Housing of large-scale liquefied natural gas storage tank and construction method thereof

A technology of liquefied natural gas and construction method, which is applied in the field of large-scale liquefied natural gas storage tank shells, can solve the problems that the structure impermeability cannot be fully guaranteed, and the shell construction is complicated, and achieves the effects of beautiful appearance and good seismic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

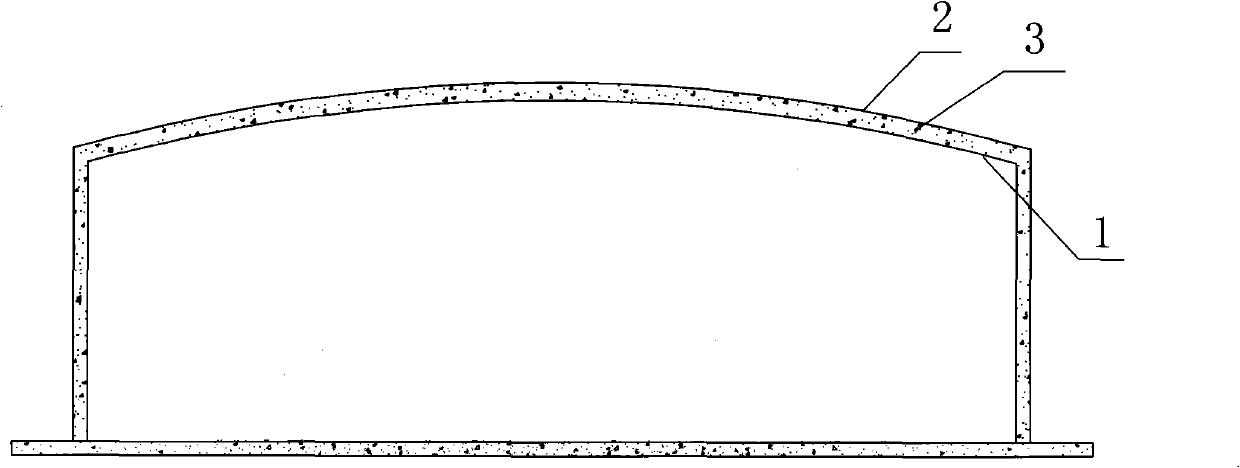

[0046] Such as figure 1 As shown, the shell of this large liquefied natural gas storage tank includes a tank wall, a tank roof, and a tank bottom. Both the tank wall and the tank roof are composed of an inner steel plate 1 and an outer steel plate 2 sandwiching a concrete layer 3, and the tank bottom is made of a reinforced concrete plate The composition is an LNG storage tank with a steel plate sandwich concrete structure. Concrete is poured in the annular cavity of the two-layer steel plate, so that the two materials of steel plate and concrete are fused together. When under pressure, the concrete in the annular cavity of the two-layer steel plates is in a three-way compression state due to the constraints of the steel plates. The three-way compression concrete not only improves the longitudinal compressive strength, but also improves the elastic modulus, and increases plasticity. For the inner and outer layers of steel plates, due to the close adhesion of concrete, it is ...

