Internal-circulation aerobic granule sludge bioreactor

An aerobic granular sludge, bioreactor technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of short gas-water contact time and low oxygen utilization rate. It can achieve the effect of compact structure, high organic removal rate and long circulation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

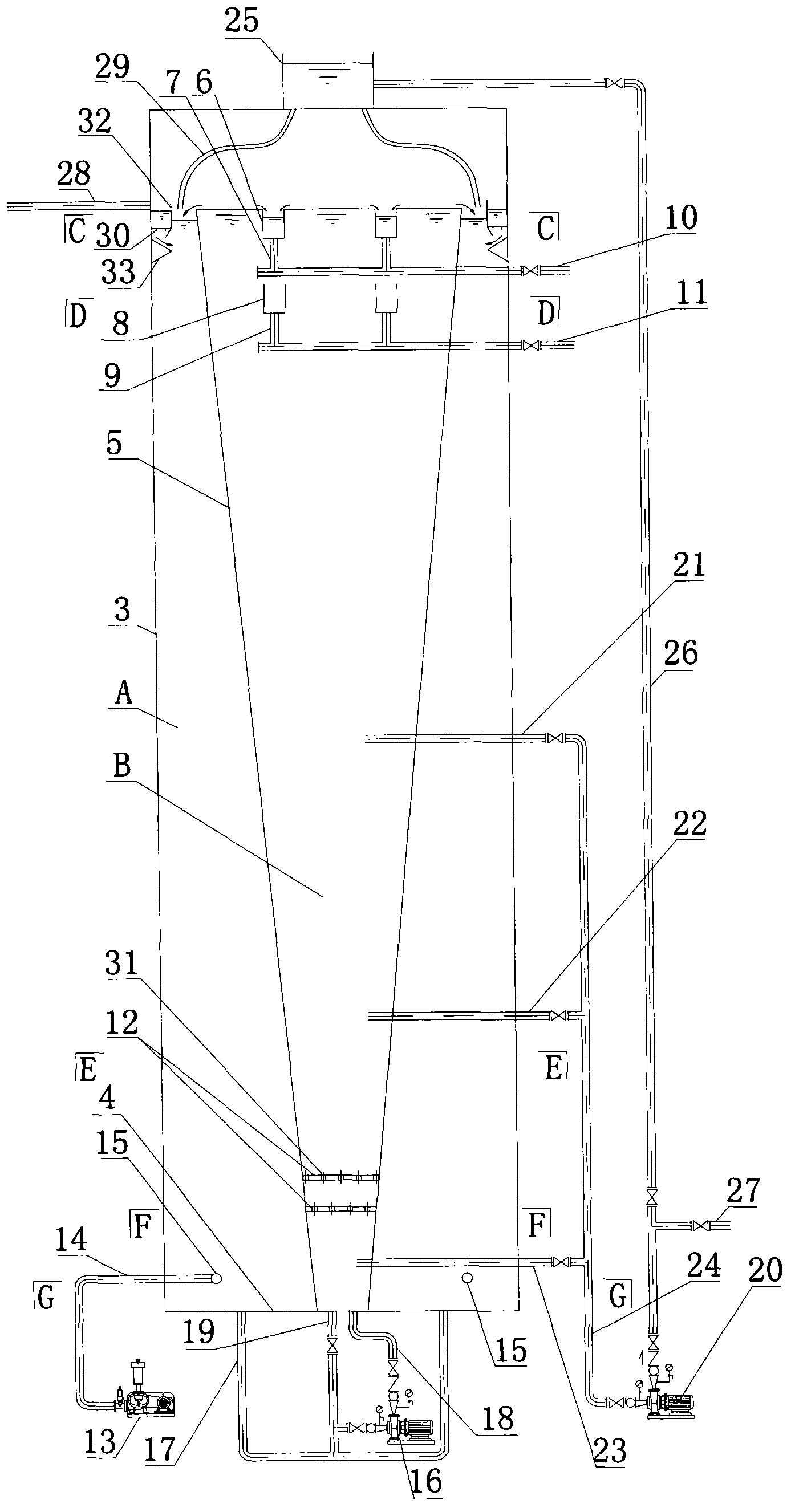

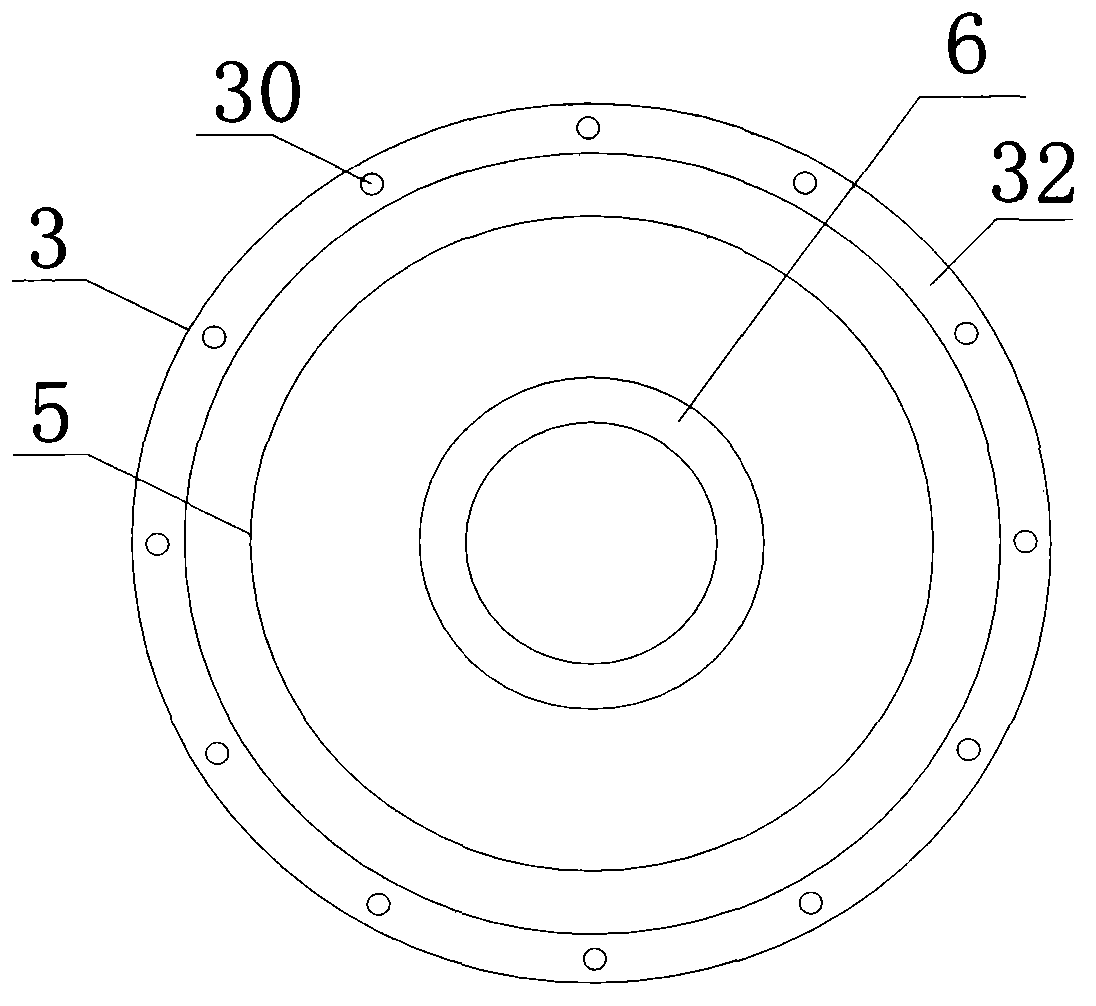

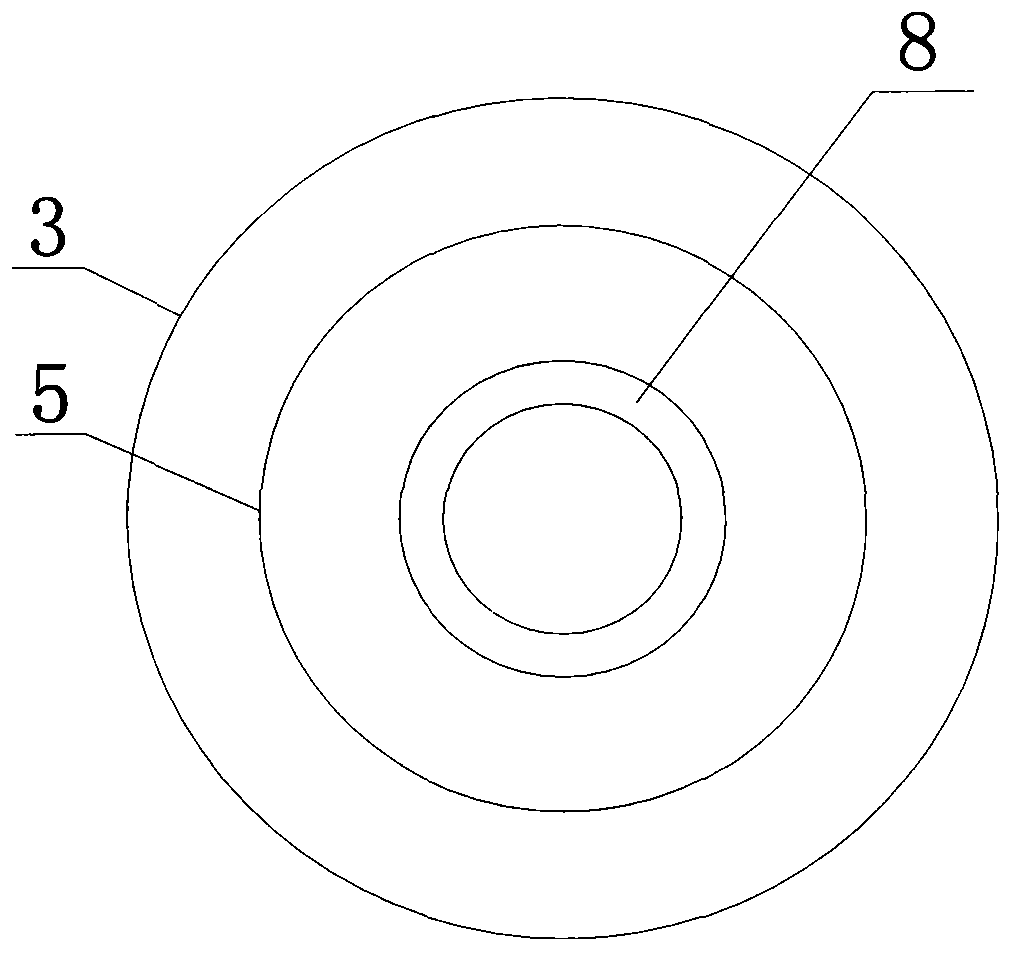

[0073] In the internal circulation aerobic granular sludge reactor, the cylinder body 3 is cylindrical, and the inverted truncated cone cylinder 5 divides the inner part of the cylinder body 3 into the main reaction zone A and the contact filtration zone B, and the upper part of the inverted