Method for preparing colorless hydrogenated rosin ester resin

A technology of hydrogenated rosin ester and manufacturing method, which is applied in the manufacture of rosin ester resin and deep processing of rosin, which can solve the problems of insufficient light color and high iodine value of the product, and achieve the effects of short hydrogenation time, low pressure and shortening the quality gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

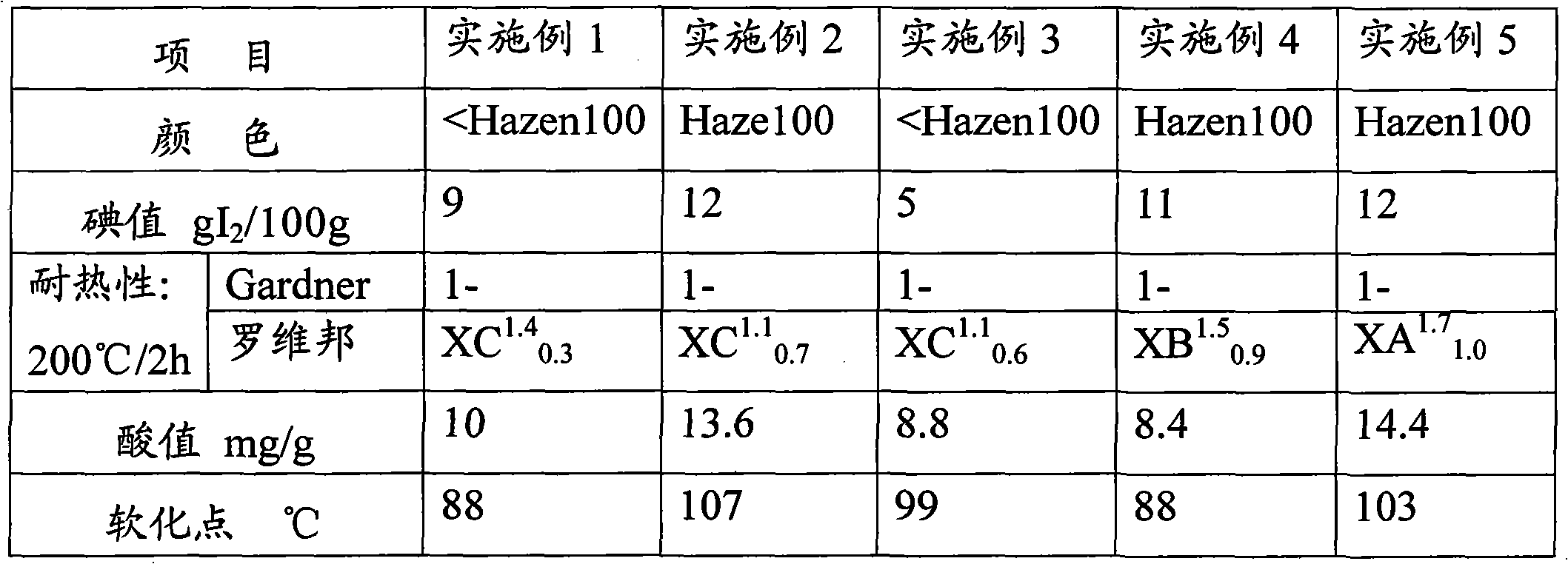

Examples

Embodiment 1

[0057] Example 1: A colorless hydrogenated rosin glyceride resin was prepared from refined rosin glyceride.

[0058] Solvent hydrogenation: mix the refined rosin glyceride and pinane in a certain proportion, dissolve at 80-120℃, and prepare a refined rosin glyceride solution with a concentration of 40-70%, with a flow rate of 200-800L / h The feed amount enters the hydrogenation system, and is preheated to 150-200°C and mixed with hydrogen, then enters a fixed bed reactor that has been equipped with a palladium loading rate of 2 to 5%, and an amount of 300-400kg palladium-carbon per batch Inside, the temperature of each reactor is controlled at 180-260°C, the temperature difference of each stage of the reactor is less than 10°C, showing an increasing distribution, the hydrogen pressure is between 5.0-15MPa, and the reaction time is 0.5-2 hours. The purity of the hydrogen is above 99.9%, and the separated hydrogen is recycled by the hydrogen circulation machine. When the carbon diox...

Embodiment 2

[0060] Example 2: Using refined rosin pentaerythritol ester to prepare colorless hydrogenated rosin pentaerythritol ester resin.

[0061] Solvent hydrogenation: add refined rosin pentaerythritol ester, add solvent pinane, dissolve at 80-120℃, prepare a refined rosin pentaerythritol ester solution with a concentration of 40-70%, and feed at a flow rate of 200-800L / h The amount enters the hydrogenation system, and is preheated to 150-200°C and mixed with hydrogen, then enters the fixed bed reactor that has been equipped with a palladium loading rate of 2-5% and a dosage of 300-400kg palladium-carbon per batch. Control the temperature of each reactor at 180-260°C, the temperature difference of each stage of the reactor is less than 10°C, showing an increasing distribution, the hydrogen pressure is between 5.0-15MPa, and the reaction time is 2-4 hours. The purity of the hydrogen is above 99.9%, and the separated hydrogen is recycled by the hydrogen circulation machine. When the carbo...

Embodiment 3

[0063] Example 3: Using refined disproportionated glyceryl rosin to prepare colorless hydrogenated rosin glyceride.

[0064] Solvent hydrogenation: add the refined disproportionated rosin glyceride and the solvent pinane to the melting pot, melt at 80-120℃, and prepare a refined disproportionated rosin glyceride solution with a concentration of 40-70% at a flow rate of 200- The feed rate of 800L / h enters the hydrogenation system, and it is preheated to 150-200℃ and mixed with hydrogen, and then enters the palladium loading rate of 2-5%, and the dosage is 300-400kg palladium-carbon per batch. In the fixed bed reactor, the temperature of each reactor is controlled at 180-260°C, the temperature difference of each stage of the reactor is less than 10°C, in an increasing distribution, the hydrogen pressure is between 5.0-15MPa, and the reaction time is 0.5-2 hours. The purity of the hydrogen is above 99.9%, and the separated hydrogen is recycled by the hydrogen circulation machine. Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com