Blade pitch lock device

A locking device and blade technology, applied in wind power generation, engine components, wind turbines, etc., can solve the problems of dependence, increase the risk of failure, expensive, etc., and achieve the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following detailed description and the examples contained therein are provided merely for the purpose of describing and illustrating certain embodiments of the invention, and they are not intended in any way to limit the scope of the invention.

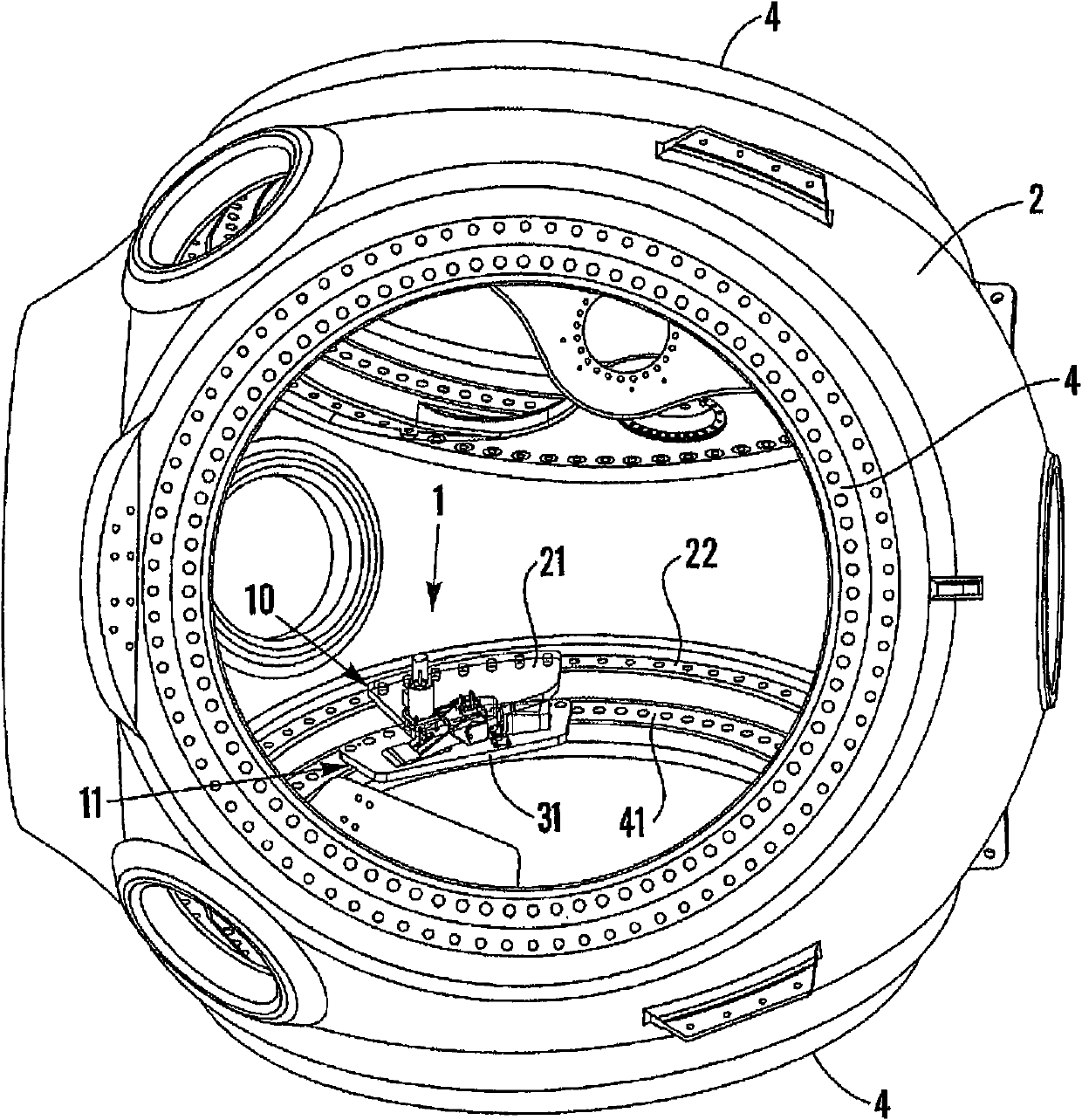

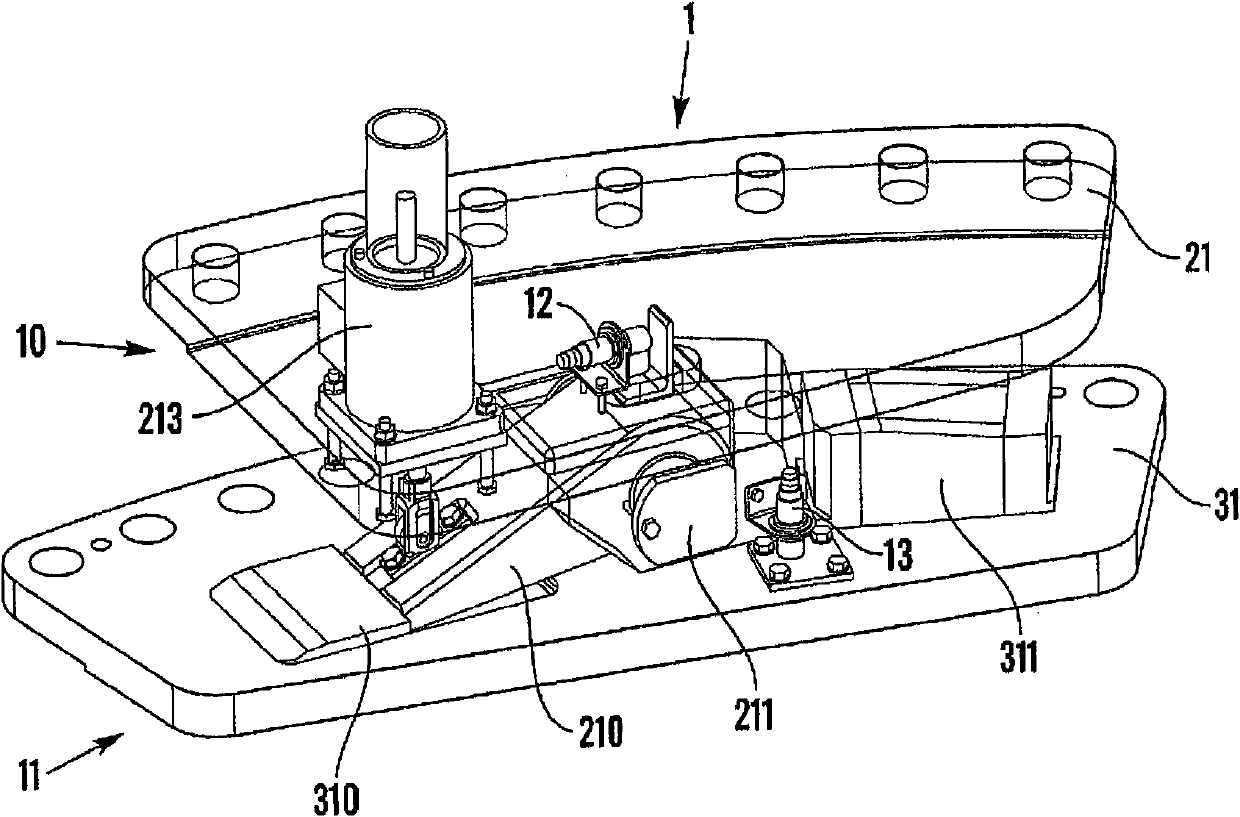

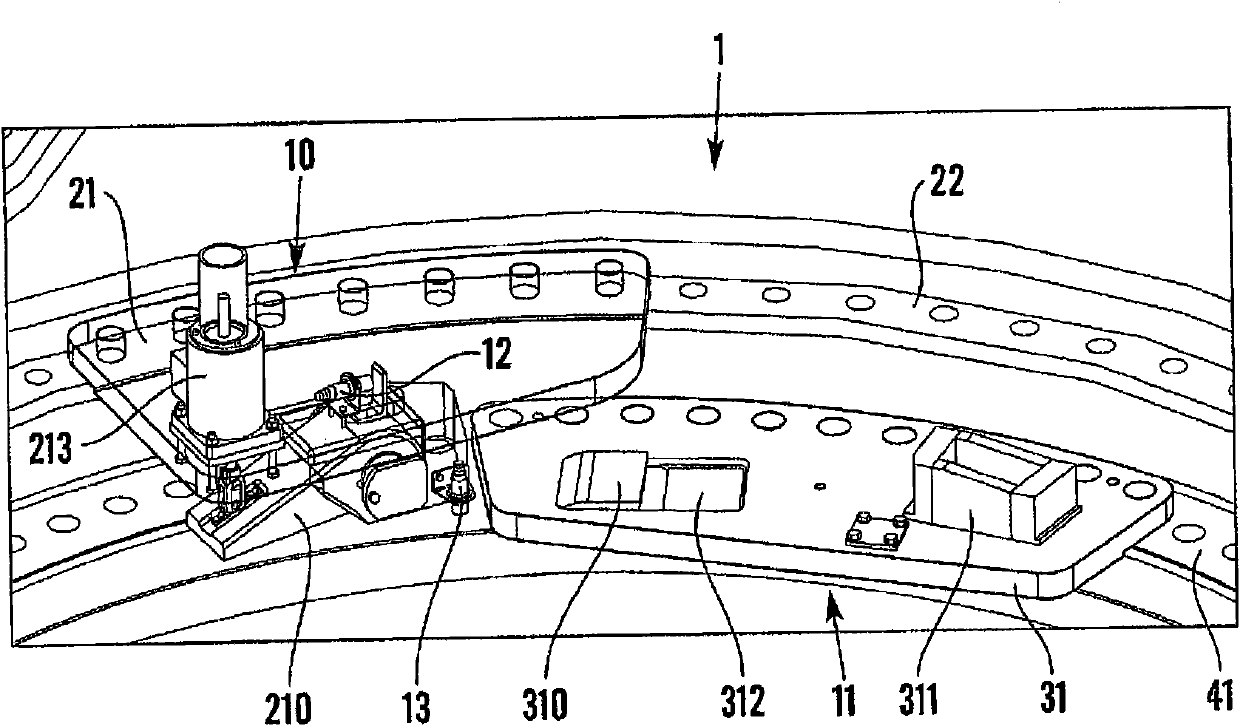

[0024] figure 1 A rotor hub 2 of a wind energy plant is shown with three pitch bearings 4 each intended to receive a turbine blade (not shown). Each pitch bearing 4 comprises an annular flange 22 connected to the hub 2, and an annular bearing ring 41 configured for operative connection with a rotor blade. A pitch bearing 4 is seen comprising a locking device 1 according to the invention. figure 1 The locking device 1 in is shown in a locking mode, thereby preventing a blade (not shown) from rotating about its longitudinal axis relative to the rotor hub 2 . as by figure 1 As shown, the locking device 1 comprises a hub part 10 connected to the flange 22, and a blade part 11 connected to the bearing ring 41 of the rotor bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com