Method for producing bark mixed medium-density fiber plate

A production method and technology of bark fiber, applied in the field of bark mixed medium density fiberboard, can solve the problems of hydrolytic denaturation, inapplicability of separating bark fiber, and low utilization rate of bark, so as to reduce sewage discharge and improve comprehensive utilization rate , the effect of reducing the amount of glue used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

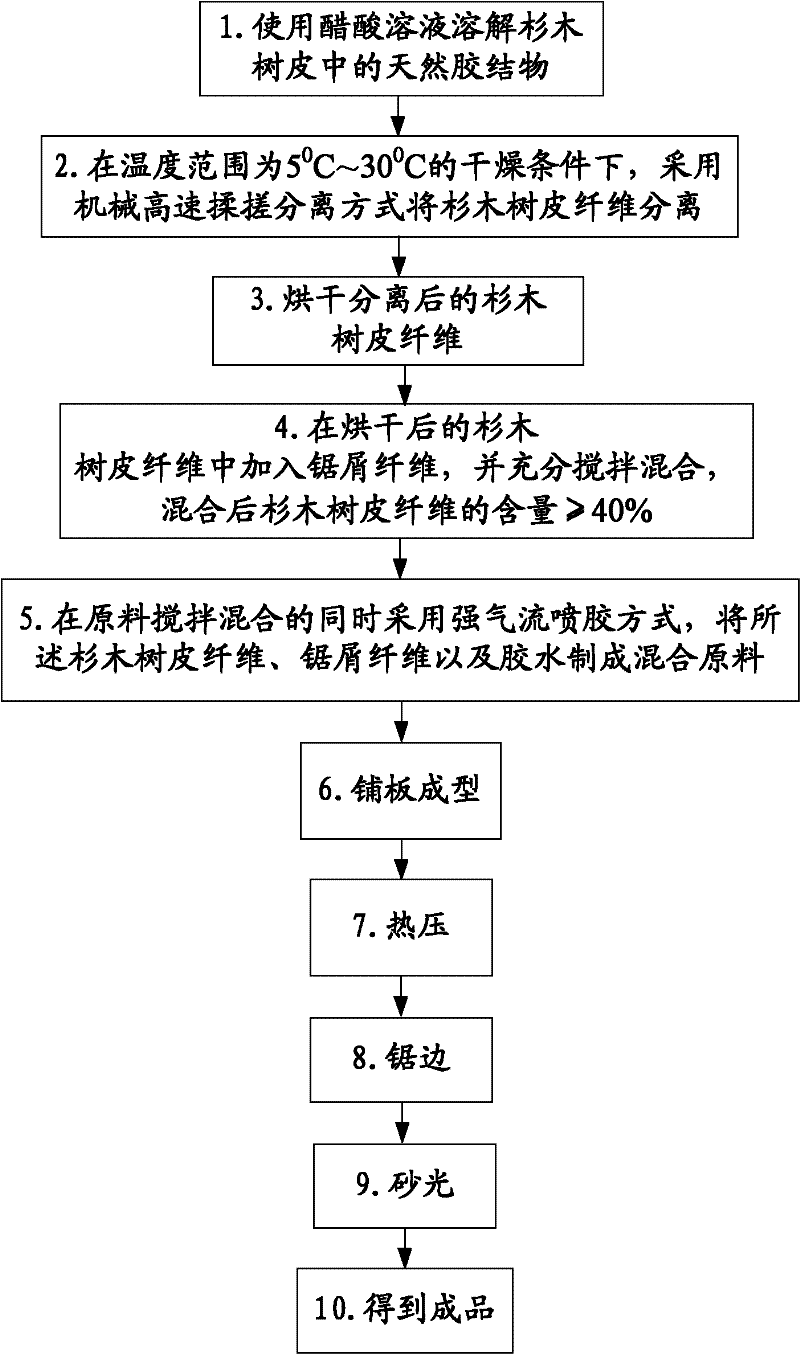

[0027] see figure 1 , is the first embodiment of the production method of bark mixed medium density fiberboard of the present invention, the production method of this bark mixed medium density fiberboard comprises the following steps:

[0028] 1. First use 10% acetic acid solution to dissolve the natural cement in the bark. After the natural cement in the bark is removed, the bark fibers can be separated more easily.

