System and method for monitoring power filters and detecting power filter failure in wind turbine electrical generator

A technology of power filter and wind turbine, which is applied in the direction of electric power measurement through current/voltage, wind power generation, capacitor testing, etc., and can solve problems such as difficult to find installation and maintenance parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

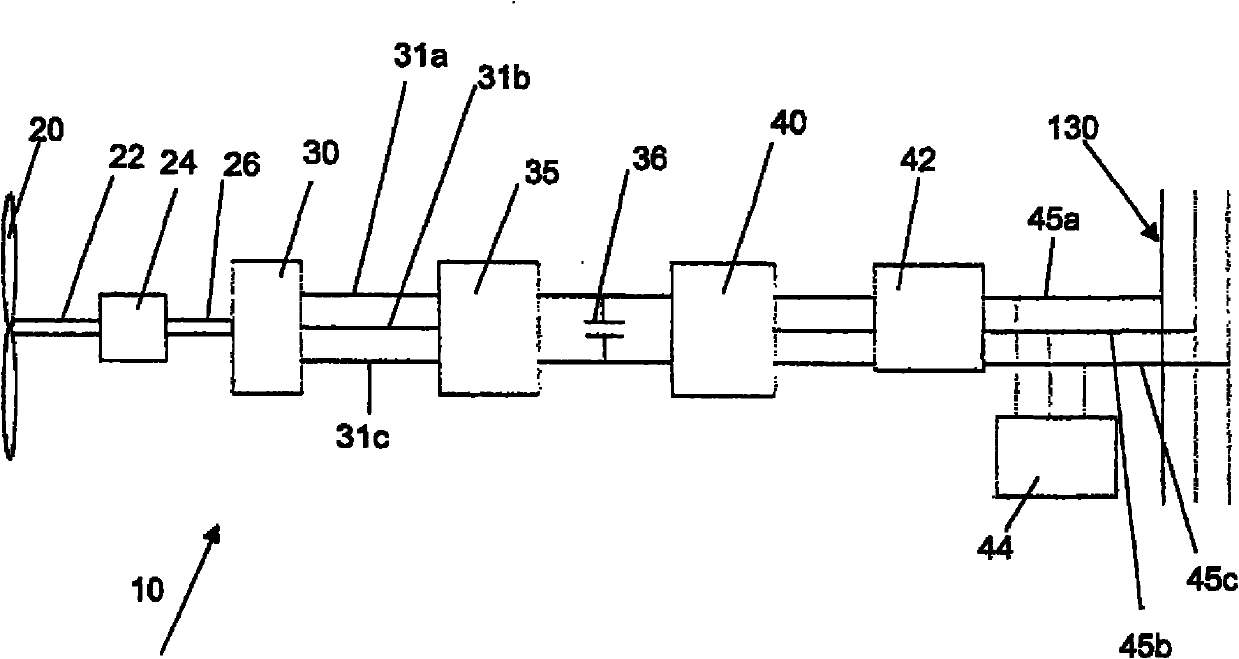

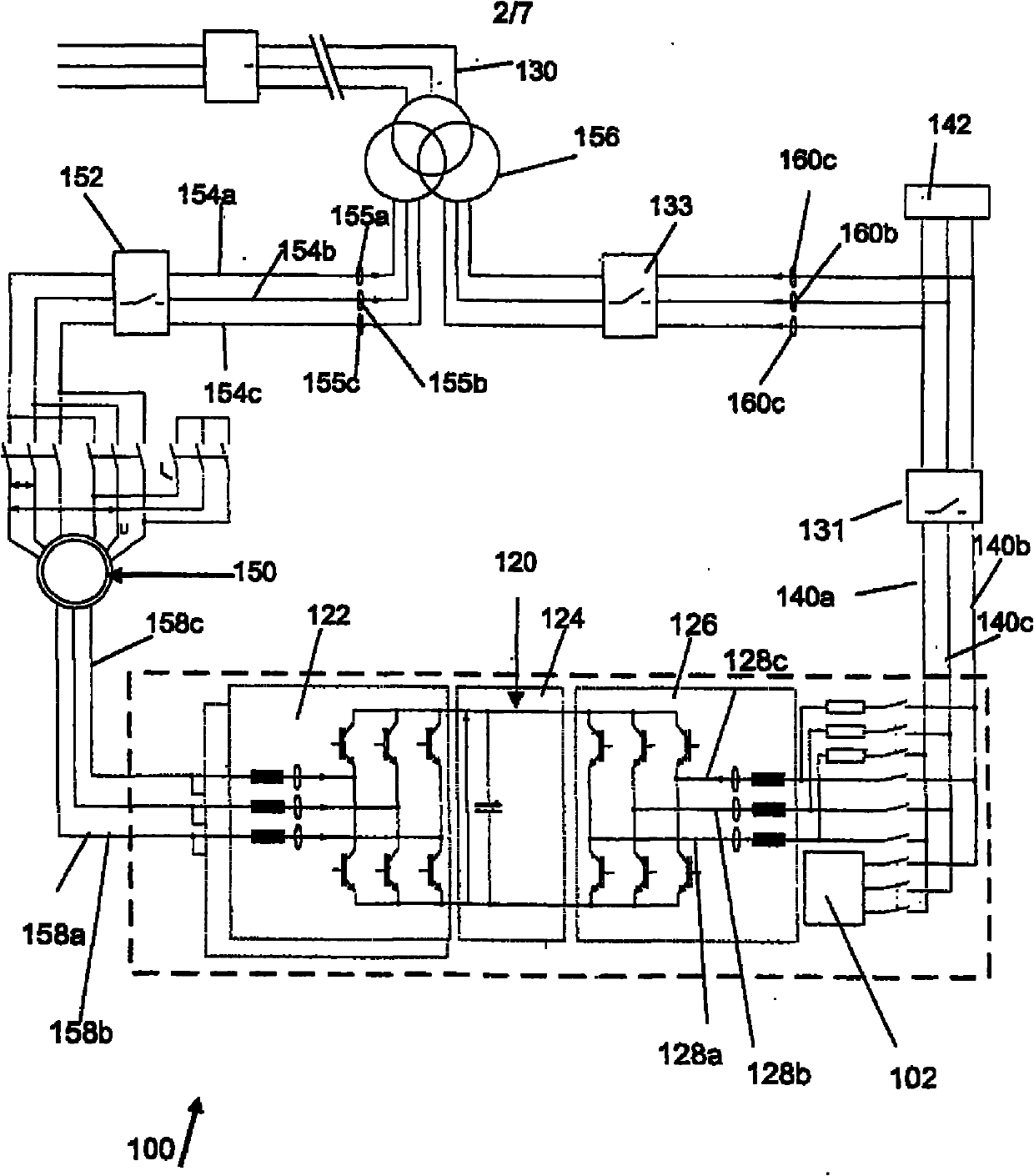

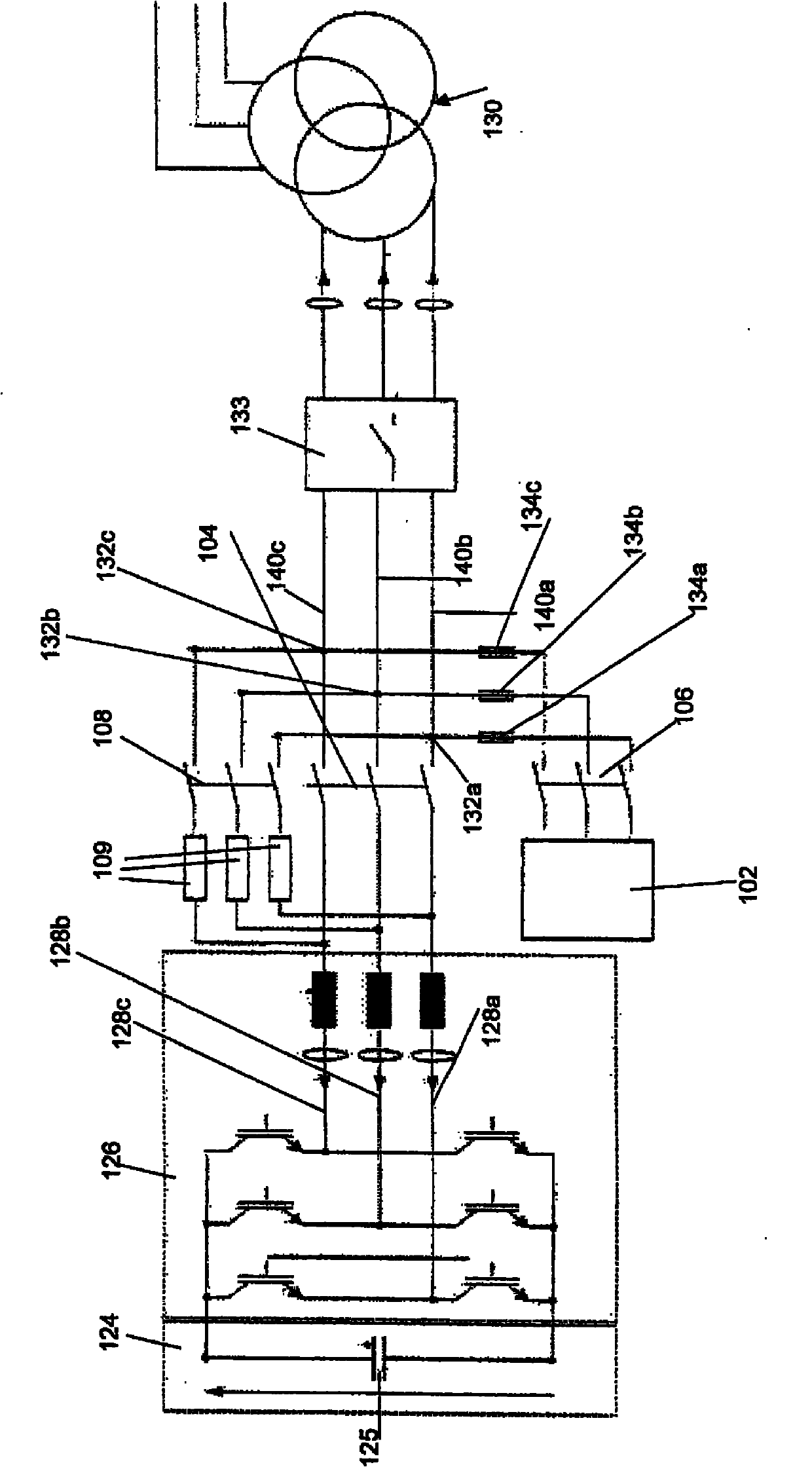

[0037] Embodiments of the present invention provide a system and method for alerting an operator of a power generation system of power filter failure without installing additional hardware components. For example purposes, one embodiment of the present system and method will be described below with respect to a wind turbine generator generating three-phase electrical power. However, it should be understood that other types and sizes of generators, including single-phase and multi-phase, may be used without departing from the scope of the present embodiment as defined in the appended claims. As examples, embodiments of the present invention may use double / single-fed induction generators, synchronous generators, asynchronous generators, and other types of generators known to those skilled in the art, synchronous generators including permanent magnet (PM) generators Generators, internal permanent magnet (IPM) generators and surface mounted permanent magnet (SMPM) generators, asyn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com