Circulating pressurized nitrogenization stirring method for blending edible blend oil

A cyclic pressurization and stirring technology, which is applied in the production/processing of edible oil/fat, edible oil/fat, and the preservation of edible oil/fat finished products, etc., can solve the problem of poor quality stability, inability to effectively isolate air, and oil oxidation. rancidity and other problems, to achieve the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

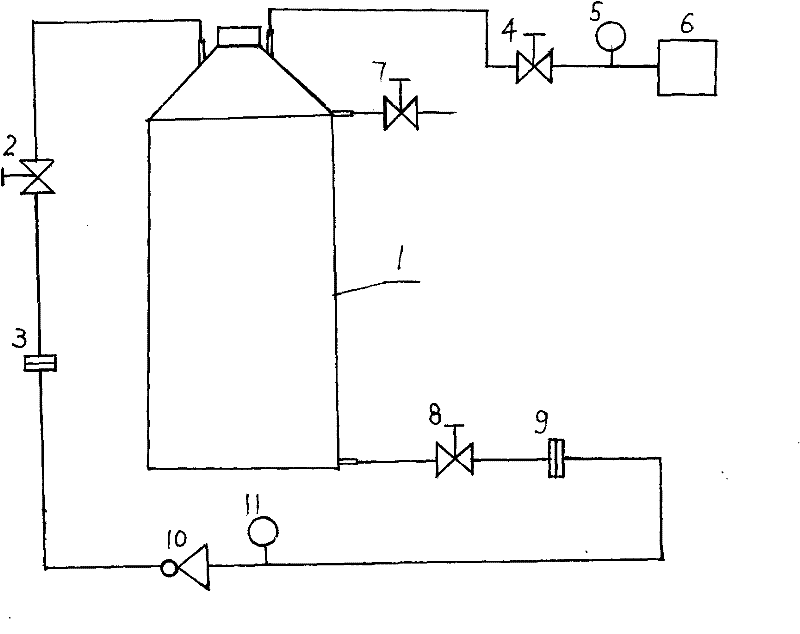

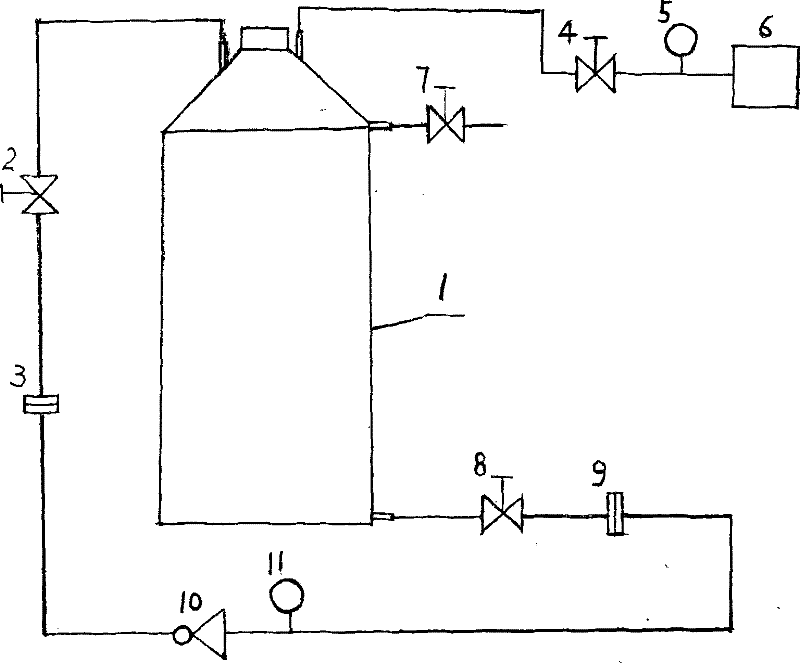

[0020] Such as figure 1 As shown, the present invention adopts a sealed oil transfer tank 1, an oil inlet and an air inlet are arranged on the top of the tank, and an inlet regulating valve 2 and an inlet movable joint 3 connected with a flexible pipe are installed on the inlet pipe connected to the oil inlet. The intake pipe connected to the intake port is equipped with an intake control valve 4, an intake pressure gauge 5 and a nitrogen generator 6 (model: CA-T-20), and an exhaust port and an exhaust valve 7 are located at the bottom of the tank top. There is an oil outlet at the lower part of the body, and the outlet pipe connected to the oil outlet is equipped with an outlet regulating valve 8 and an outlet movable joint 9 connected with a hose, and a gear pressure pump 10 is matched with the oil transfer tank 1, and the outlet pipe of the gear pressure pump Outlet pressure gauge 11 is housed on.

[0021] The production technology that the present invention adopts is as f...

Embodiment 2

[0034] This embodiment is basically the same as Example 1, except that the outlet pressure of the gear pressure pump is 0.6Mpa in the process of filling nitrogen and stirring.

Embodiment 3

[0036] This embodiment is basically the same as Example 1, except that the outlet pressure of the gear pressure pump is 0.1Mpa in the process of filling nitrogen and stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com