[0029] 2. Since the fir bark fiber components have the characteristics of low lateral bonding strength, the bark fibers can be separated by mechanical high-speed rubbing and separation under normal temperature drying conditions with a temperature range of 5°C to 30°C.

[0030] 3. Drying the separated bark fibers subsequently, so that the moisture content of the dried bark fibers is controlled within the range of 12% to 15%.

[0031] 4. Add sawdust fibers to the dried bark fibers, stir and mix thoroughly, so that the mixed bark fiber content is ≥ 40%, and the sa...

no. 2 example

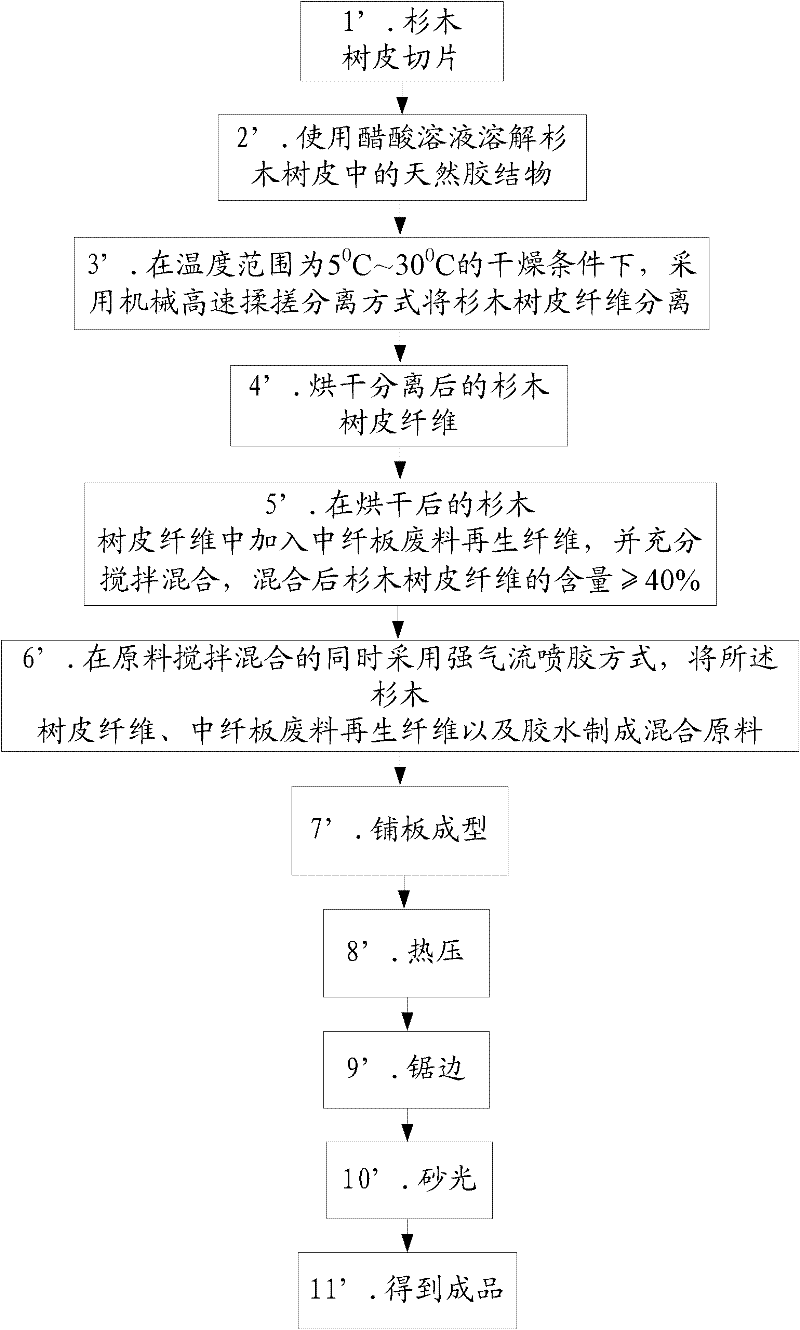

[0036] see figure 2 , is the second embodiment of the production method of bark mixed medium density fiberboard of the present invention, the production method of this bark mixed medium density fiberboard comprises the following steps:

[0037] 1'. First cut the bark into sheet bark of uniform specification, the natural thickness of the sheet bark is ≤ 1mm, the length is 0.5cm ~ 1cm, and the width is ≤ 3mm.