Embodiment 2

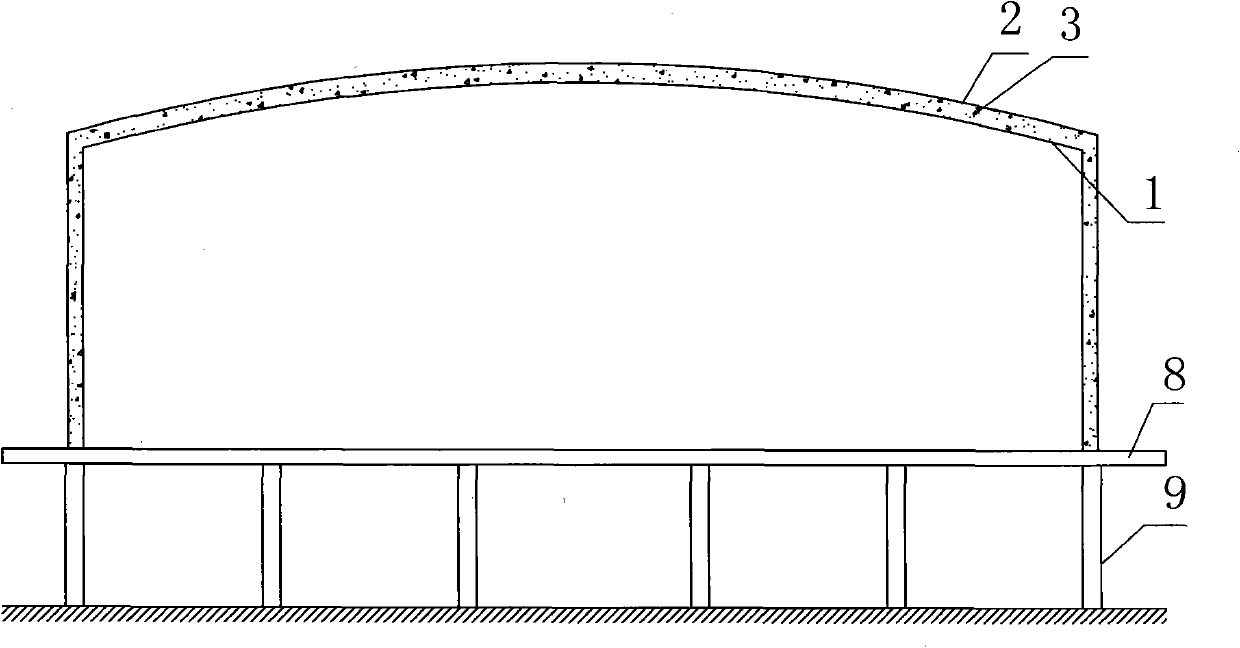

[0048] Such as figure 2 As shown, the shell of this large-scale liquefied natural gas storage tank includes a tank wall, a tank roof, and a tank bottom. The body is seated on the bottom frame 7, and the bottom frame 7 is composed of concrete beams and columns 9 and a concrete slab 8, and the tank wall is airtightly connected with the concrete slab 8.

Embodiment 3

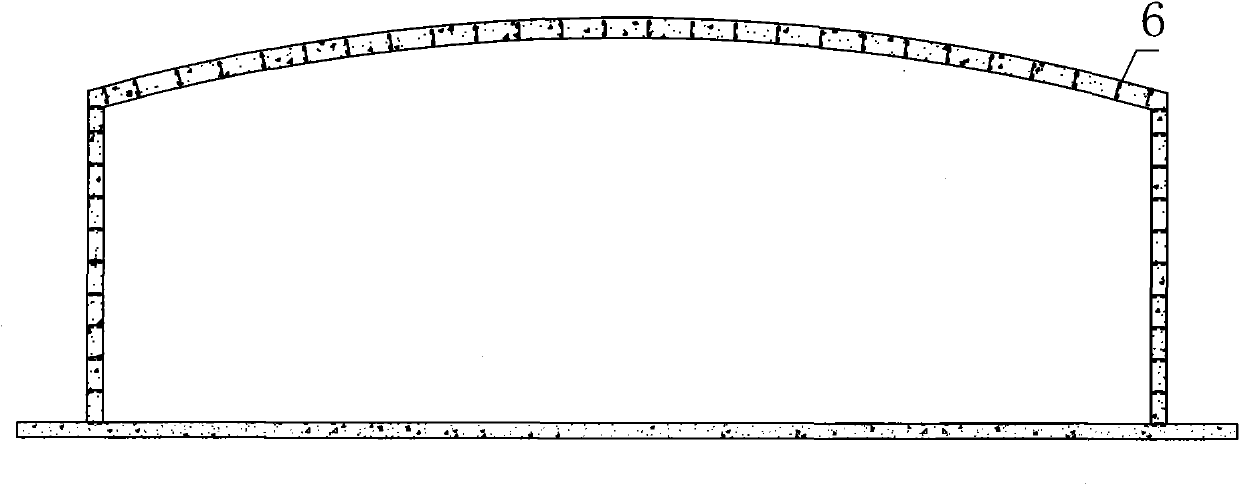

[0050] Such as image 3 As shown, the shell of this large liquefied natural gas storage tank includes a tank wall, a tank roof, and the tank wall, tank roof, and tank bottom are all composed of inner and outer layers of steel plates with a concrete layer 3 sandwiched between them, and the tank bottom is composed of reinforced concrete plates. In the concrete layer 3 at the tank wall, the steel bars 6 are welded side by side in the vertical direction, and in the concrete layer 3 at the tank top, the steel bars 6 are welded side by side in the arc direction. The welded steel bars 6 are HRB400 grade threaded steel bars.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com