Vertical oil heater radiator and oil heater applied same

A heat sink and heat sink technology, applied in applications, household heating, heating methods, etc., can solve problems such as heat shortage of heat sinks, limited number of heat sinks, inability to heat, etc., achieve high space utilization and promote circulation flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

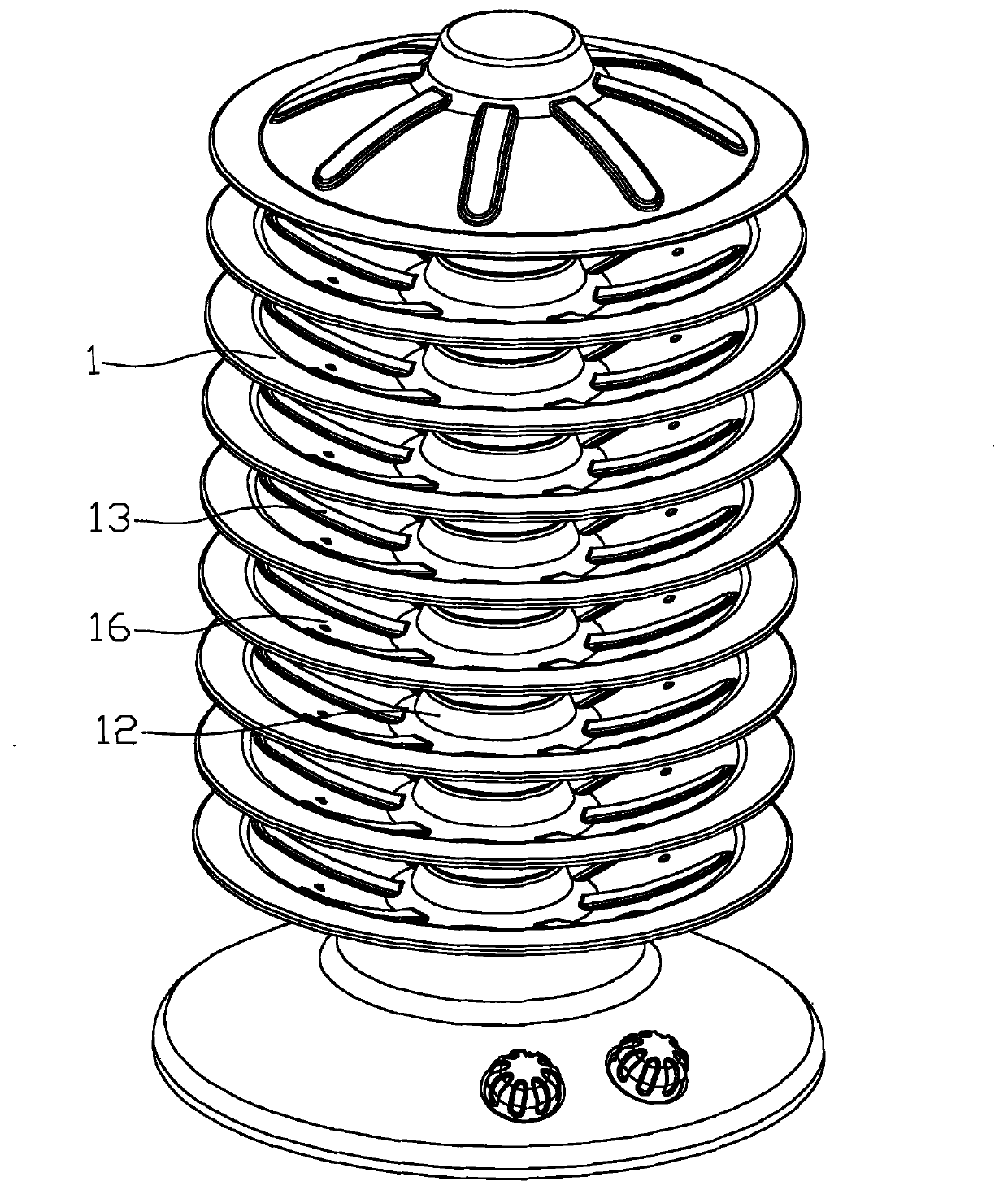

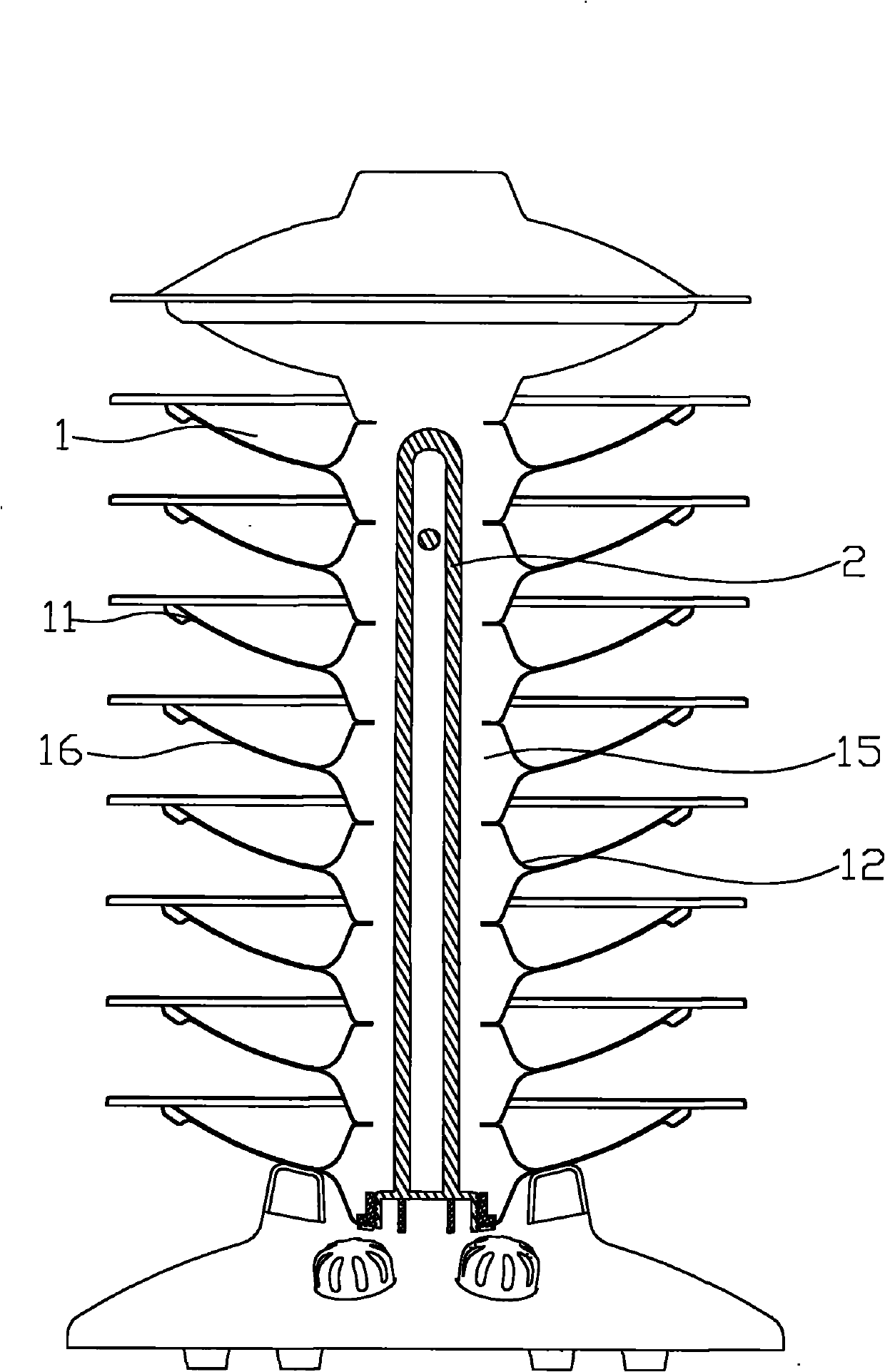

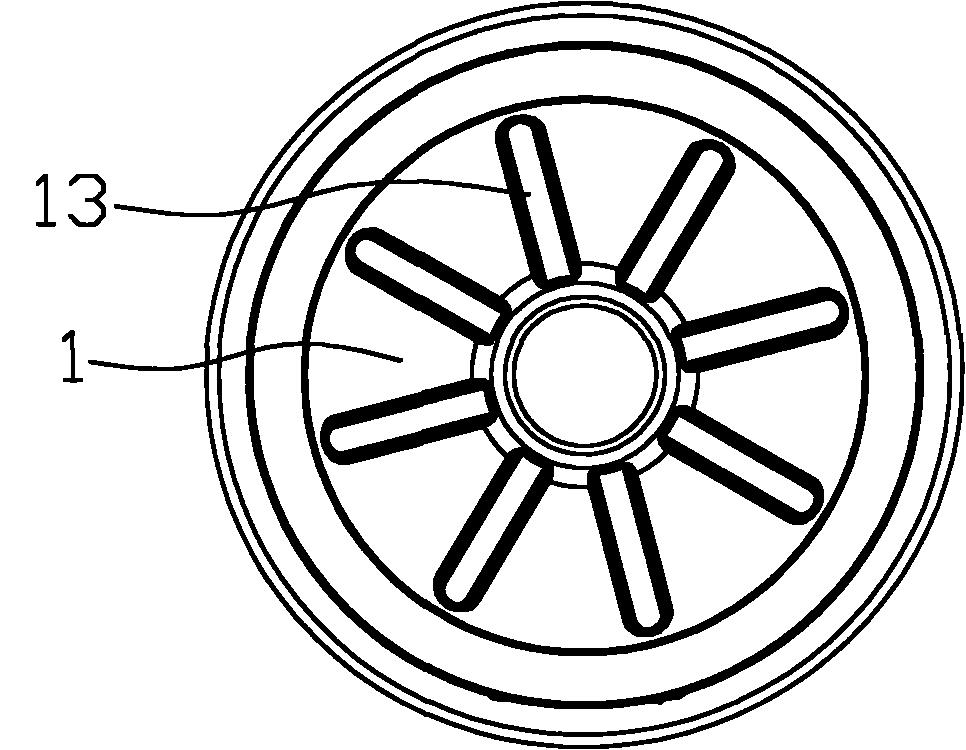

[0028] Embodiment 1: as Figure 1 to Figure 4 As shown in the vertical oil heater and its heat sink, the vertical oil heater used in the present invention is mainly composed of a heating element 2, a plurality of heat sinks 1, a temperature control element, a power switch, an indicator light, a base, etc., wherein the heating element 2. The temperature control element, power switch, and indicator light are all installed on the base, and multiple heat sinks 1 are connected to form a heat sink. The heat sink is placed vertically