[0038] 2'. Use acetic acid solution with 10% acetic acid content to process and dissolve the natural cement in the flaky bark. After the natural cement in the flaky bark is removed, the bark fibers can be separated more easily.

[0039] 3'. Since the fir bark fiber components have the characteristics of low lateral bonding strength, the bark fibers can be separated by mechanical high-speed rubbing and separation under normal temperature drying conditions with a temperature range of 5°C to 30°C.

[0040] 4'. drying the bark fiber after separation subsequently, the moistu...

no. 3 example

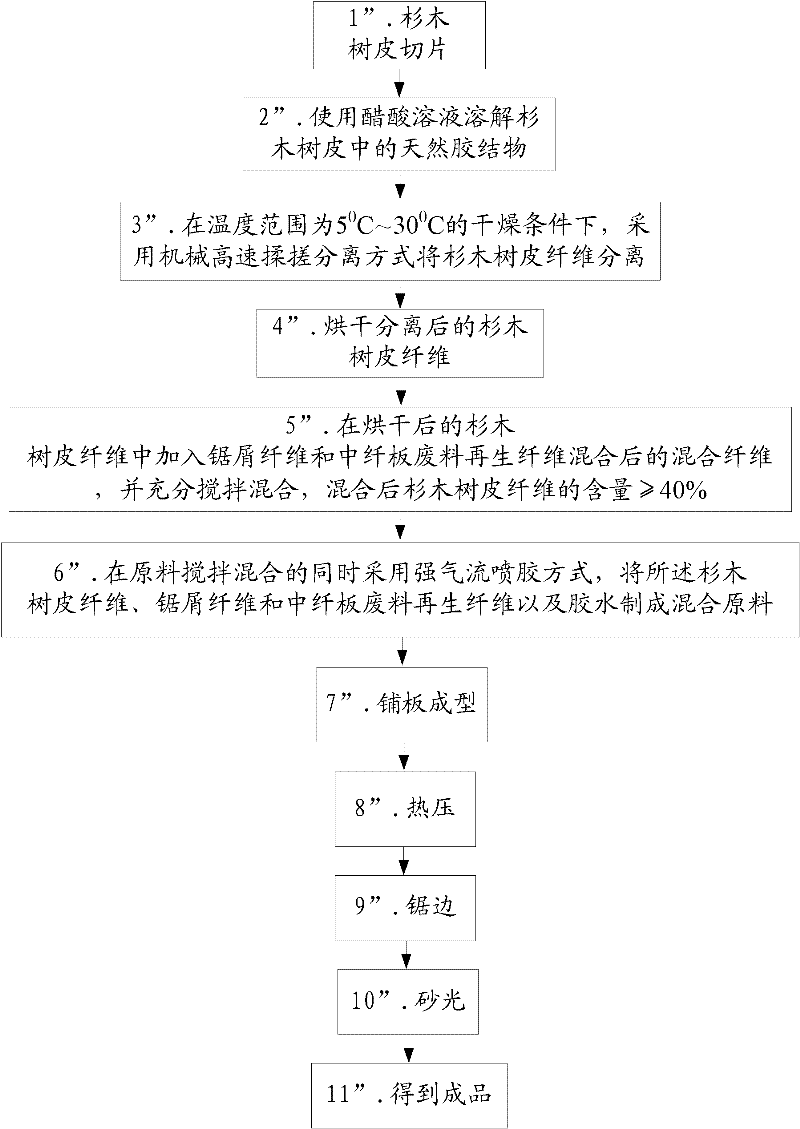

[0046] see image 3 , is the third embodiment of the production method of bark mixed medium density fiberboard of the present invention, the production method of this bark mixed medium density fiberboard comprises the following steps:

[0047] 1". Firstly cut the bark into sheet-like bark with uniform specifications, the natural thickness of the sheet-like bark is ≤1mm, the length is 0.5cm-1cm, and the width is ≤3mm.

[0048] 2". Use an acetic acid solution with an acetic acid content of 10% to dissolve the natural cement in the flaky bark. After removing the natural cement in the flaky bark, the bark fibers can be separated more easily.

[0049] 3". Since the fir bark fiber components have the characteristics of low lateral bonding strength, the bark fibers are separated by mechanical high-speed rubbing and separation under normal temperature drying conditions with a temperature range of 5°C to 30°C.

[0050] 4". Then dry the separated bark fibers, so that the moisture conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com