Jet flow aerator

A jet aeration and air intake pipe technology, applied in the field of aerators, can solve problems such as complex equipment structure, unsatisfactory mixing effect, unsatisfactory oxygenation performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

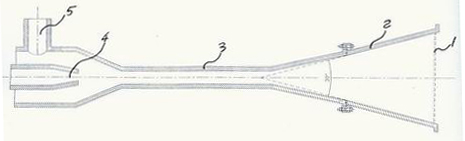

Image

Examples

Embodiment Construction

[0005] Aiming at the shortcomings of the unsatisfactory oxygenation effect of the existing jet aerator, after research and experiments, a net is set at the outlet of the cone tube in the diffusion section of the jet aerator. The net is a stainless steel wire woven net with a mesh size of 5 -8mm, the jet aerator with the net set up through the experiment, because the net cuts the ejected air bubbles twice, the air bubbles are smaller, and the air-water contact area is increased, so the oxygenation effect is improved.

[0006] In addition, in order to further improve the oxygenation effect, the taper of the conical tube in the diffusion section is preferably 29-32°, and the length of the conical tube in the diffusion section is lengthened so that the ratio of the length of the conical tube to the throat section reaches 1:1, and the oxygenation effect is better .

[0007] The working principle of the present invention is that the air bubbles and water produced after the water spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com