Drum-type washing machine and method for manufacturing hanger bracket with damper

A damper and washing machine technology, applied to washing devices, other washing machines, washing machines with containers, etc., can solve the problems of complex assembly, complex structure, and failure to seek rationalization of component functions, and achieve the effect of rationalization of component functions and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

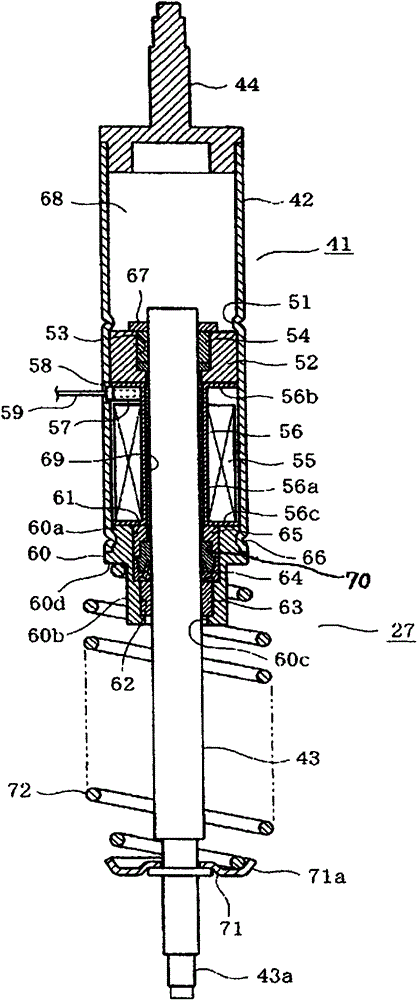

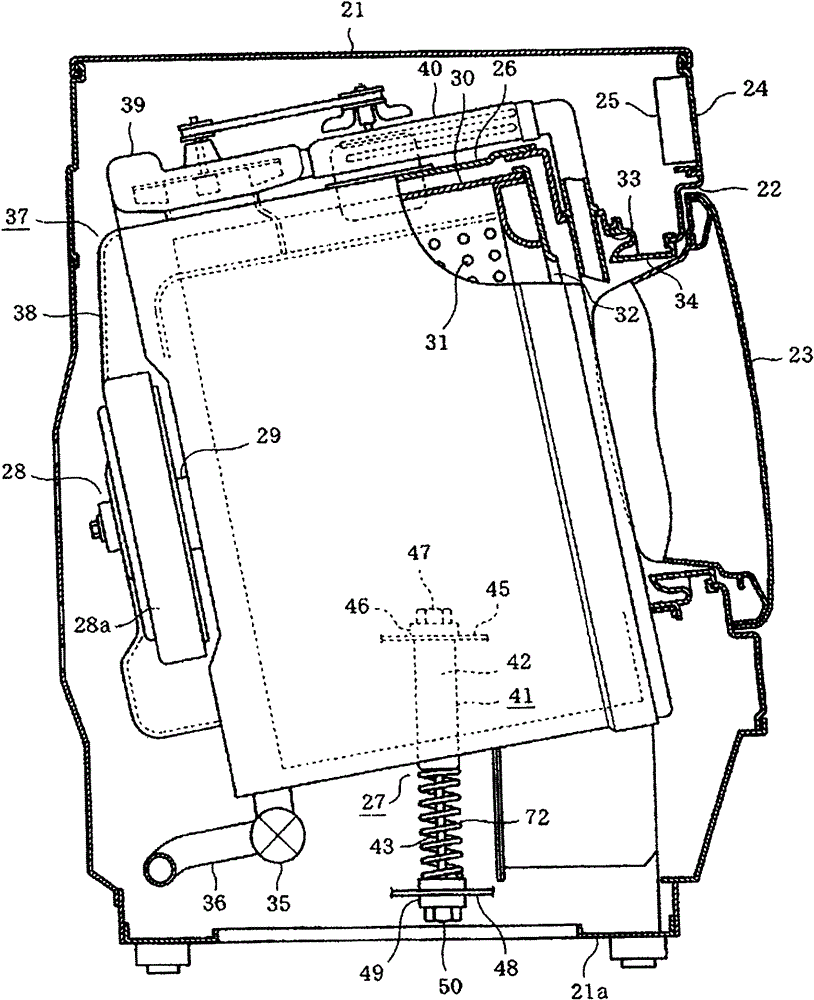

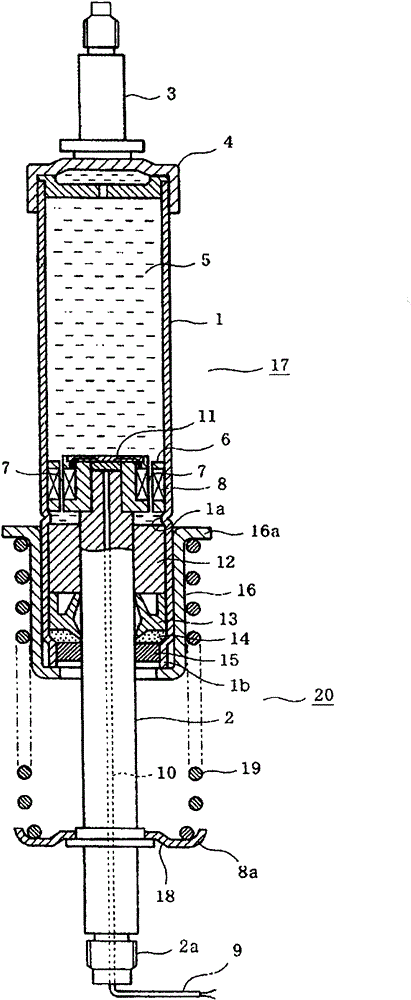

[0035] Below, refer to figure 1 as well as figure 2 One embodiment of the present invention will be described.

[0036] First, in figure 2 The overall structure of the drum type washing machine is shown in , and the outer case 21 is used as the outer shell. At the front portion of the outer case 21 (in figure 2 (center is the right side) is formed with an entrance 22 for putting in and taking out laundry, and a door 23 for opening and closing the entrance 22 is provided at the entrance 22 . Moreover, the operation panel 24 is provided in the upper part of the front part of the outer case 21, and the control device 25 for operation control is provided in the back side (inside the outer case 21).

[0037] A water tank 26 is arranged inside the outer case 21 . The water tank 26 is in the axial direction as the front and rear direction ( figure 2 The water tank 26 is elastically supported on the bottom plate 21a of the outer box 21 by a pair of left and right (only one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com