Depressed center flat car

A technology of flat cars and underframes, which is applied in the field of flat cars with concave bottoms. It can solve the problems of large transition angle of the bending part, unreasonable arrangement of bearing methods, and inability to arrange braking devices, etc., and achieves the effect of increasing headroom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

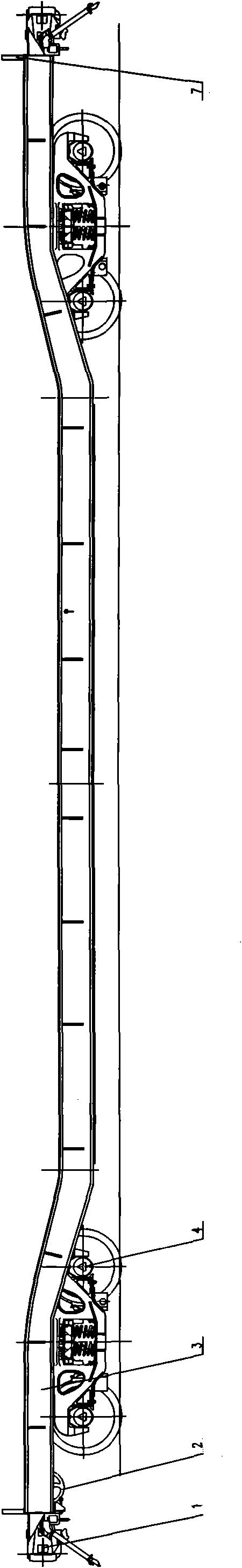

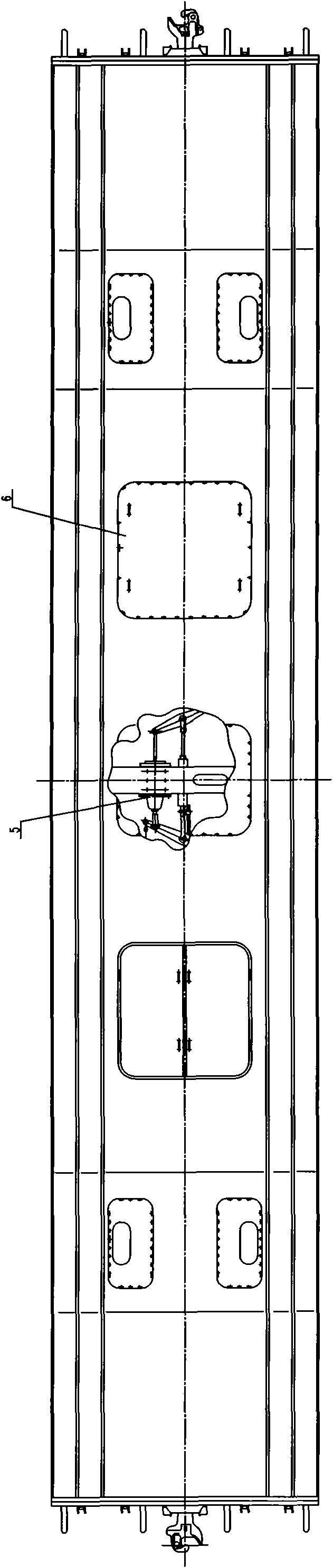

[0026] A flat car with a concave bottom, its composition includes: a concave bottom frame 3, the two ends of the concave bottom frame are connected to the coupler buffer device 1 and the end turning device 7, and a hand brake is installed on one end of the concave bottom frame Device 2, the two ends of the lower part of the concave underframe are connected to the bogie 4, the middle and lower part of the concave underframe is equipped with an air brake device 5, and the concave underframe is connected to the middle storage device 6. The coupler buffer device is installed at both ends of the concave underframe, which is used to connect with other railway wagons and transmit the longitudinal impact force; the hand brake device is installed at one end of the concave underframe to realize the human braking of the vehicle; the bogie is installed on the concave bottom The lower part of the frame end is used to transmit the vertical load and make the vehicle run on the track; the air ...

Embodiment 2

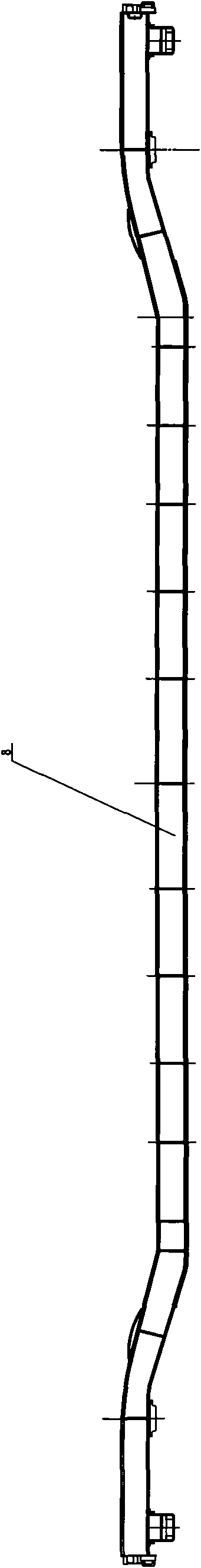

[0028] For the flat car with a concave bottom, the concave bottom frame includes two measuring beams 8, the side beams are a concave curved structure in the middle, and the two side beams are connected by a cross beam 9. The two ends of the side beam are vertically connected to the corbel 10, the corbel is connected to the bogie, the corbel is connected to the cross beam to the traction beam 11, and the traction beam is buffered to the coupler The device is connected, and the side beam is connected to the floor 12 on the cross beam. The side beam is the main bearing part of the concave chassis; the corbel is perpendicular to the side beam and welded on the side beam along the lateral direction of the car body, and is used to connect with the bogie; the traction beam is located at both ends of the concave chassis, and is welded with the cross beam and the corbel , used to install the coupler buffer device; the cross beam is arranged laterally along the car body to connect the s...

Embodiment 3

[0030] For the flat car with a concave bottom, the end turning device includes an end plate 13, the end plate is connected to a hinge 14, and the hinge is connected to a stopper 16 through a pin 15. The end plate and the hinge group are welded together; the hinge and the retaining iron are connected together with a pin, which is used to make the end plate rotate along the pin; the retaining iron is used to lock the end plate when it stands up; the bracket 18 is welded on On the concave chassis, it is used to support the end plate when the end plate is flush with the end force of the concave chassis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com