and longitudinally, and is sealed and connected with the base to form a sealed internal storage. oil space. The base can be arranged under or above the radiator, preferably, the base is arranged under the radiator. The other side of the radiator is also provided with a cover plate. When the oil temperature of the heat-conducting oil in the oil tank reaches a predetermined temperature, the temperature control element will cut off the power supply by its...

Embodiment 2

[0033] Embodiment 2: as Figure 5 to Figure 7 As shown in the vertical oil cooler and its heat sink, in this embodiment, the heat sink 1 of the heat sink is flower-shaped from the outside, and the flower-shaped heat sink 1 includes two petals 14, which is an ellipse. Each petal portion 14 is bent upwards from the inside to the outside as a whole, that is, the ends of the two major axes of the ellipse are bent upwards as a whole. like Figure 7 As shown, the projections of the petals 14 of adjacent flower-shaped heat sinks 1 on the horizontal plane are staggered at 90 degrees, so as to improve the efficiency of each heat sink 1 in heating air. Other design schemes of the vertical oil cooler and its radiator in this embodiment can be implemented with reference to Embodiment 1, and will not be repeated here.

Embodiment 3

[0034] Embodiment 3: as Figure 8 to Figure 9The shown vertical oil cooler and its heat sink, in this embodiment, the heat sink 1 of the heat sink is flower-shaped from the outside, and the flower-shaped heat sink 1 includes three petal parts 14, and each petal The portion 14 is bent upwards from the inside to the outside as a whole. like Figure 9 As shown, the projections of the petals 14 of adjacent flower-shaped heat sinks 1 on the horizontal plane are staggered at 60 degrees, so as to improve the efficiency of each heat sink 1 in heating air. Other design schemes of the vertical oil cooler and its radiator in this embodiment can be implemented with reference to Embodiment 1, and will not be repeated here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap