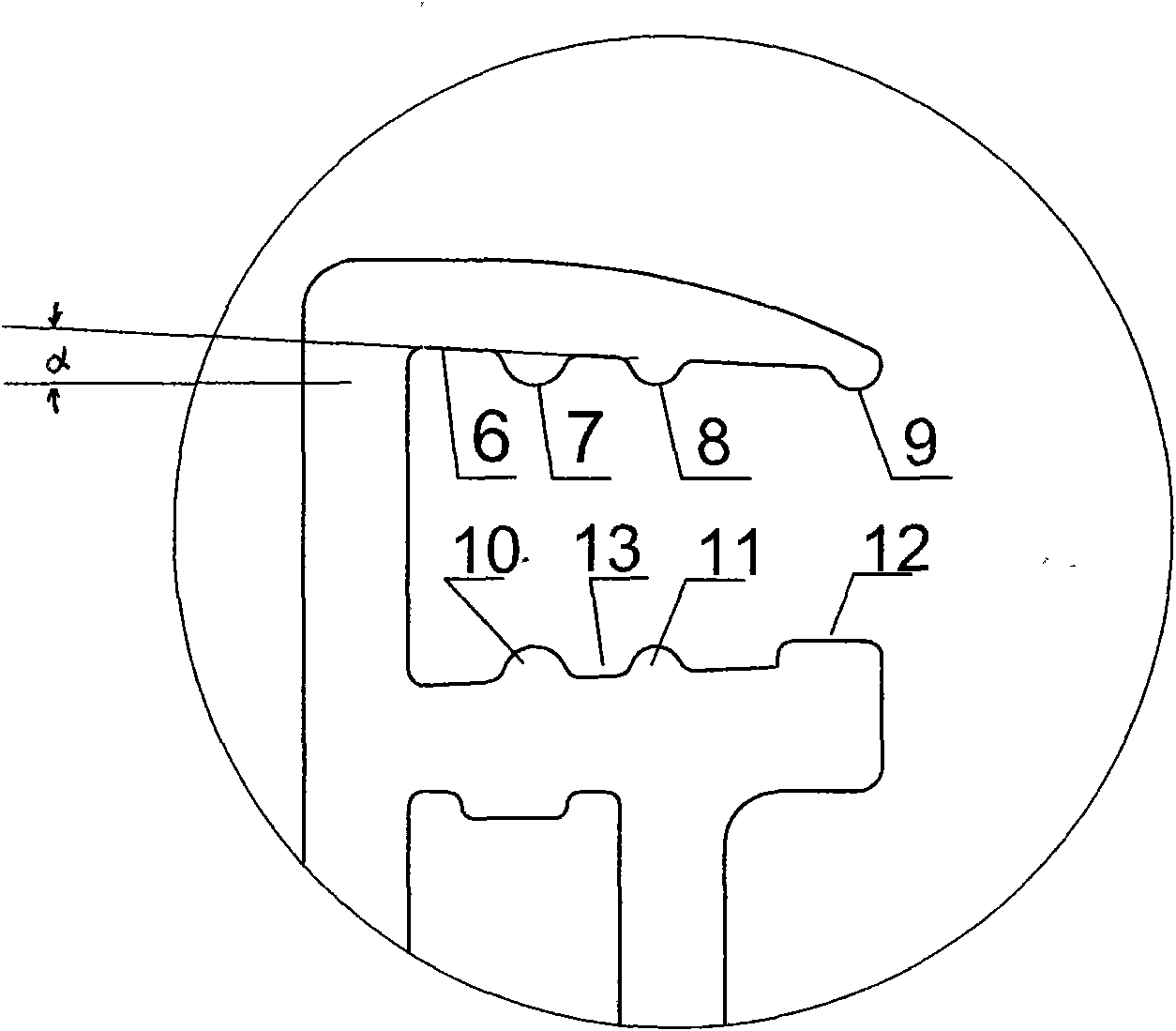

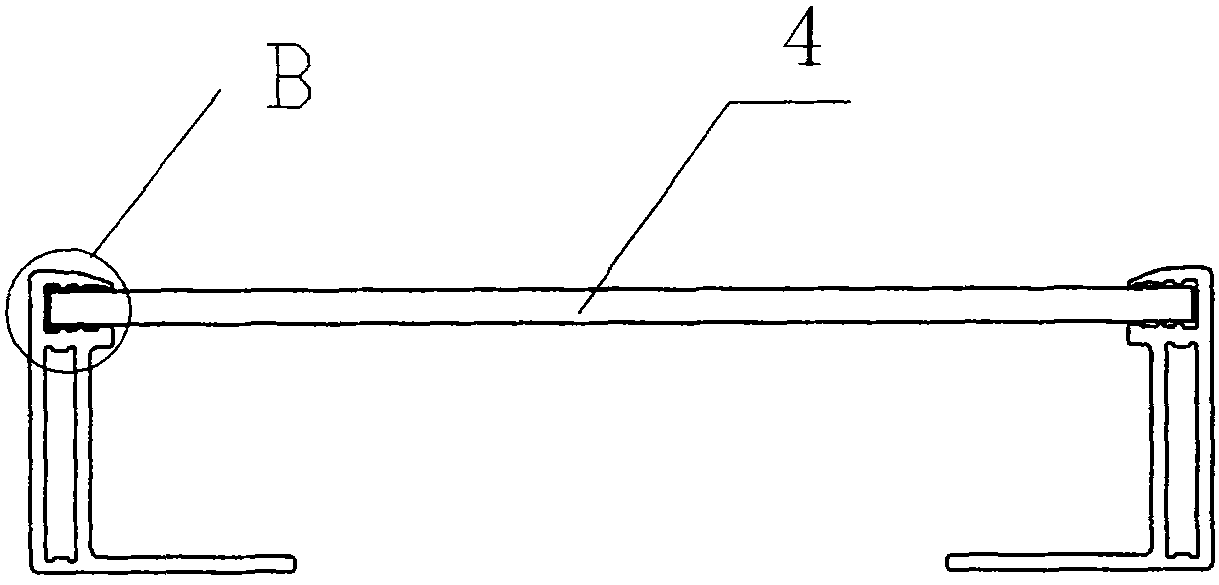

[0038] See attached Figure 1-4 , the improved solar module frame structure shown in Embodiment 1 of the present invention, the whole device is in the shape of an "L" as a whole, and it includes a frame body 1 that clamps a laminate 4, and is connected to the bottom of the frame body 1 The supporting edge 2 and the supporting foot 3, the longitudinal section of the frame frame body 1 is a frame shape with an opening towards the inside, and ribs 7, 8, 9 are distributed on the inner upper surface of the frame frame body, and the inside of the frame frame body Ribs 10, 11, 12 are distributed on the lower surface, and each rib is parallel to the inner side of the frame body. The upper and lower surfaces of the frame body inside the above-mentioned frame body each have an inclination angle of 3°, and the height of ribs 7, 8, 10, 11 Both are 0.85mm, the height of rib 9 is 1.00mm, and the longitudinal section of rib 12 closest to the frame-shaped opening on the inner lower surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com