LED lamp structure and heat dissipation method thereof

A technology of LED lamps and heat dissipation methods, which is applied in the direction of lighting and heating equipment, cooling/heating devices of lighting devices, and damage prevention measures of lighting devices. The heat dissipation conditions are consistent and the effect of increasing the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

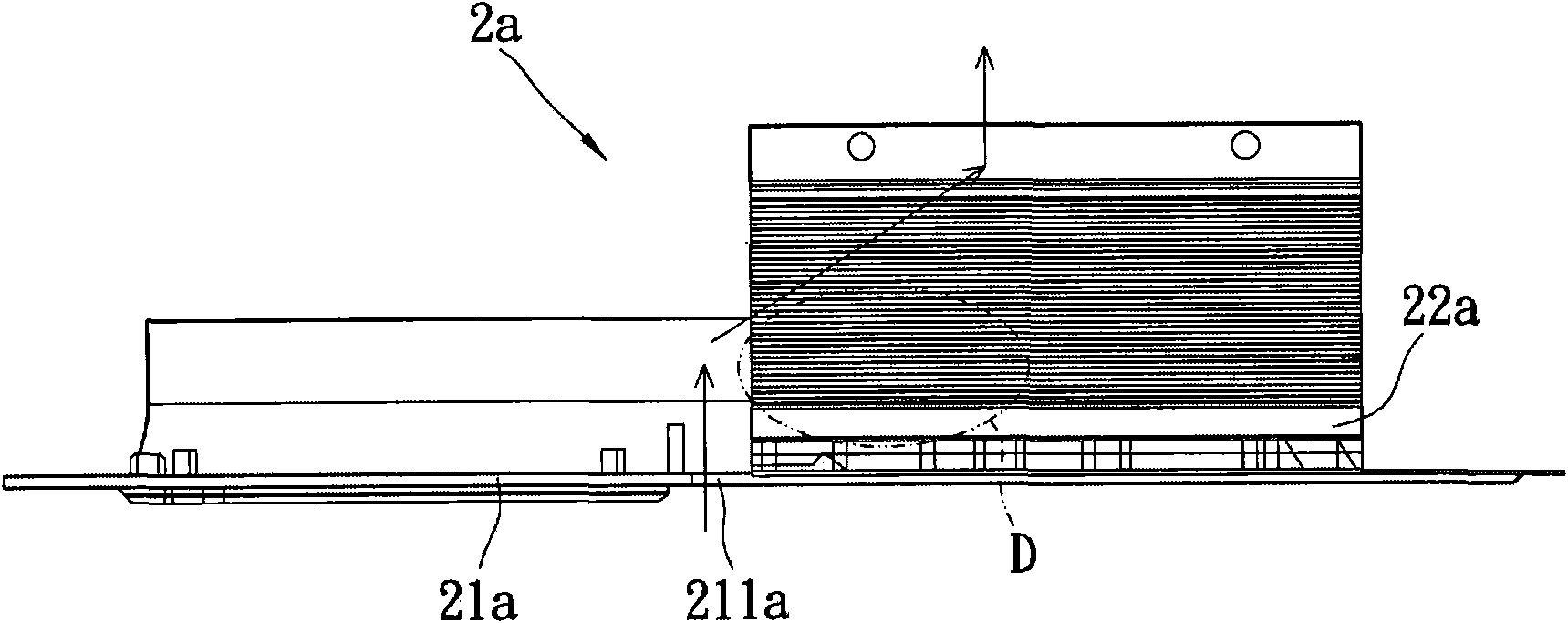

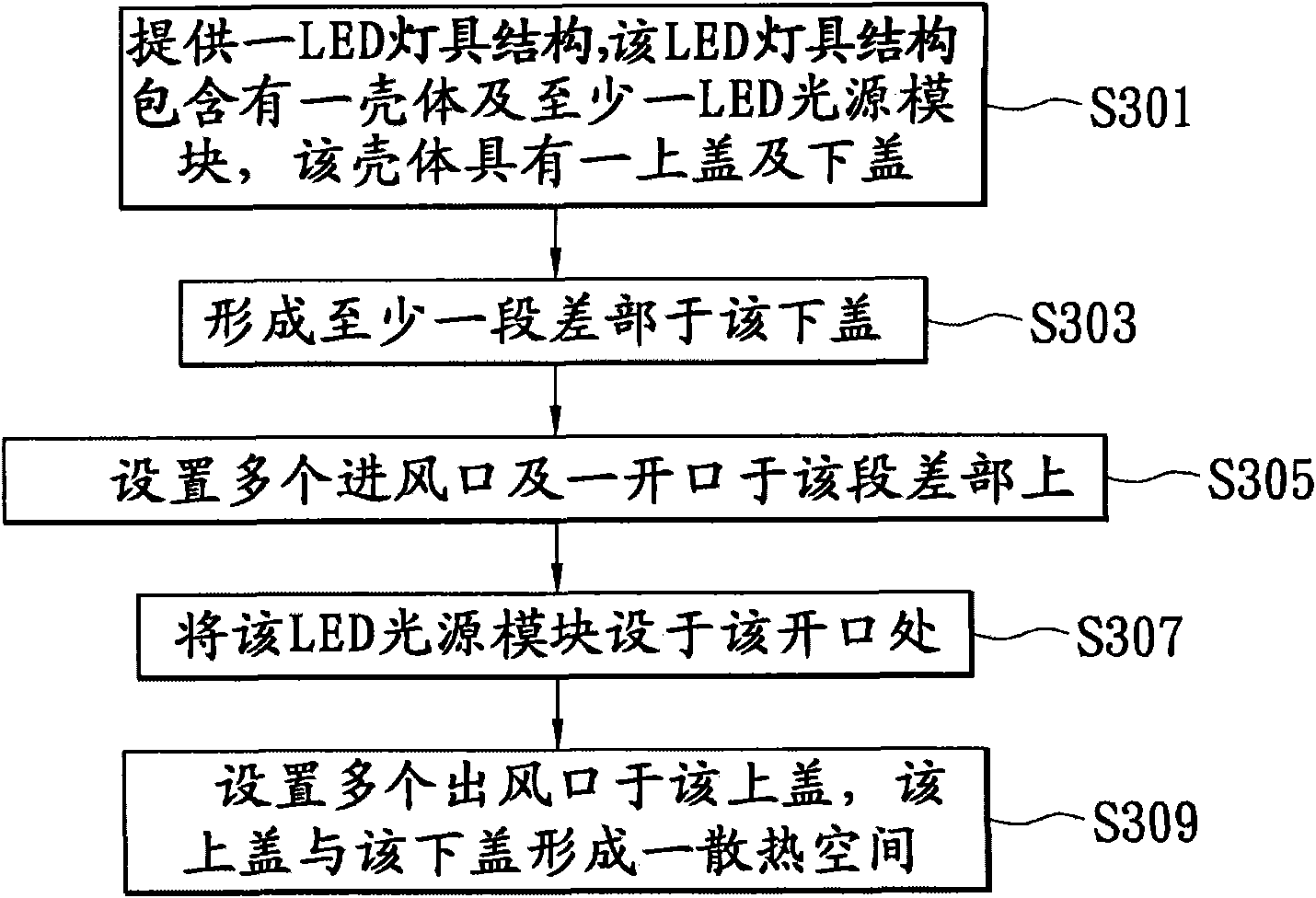

[0065] see Figure 4 to Figure 8 , The present invention provides an LED lamp structure, including: a casing 1 , at least one LED light source module 2 and a power supply 3 .

