Hydraulic system for sideboom

A hydraulic system and pipelayer technology, applied in the field of hydraulic systems, can solve problems such as inability to overcome walking stability, poor operating comfort, mechanical transmission characteristics, inability to fully utilize engine power, and poor working accuracy of compound actions, etc., to achieve Excellent working characteristics, excellent performance, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

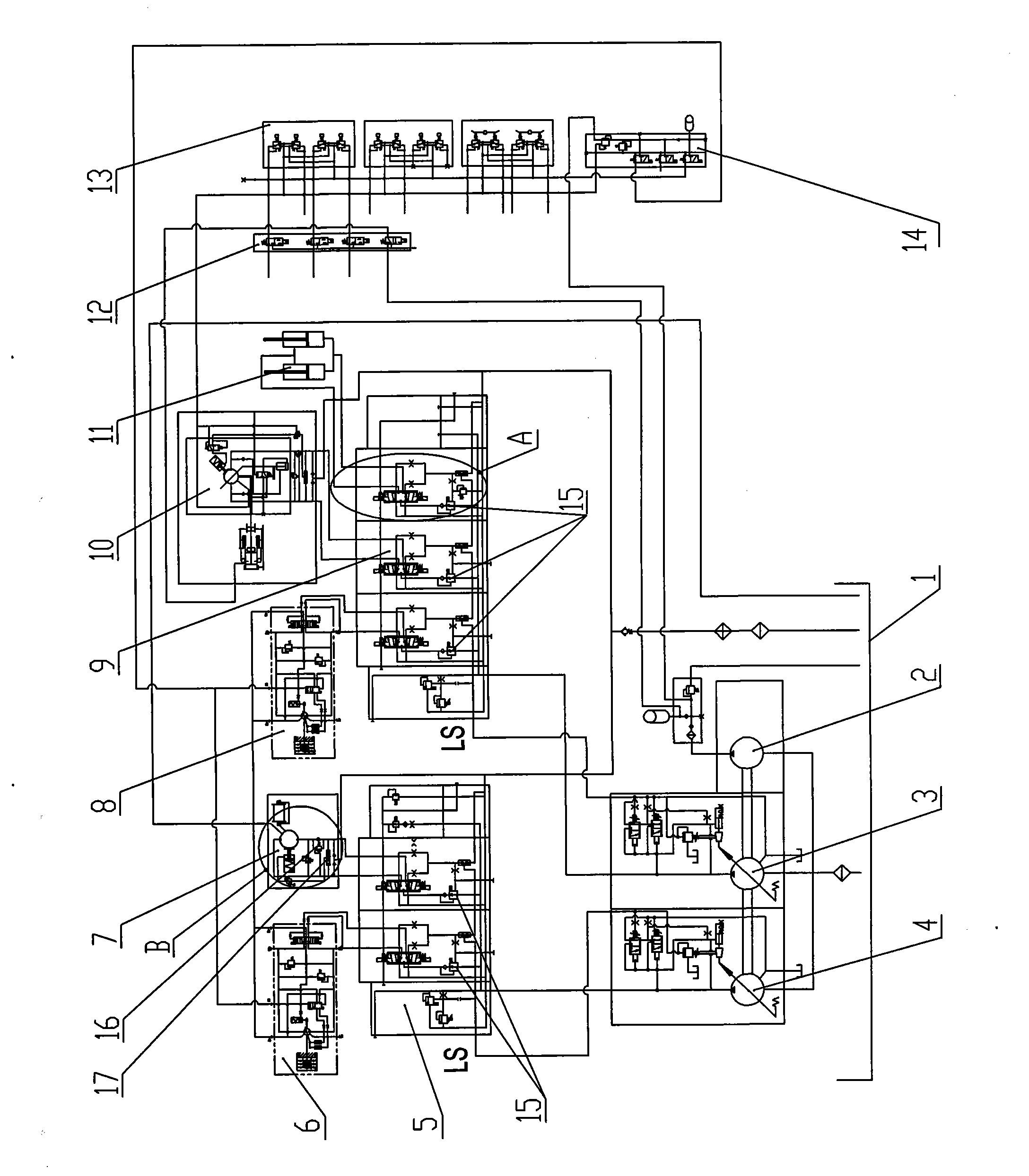

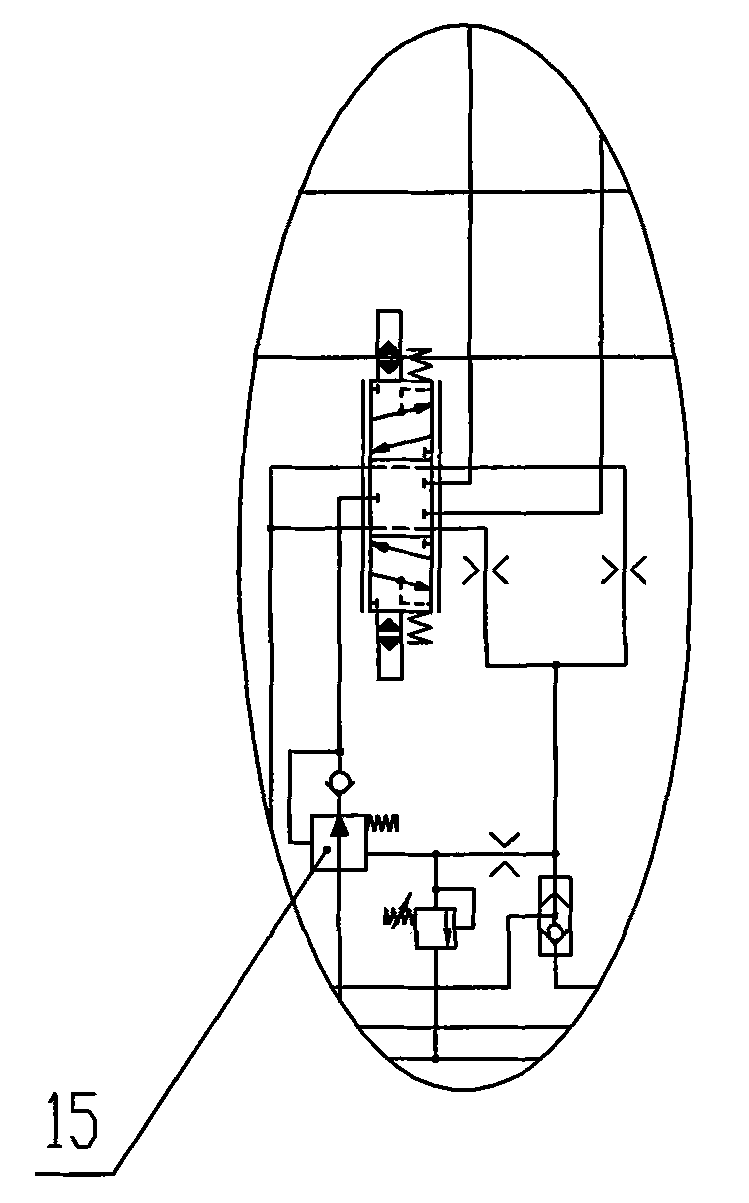

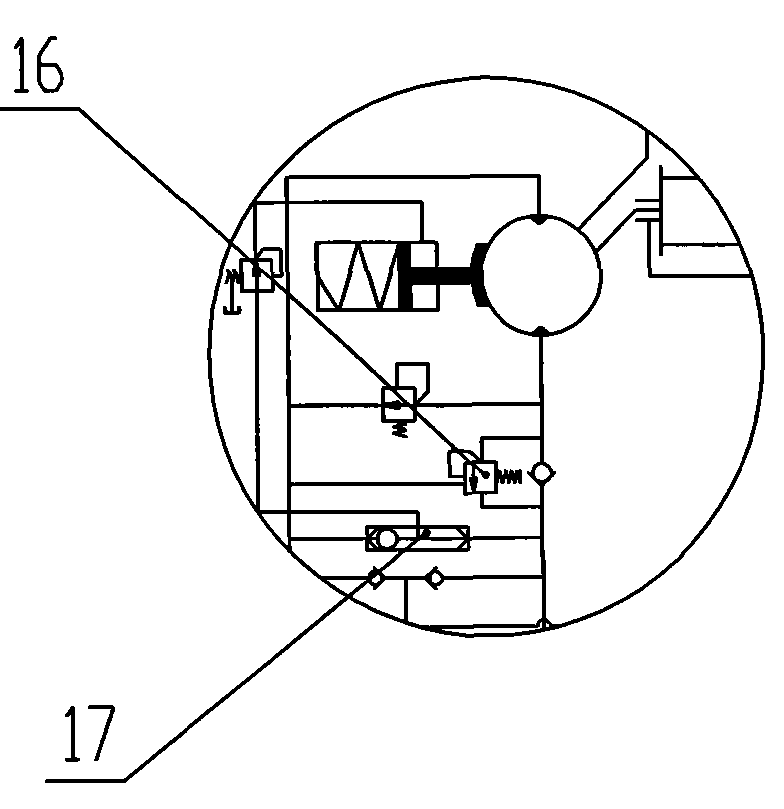

[0022] A hydraulic system for a pipelayer, which is a load sensitive hydraulic system such as figure 1 As shown, the load sensing hydraulic system includes two working pumps: working pump I (3) and working pump II (4), and two multi-way directional valves: multi-way directional valve I (5) and multi-way directional valve Directional valve II (9), and two travel motors: left travel motor 6 and right travel motor 8, working pump I (3), working pump II (4) and pilot pump (2) are triple pumps connected to oil tank 1 To supply oil to the system, pilot pump 2, which is in charge of pilot control and emergency hook throwing, is connected to pilot valve 13 and solenoid valve group II (14) respectively, and working pump I (3) is respectively It is connected with the right traveling motor 8, the hoisting winch 10 and the oil cylinder 11, and the working pump II (4) is connected with the left traveling motor 6 and the luffing hoist 7 through the multi-way reversing valve I (5); the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com