Method for testing key performance of drive shaft assembly of constant velocity universal joint

A technology of constant velocity joints and testing methods, applied in the direction of machine gear/transmission mechanism testing, etc., can solve problems such as instability, inability to comprehensively reflect the relative changes of displacement, swing angle and sliding force, and difficulty in ensuring the stability of loading torque. , to achieve the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the invention, and the detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

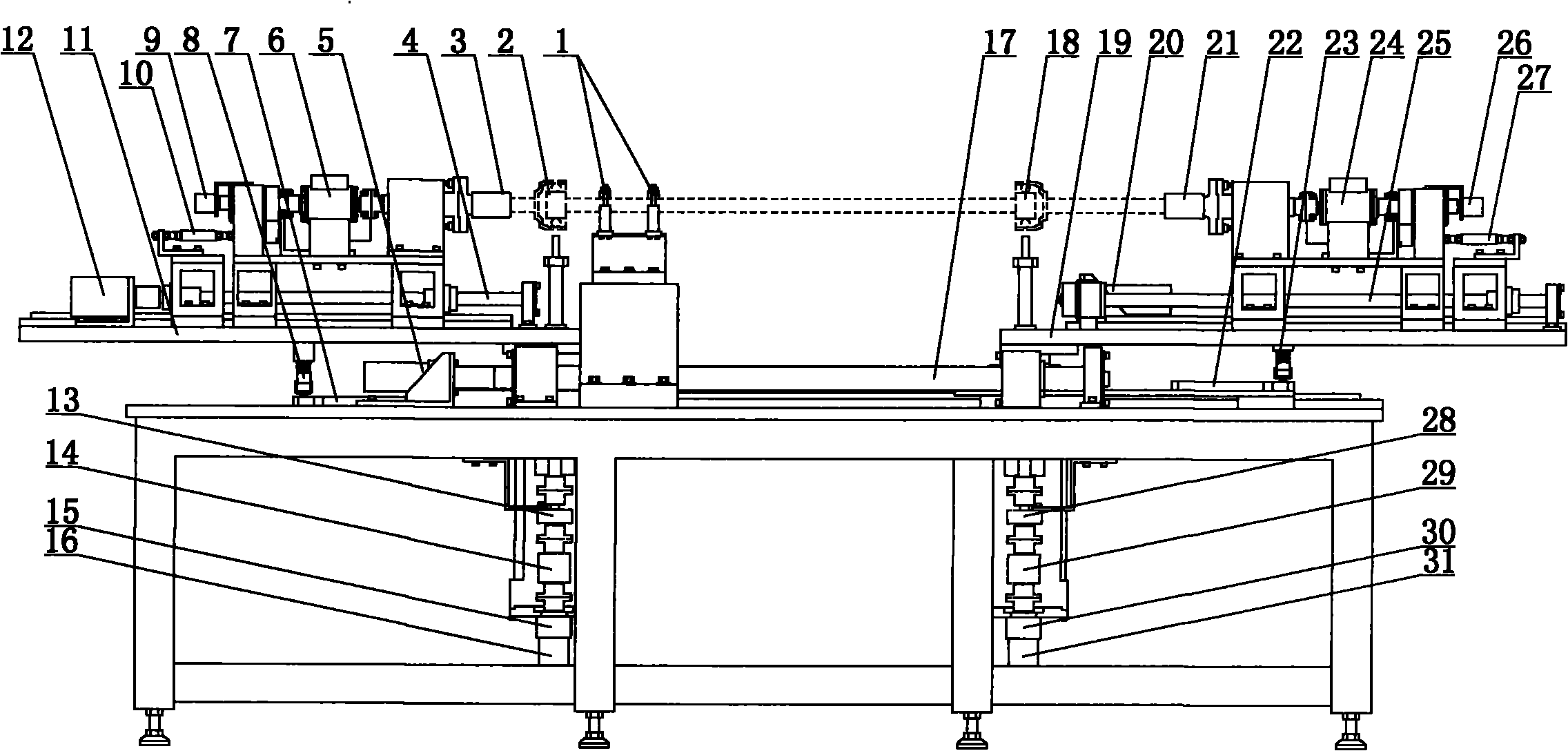

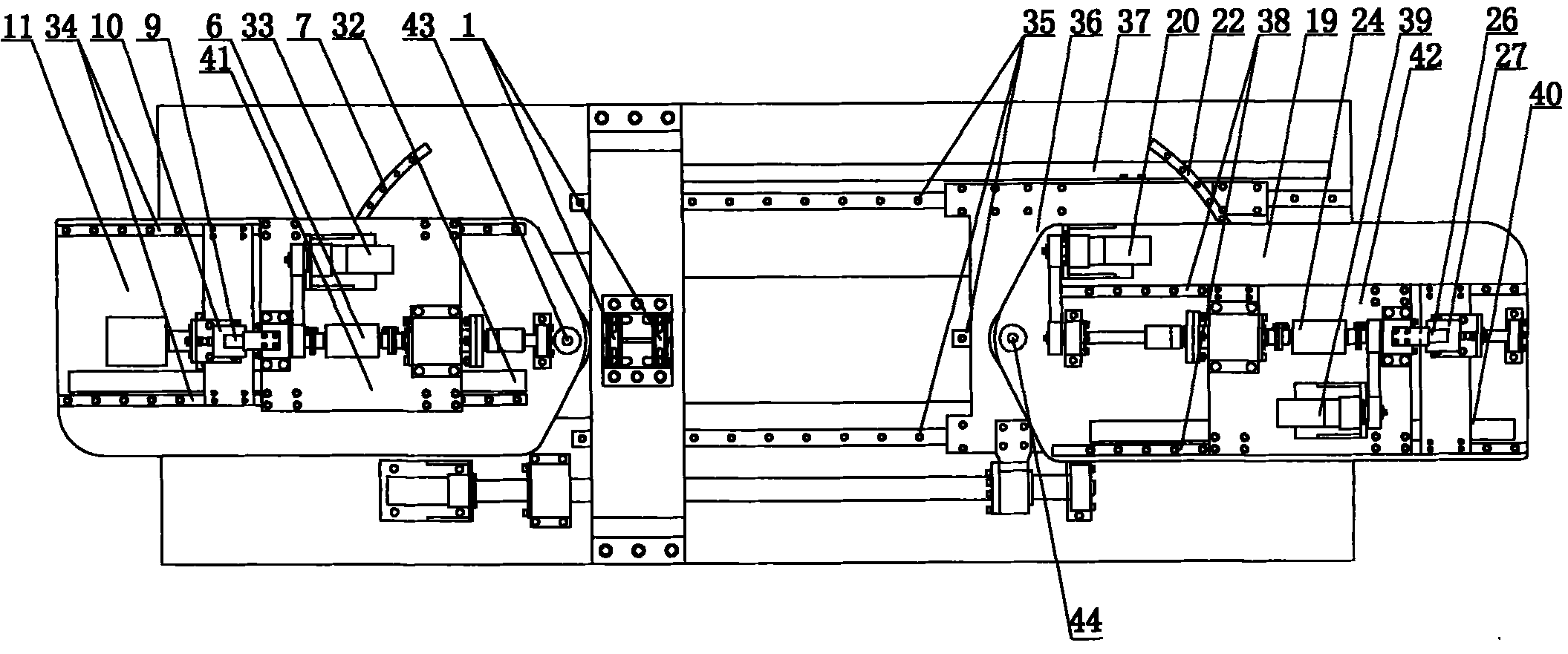

[0026] The target to be tested is the constant velocity universal joint drive shaft assembly for the left rear wheel of a rear-drive car. The test items are the characteristics of the swing moment and swing angle, the comprehensive characteristics of displacement, swing angle and slip force, and the gap characteristics of the assembly. example in the test such as figure 1 and figure 2 performed on the test system shown. The test system includes: fixture 1, fixed end universal joint chuck 3, fixed end small slide table screw 4, mobile end large slide table motor 5, fixed end torque sensor 6, fixed end swin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com