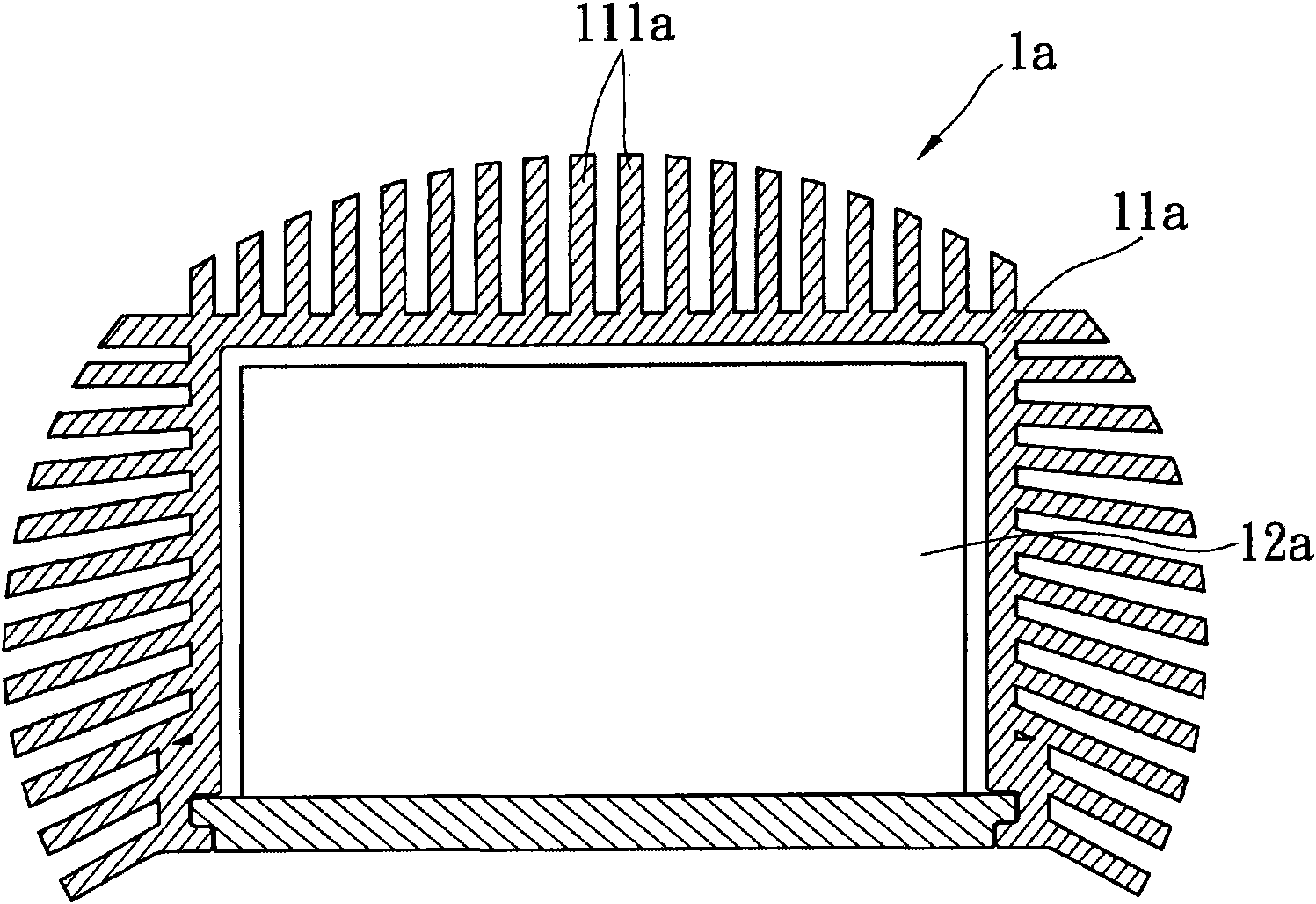

[0066] The housing 1 is a hollow box, which can be made of sheet metal or plastic. The casing 1 includes a cover 11 and a base 12 . In the present embodiment, the cover 11 is pivotally mounted on the base 12 , but not limited thereto. The cover 11 and the base 12 form a cooling space 13 .

[0067] The cover body 11 is provided with a plurality of air outlets 111 , a plurality of depressions 112 and a groove 113 . The air outlets 111 of the cover 11 are elongated, spaced apart from each other on the top of the cover 11 , and located on two sides of the groove 113 . These recesses 112 are respectively located at the air outlet 111 and are vertically lower than the cover 11 . Two ends of the recesses 112 are respectively connected to the cover 11 to prevent dust or rainwater from directly entering the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com