Parallel four-degree-of-freedom intersection line welding robot

A welding robot and degree-of-freedom technology, applied in the field of robots, can solve problems such as unintuitiveness and inconvenience, achieve good economic performance, and avoid the effect of wire winding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

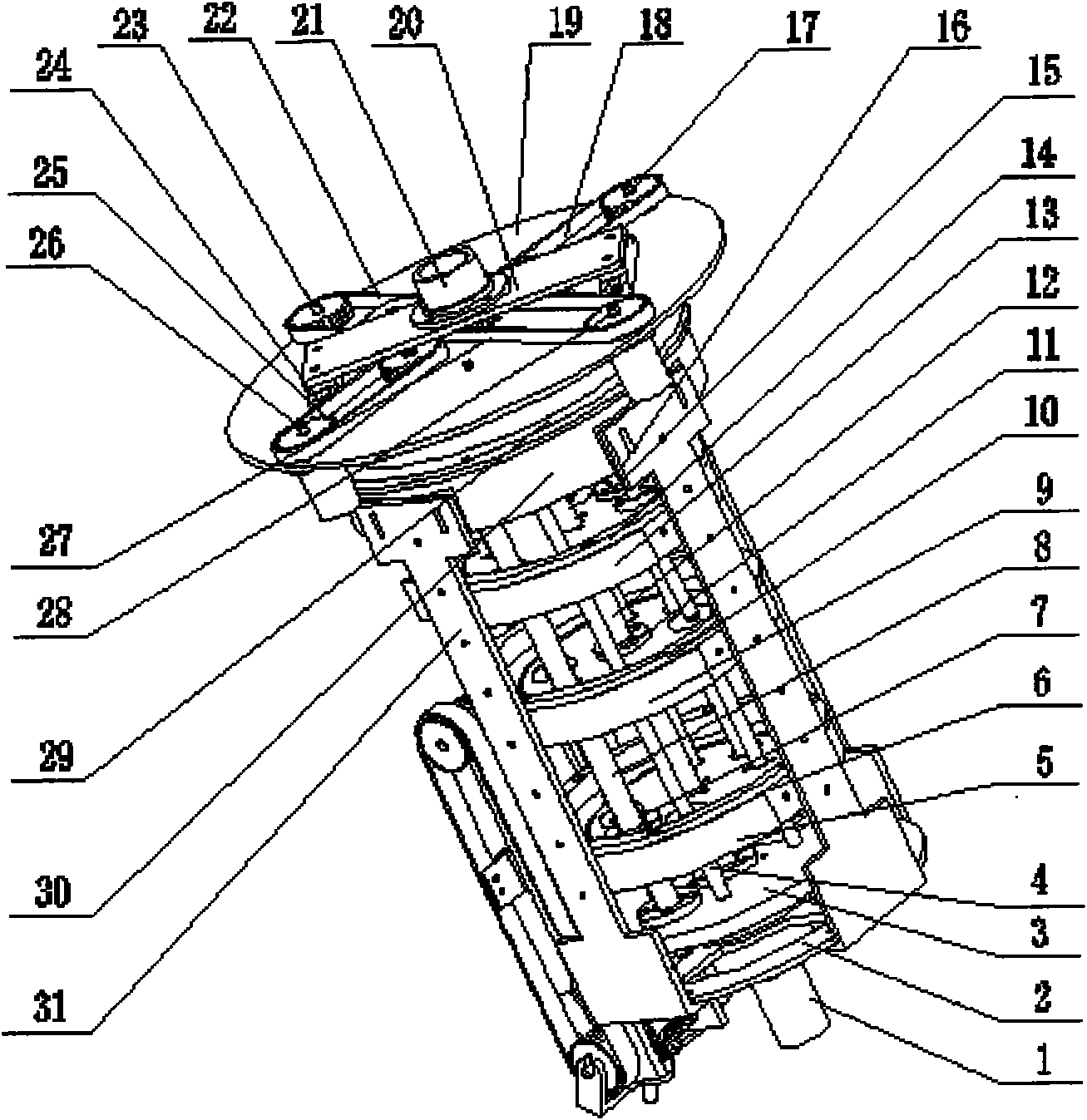

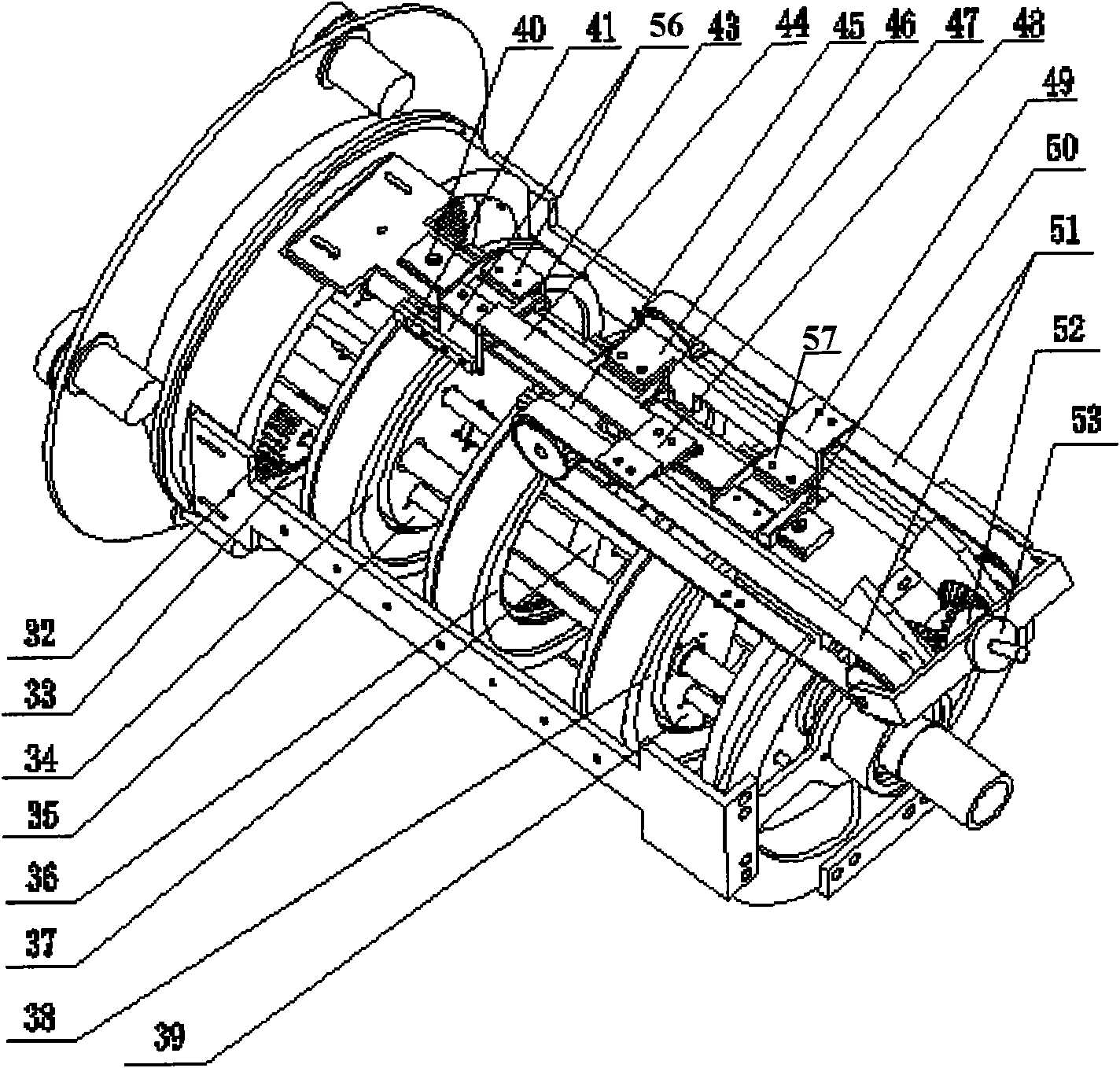

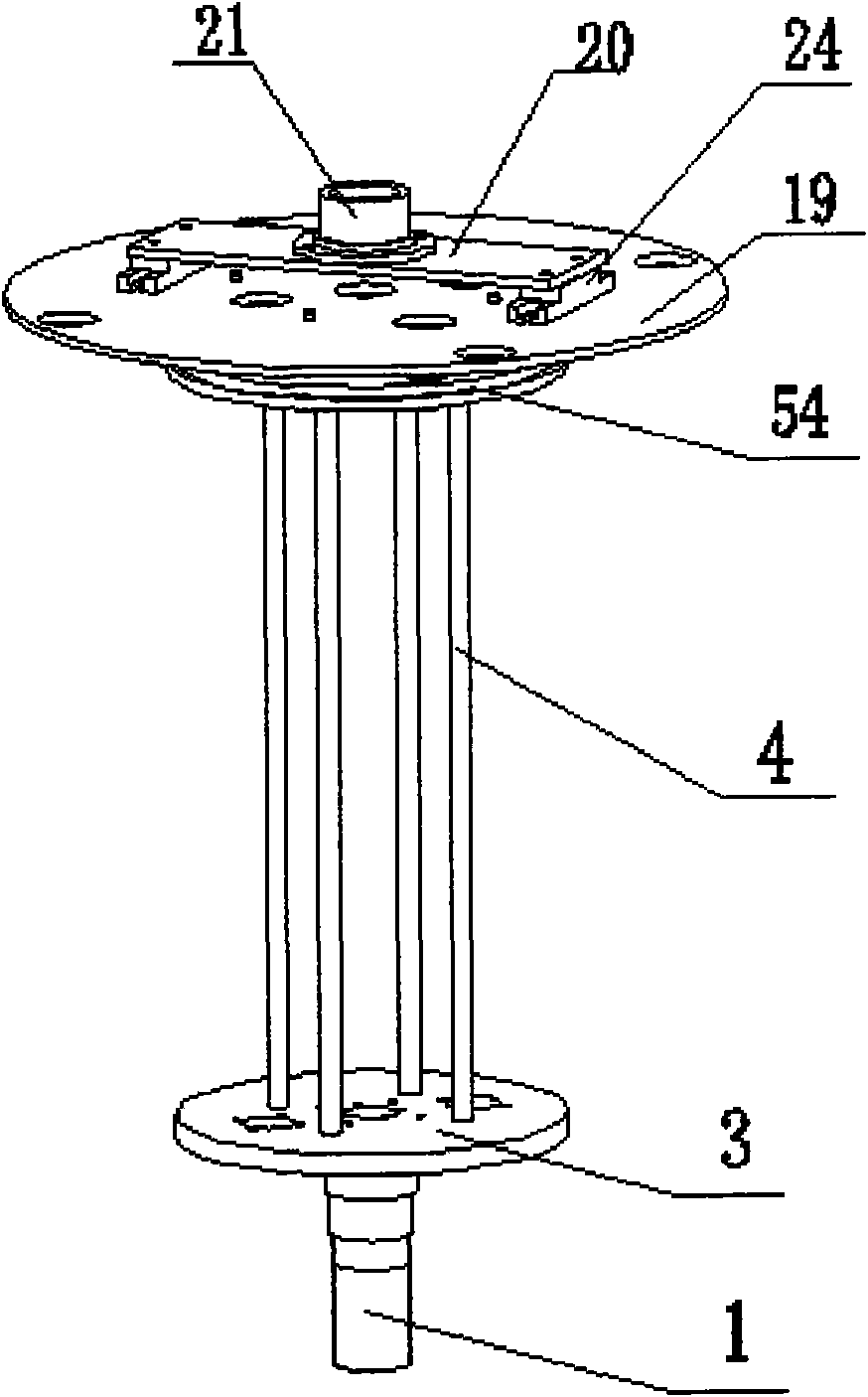

[0025] Attached below Figure 1-Figure 7 The present invention is further described:

[0026] According to the shape of the intersecting line, it can be seen that four movements are required to complete the intersecting line weld, so the present invention has four degrees of freedom, namely: welding torch rotation, welding torch lifting, welding torch pitch, welding torch deflection, wherein rotation and lifting are position adjustments, Pitch and yaw are attitude adjustments.

[0027] The principle is: the four degrees of freedom are driven by four stepping motors I-IV, and the motors I-IV are all installed on the frame, and the frame is installed on the workpiece through the frame, so the motor is fixed relative to the workpiece. The motor 1 drives the gear and meshes with the internal gear. The internal gear is installed inside the rotating cylinder, and the rotating cylinder rotates around the frame to realize the degree of freedom of rotation. Motor II drives the lead s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com