Remote on-line calibration method for magnetic sensor

A technology of magnetic sensor and calibration method, applied in the direction of instruments, measuring devices, measuring electrical variables, etc., can solve the problems of easily damaged magnetic sensors, complicated calibration work, inability to realize remote online calibration, etc., and achieve the effect of simple steps and reliable methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

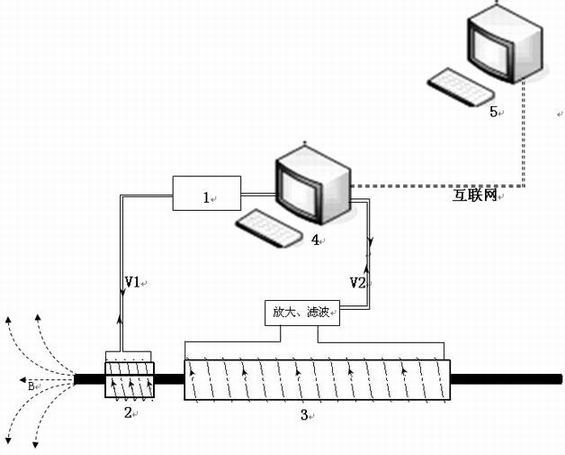

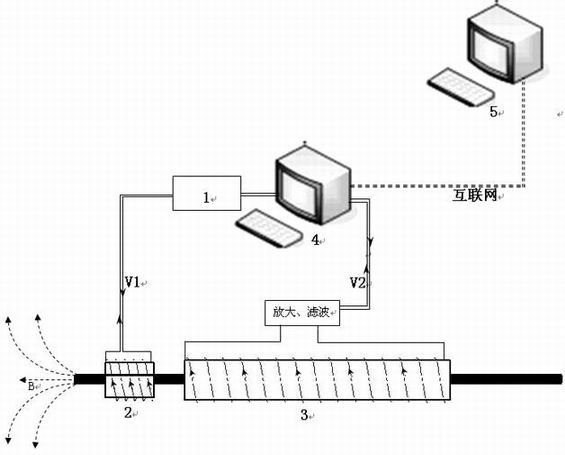

[0009] A remote online calibration method for a magnetic sensor, comprising the steps of:

[0010] (1) First install a calibration instrument on the magnetic sensor core at the calibration site, and the coil of the calibration instrument is connected to a sine wave circuit and the control computer at the calibration site. The calibration instrument of the present invention is to install and fix a supporting body on the magnetic core of the magnetic sensor, and an enameled wire coil is evenly wound on the supporting body, and a resistance is connected in series at one end of the coil, and the resistance value of the resistance is determined according to the size of the required magnetic field. There is an open-loop shield. When in use, by applying an AC voltage signal of a certain frequency and a certain intensity, a magnetic field of a corresponding intensity and a corresponding frequency is generated in the coil. The magnetic sensor senses the magnetic field signal to genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com