Method for extracting haematochrome from purple sweet potato

An extraction method, the technology of purple sweet potato, is applied in the field of natural pigment extraction, which can solve the problems of unsatisfactory extraction rate and complicated process, and achieve the effect of low production cost, simple process steps and high color price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

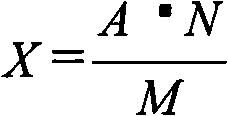

[0028] According to the solid-to-liquid ratio of 1:10, the purple sweet potato was placed in a citric acid aqueous solution with a mass concentration of 0.8%, mashed, extracted at an ultrasonic frequency of 100KHz for 90min, filtered, and the extraction rate in the extract was measured to be 97%. The extract was centrifuged at 1000r / min for 20min, the supernatant was separated and purified by a ceramic ultrafiltration membrane with a molecular weight cut-off of 100KDa, and concentrated in vacuum at 40°C to obtain purple sweet potato red pigment. According to formula 1, its color price is 51.

Embodiment 2

[0030] According to the solid-to-liquid ratio of 1:20, the purple sweet potato was placed in a citric acid aqueous solution with a mass concentration of 0.4%, mashed, extracted at an ultrasonic frequency of 20KHz for 30min, filtered, and the extraction rate in the extract was measured to be 96.5%. The extract was centrifuged at 10,000 r / min for 5 min, the supernatant was separated and purified by a polyethersulfone ultrafiltration membrane with a molecular weight cut-off of 20 KDa, and concentrated in vacuum at 40°C to obtain purple sweet potato red pigment. According to formula 1, its color price is 53.

Embodiment 3

[0032] According to the solid-to-liquid ratio of 1:8, the purple sweet potato was placed in a citric acid aqueous solution with a mass concentration of 0.2%, mashed, extracted at an ultrasonic frequency of 60KHz for 120min, filtered, and the extraction rate in the extract was measured to be 95.5%. The extract was centrifuged at 20000r / min for 10min, the supernatant was separated and purified by a ceramic ultrafiltration membrane with a molecular weight cut-off of 40KDa, and concentrated in vacuum at 40°C to obtain purple sweet potato red pigment. According to formula 1, its color value is 54.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com