truncated cone cylinder 5 is not capped. The main reaction zone A and the contact filter zone B are communicated through the communication pipeline at the bottom of the cylinder body 3 or the circulating pump 16 . The cylinder body 3 and the inverted truncated cone cylinder 5 are steel structures, wherein the outer cylinder 3 has a diameter of 6.2m, an effective height of 25m, and a height-to-diameter ratio of 4. The diameter of the bottom of the inverted truncated cone cylinder 5 is 0.5m, and the diameter of the upper bottom is 4.4m. The effective height is 25m. The total effective volume is 754m 3 , of which the effective volume of the main reaction zone is 612m 3 , the effective volum...

Embodiment 2

[0076] Using the reactor described in Example 1, the influent is alcohol waste water, from the IC anaerobic reaction zone, and the water volume is 1500m 3 / d, the influent COD concentration is 2600mg / L, the reaction area is inoculated with the flocculent sludge from the ordinary aeration tank of the municipal sewage plant, after about 30 days of domestication and debugging, a large amount of granular sludge is formed in the reaction area, and the sludge concentration is 6000mg / L, the reaction temperature is 28-30°C. The residence time of wastewater in the main reaction zone is 7.3 hours, and the COD removal rate reaches 92% after the system is stable. The sewage circulation ratio is 100%, the sludge return ratio is 120%, and the COD volume load in the main reaction zone is 5.9kgCOD / m 3 d.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com