Coloring light-sensitive resin composition, and a colorful optical filter and a liquid crystal display device manufactured by using the coloring light-sensitive resin composition

A technology of photosensitive resin and composition, applied in optical filters, photosensitive materials for optomechanical equipment, optics, etc., can solve problems such as poor surface, achieve good transparency, high sensitivity characteristics, improve productivity and income Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

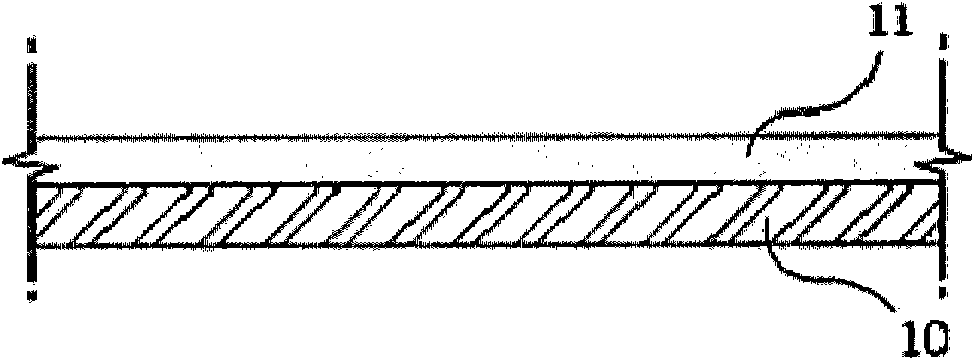

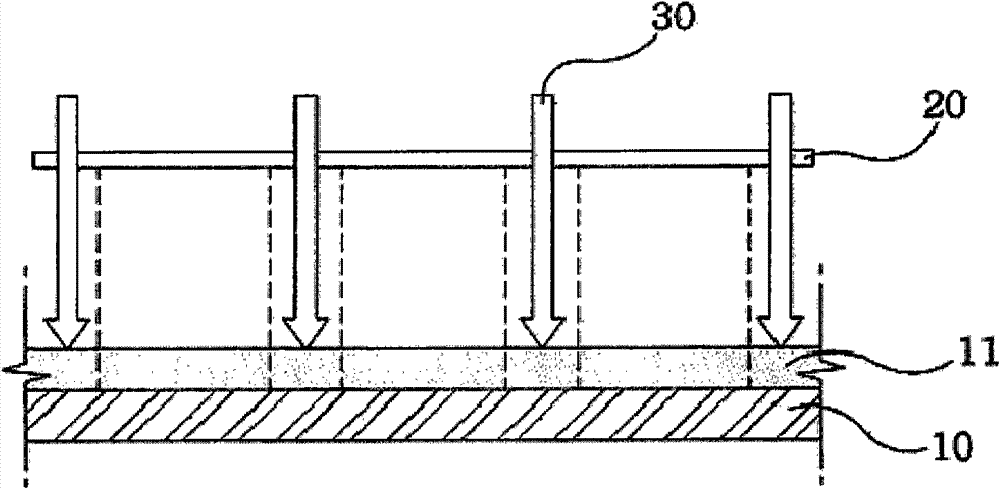

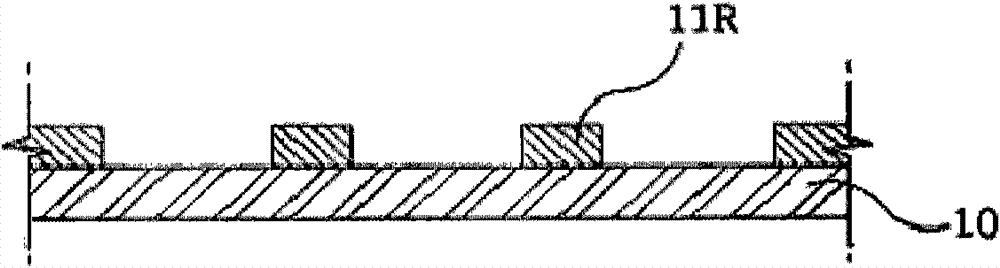

[0137] Figure 1a-Figure 1c is a schematic diagram of a process for manufacturing a color filter using a colored photosensitive resin composition according to the first embodiment of the present invention.

[0138] The present invention is to coat the colored photosensitive resin composition involved in the present invention on the substrate, such as Figure 1a As shown, a colored layer ( 11 ) made of a colored photosensitive resin composition is formed on the upper portion of the substrate ( 10 ). For this process, for example, a colored photosensitive resin composition diluted with a solvent is applied to the upper part of the substrate by a coating method such as rotation, slitting and rotation, slitting, flattening, spraying, and inkjet, and the solvent, etc. are volatilized. Sexual components are volatile. In this way, the colored layer (11) made of the colored photosensitive resin composition is formed, and the formed colored layer is composed of solid components of th...

Synthetic example 1

[0147] Synthesis Example 1

[0148] PolyFox TM 83.8 parts by weight of PF-656 (OMNOVA), 15 parts by weight of acryl isocyanate AOI (Showa Denko), 0.8 parts by weight of dibutyltin laurate as a catalyst, and 0.4 parts by weight of methoxyhydroquinone as a stabilizer 100 parts by weight of propylene glycol methyl ether acetate as a diluent was dropped into three 500ml reactors, and stirred in a reaction device with a condenser, a mechanical stirrer, a thermometer and a heating cover. Initially, the temperature rises to 60°C through self-heating, and after the temperature drops slowly, the temperature is maintained at 70°C for 5 hours, and the FT-IR is measured. When the characteristic peak of the isocyanate is 2260cm -1 The reaction ends when it disappears completely. The overall reaction formula is as follows

[0149] Reaction 1

[0150]

Synthetic example 2

[0151] Synthesis Example 2

[0152] 83.8 parts by weight of fluorine-based polyol Fluorolink E10-H (Solvay), 15 parts by weight of acryl isocyanate AOI (Showa Denko), 0.8 parts of dibutyltinyl laurate as a catalyst, and methoxyhydroquinone as a stabilizer 0.4 parts, 100 parts of propylene glycol methyl ether acetate as a diluent, were dropped into a three-port 500ml reactor, and stirred in a reaction device having a condenser, a mechanical stirrer, a thermometer and a heating cover. Initially, the temperature rises to 60°C through self-heating, and after the temperature drops slowly, the temperature is maintained at 70°C for 5 hours, and the FT-IR is measured. When the characteristic peak of isocyanate is 2260cm -1 The reaction ends when it disappears completely. The overall reaction formula is as following reaction formula 2.

[0153]

[0154]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com