Method for preparing fucoidan

A fucoidan sulfate and microwave technology, which is applied in the field of efficient microwave or ultrasonic assisted extraction to prepare fucoidan sulfate, achieves the effect of simple process, low cost, and enhanced immune function of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

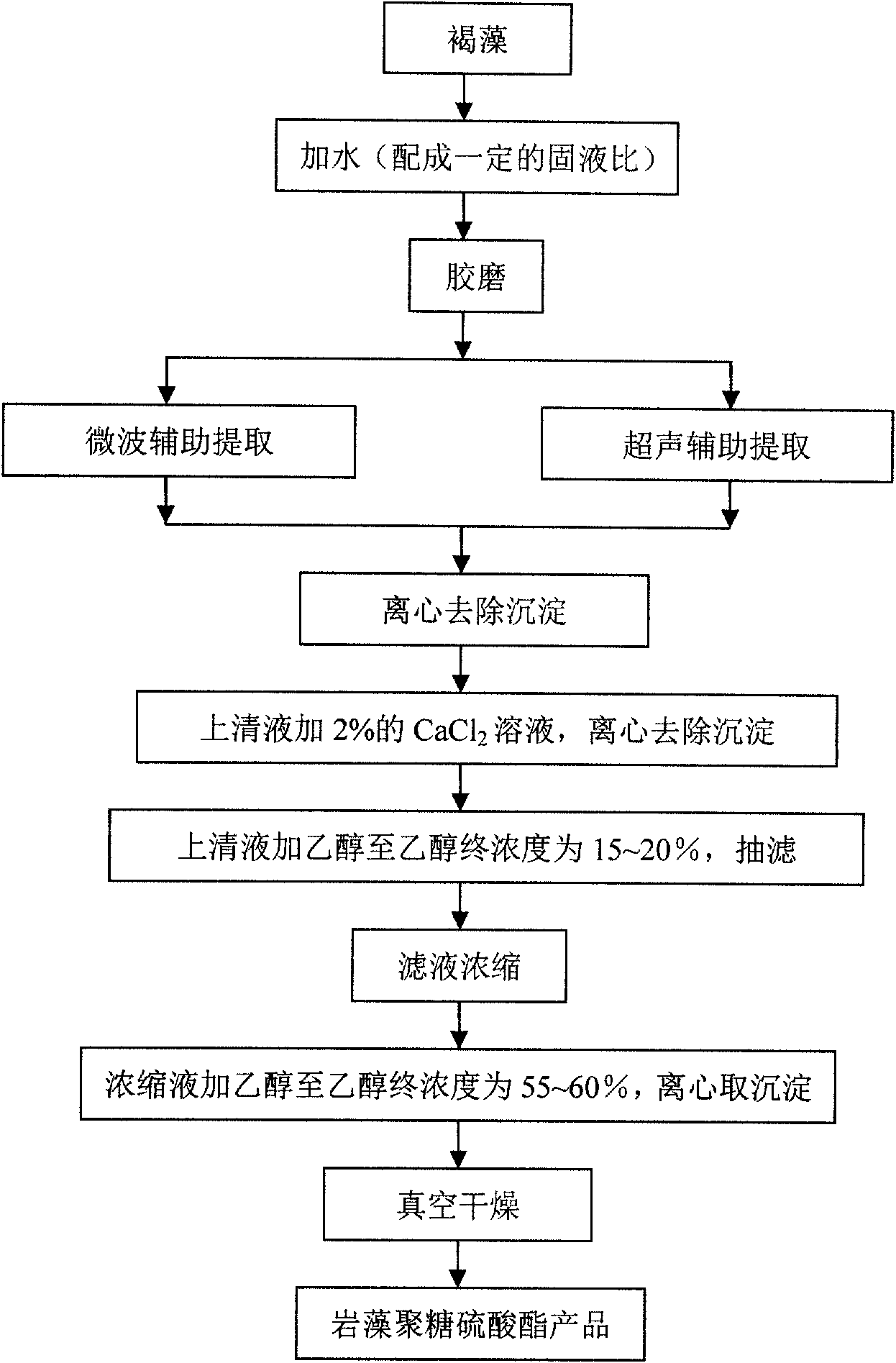

Method used

Image

Examples

Embodiment 1

[0021] Add 1kg of dried kelp to 40L of water, and pour it into a microwave extractor after colloid mill treatment. The microwave extraction process is as follows: microwave time 40min, microwave extraction temperature 80°C, microwave power 450W. After extraction, centrifuge at 5000rpm in a disc centrifuge for 15min, add 400g CaCl to the supernatant 2 , stirred, and placed at room temperature for 24h. After centrifugation at 5000rpm for 15min, 55% ethanol was added until the ethanol concentration in the solution was 20%, suction filtered after stirring, and the suction filtrate was concentrated to 40% of the original volume by a spherical concentration tank. Add 95% ethanol to the concentrated solution until the concentration of ethanol in the solution is 60%, centrifuge at 6000 rpm for 15 minutes after stirring. The precipitate was vacuum-dried to obtain 142 g of yellow-white fucoidan sulfate ester powder with an organic sulfate content of 19.9%.

Embodiment 2

[0023] Add 1 kg of dried wakame seaweed into 50 L of clear water, and pour it into an ultrasonic extractor after colloid mill treatment. The microwave extraction process is as follows: ultrasonic power 1000W, ultrasonic time 40min, ultrasonic extraction temperature 90°C. After extraction, centrifuge at 5000rpm for 10min in a centrifuge, add 500g CaCl to the supernatant 2 , stirred, and placed at room temperature for 24h. After centrifugation at 5000rpm for 15min, 60% ethanol was added until the ethanol concentration in the solution was 20%. After stirring, it was suction filtered, and the suction filtrate was concentrated to 30% of the original volume by a spherical concentration tank. Add absolute ethanol to the concentrated solution until the ethanol concentration in the solution is 60%, centrifuge at 6000 rpm for 15 minutes after stirring. The precipitate was vacuum-dried to obtain 151 g of yellow-white fucoidan sulfate ester powder with an organic sulfate content of 21.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com