Economic biphase stainless steel with high mechanical property and superior corrosion resistance

A duplex stainless steel and corrosion-resistant technology, which is applied in the field of typical austenitic stainless steel 304 and 316L alternative materials, can solve the problems of difficult realization, low strength performance, and fluctuation of alloy cost and price, and achieve low carbon content and stable price fluctuation. Sensitive, more economical and stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] 1. Implement the composition and process of steel

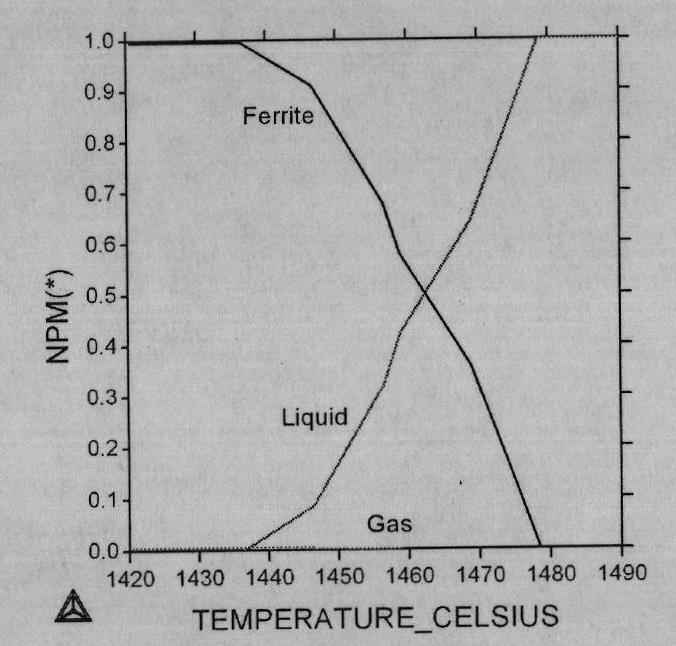

[0020] Proportioning is carried out according to the composition range of the economical duplex stainless steel of the present invention, and the vacuum induction furnace method is used for smelting to obtain the chemical composition (weight percentage) of the steel shown in Table 1. Casting was carried out according to the conditions in Table 1. After casting, water spray cooling was carried out in the temperature range from 1000°C to 500°C. There was no σ phase precipitation in the microstructure, and no cracks appeared on the slab surface, and high-quality cast slabs could be obtained.

[0021] Chemical composition and pouring temperature (weight percent, %) of table 1 invention stainless steel

[0022]

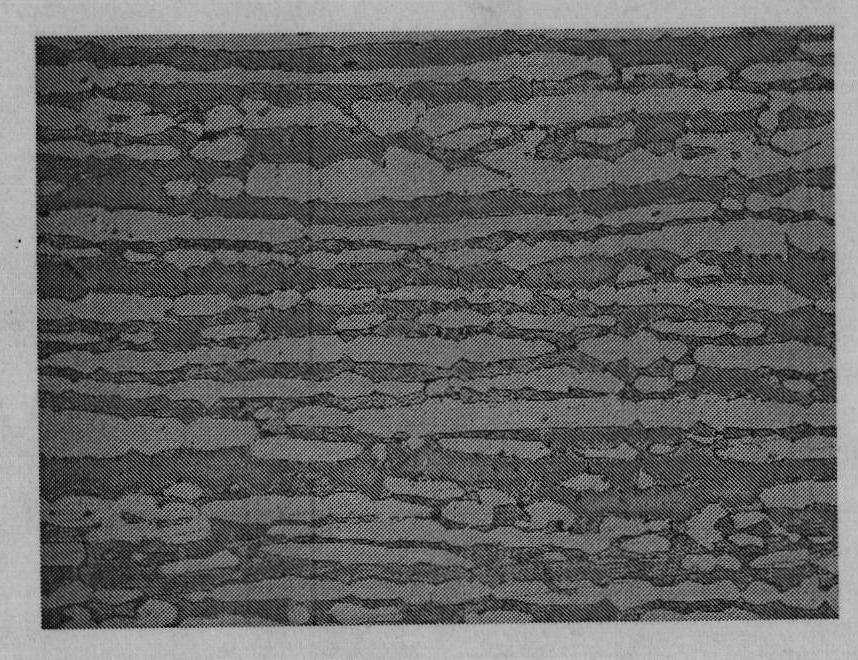

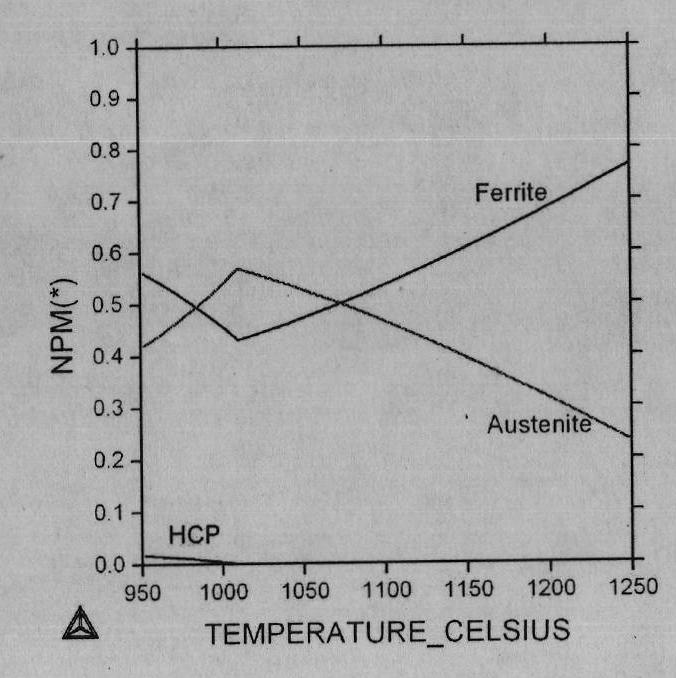

[0023] The slab was subjected to soaking treatment at 1250°C for 3 hours, and hot-rolled into hot-rolled sheets with a thickness of 6mm, 10mm and 16mm through multiple passes. The final rolling temperature was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ultimate tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com