Construction machine, in particular paver or movable feeder

A technology of construction machinery and building materials, applied in the direction of construction, roads, roads, etc., can solve problems such as uneven surface of new roads, truck drivers stepping on the brakes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

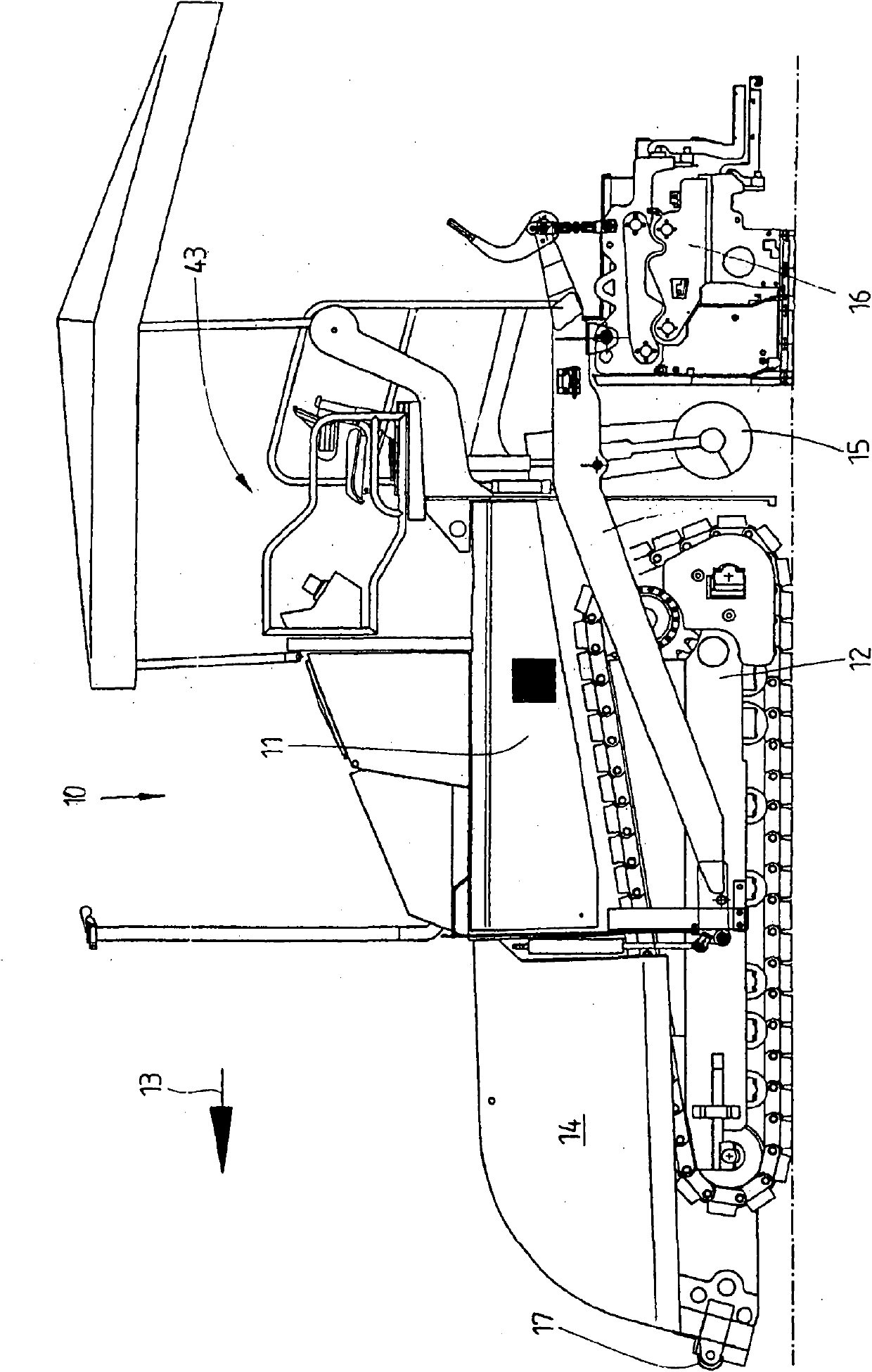

[0025] figure 1 A paving machine 10 schematically shown in FIG. 2 is used to create a road surface. In this respect, they can be any type of road surface.

[0026] Paving machine 10 is constructed to be self-propelled. For this purpose, it has a central drive unit 11 which has, for example, an internal combustion engine including a hydraulic pump for supplying the hydraulic motor and optionally a generator for generating energy for the electric drive.

[0027] Furthermore, the road paver 10 has a travel mechanism 12 which, in the illustrated embodiment, is constructed as a track gear laying mechanism. However, the carriage 12 of the paving machine can also be a wheeled carriage. The travel mechanism 12 is driven by a drive unit so that the road paver 10 can be moved forward in the production direction 13 .

[0028] Viewed in the production direction 13 , the storage bin 14 , which is configured in the form of a trough or hollow, is arranged in front of the drive unit 11 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com