Fixture for milling two planes of automobile connecting rod cap

An automobile connecting rod and plane technology, applied in the direction of clamping, tool making, support, etc., to achieve the effect of novel structural design, strong practicability, and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

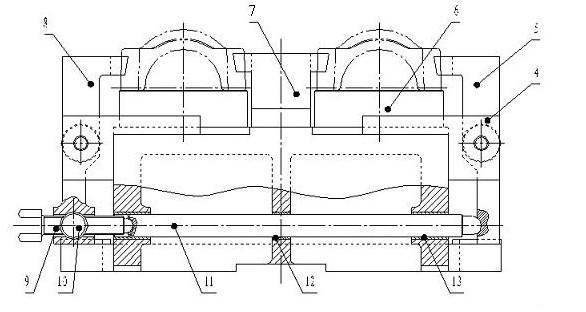

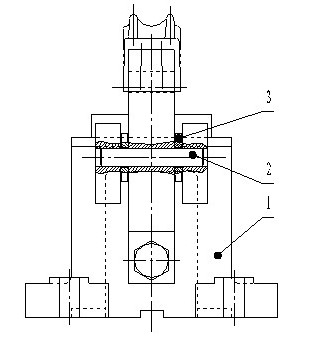

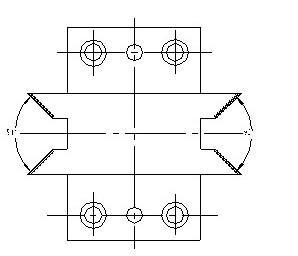

[0014] Embodiment 1: with reference to attached Figure 1-6 . A jig for milling two planes of an automobile connecting rod cover. One end surface of a central shaft 11 is a ball head, and the other end surface is a concave spherical surface. The lower part of the seat surface of the base 1 is in the shape of an inverted mountain. The base 1 is molded by mold casting, and the middle part of the base 1 has a shaft hole horizontally. Steel sleeves 13 are provided at both ends of the shaft hole, and a reinforcing steel sleeve 12 is provided between the two steel sleeves. The central axis 11 is located between the two steel sleeves 13 and the reinforcement steel Inside the sleeve 12, the ball head of the central shaft 11 is in contact with the right pressing plate 5, and the concave spherical surface is in contact with the ball head of the screw rod 9. The right pressing plate 5 has a concave spherical surface and matches the ball head of the central shaft 11. The screw 9 is scre...

Embodiment 2

[0015] Embodiment 2: On the basis of Embodiment 1, a quick clamping method for milling two-plane fixtures of automobile connecting rod covers, the base 1 is fixed on the machine tool used, and two workpieces to be processed are placed on the opening surface of the V-shaped block and In the cavity of the workpiece to be processed formed by the left pressing plate and the right pressing plate, then use a wrench to turn the screw 9, the screw 9 drives the central shaft 11 to move forward, the left pressing plate 8 moves backward, and the central shaft 11 moves forward to push the right pressing plate 5, forcing The left pressing plate 8 and the right pressing plate 5 press the workpiece for processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com