Refrigerator handle assembling structure capable of realizing self-locking

An assembly structure and self-locking technology, which is applied to the spherical handle of the wing fan, the building lock, the wing fan handle, etc., can solve the problems of complicated procedures, improve the assembly efficiency, the assembly operation is simple and convenient, and the overall appearance effect is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

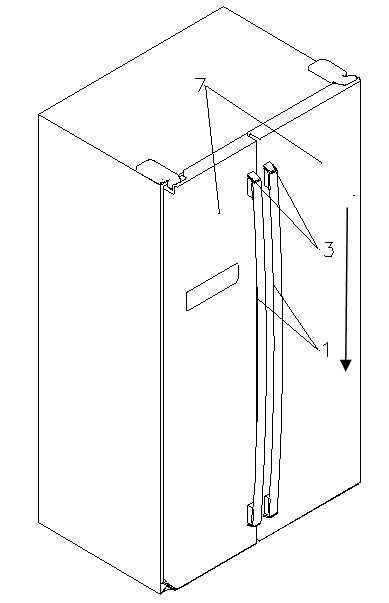

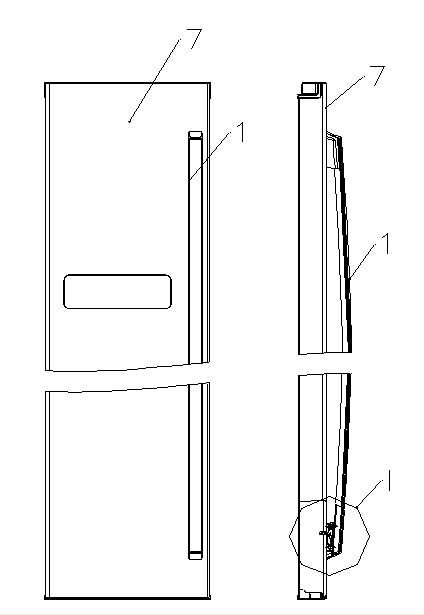

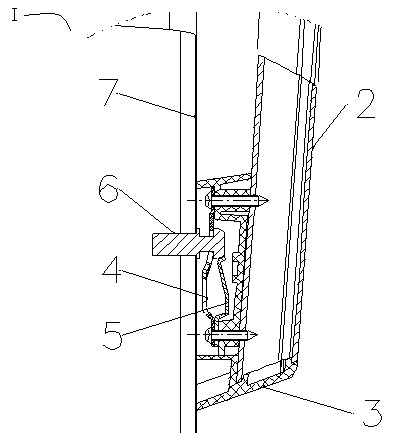

[0032] see figure 1 , figure 2 , image 3 , Figure 4 , the self-locking refrigerator handle assembly structure of the present invention includes a handle part 1, a handle 2, a handle seat 3, a handle connecting block 4, a self-locking elastic piece 5, a handle pillar 6 and a foam refrigerator door body 7. The handle support 6 is fixed on the refrigerator door 7, and the handle part 1 is buckled onto the handle support 6. The handle part 1 includes the handle 2 and the set handle seat 3 at the upper and lower ends of the handle 2, and the handle seat 3 is equipped with a handle connecting block 4 and the self-locking shrapnel 5, one end of the handle connection block 4, one end of the self-locking shrapnel 5 and one end of the handle base 3 are fixed on the handle 2 through the first connecting piece, the other end of the handle connection block 4 and the other end of the handle base 3 One end is fixed to the handle 2 through the second connecting piece; the other end ...

example 2

[0048] Such as Figure 7 Shown handle connection block 4 with Figure 8 The self-locking shrapnel 5 shown can also be designed as a whole, such as Figure 11 As shown, the material is made of spring steel, formed by a sheet metal mold, and integrated Figure 7 Shown handle connection block 4 with Figure 8 All the functions and assembly principles of the self-locking shrapnel 5 shown are completely the same as the first embodiment.

[0049] The refrigerator handle installation process is as follows:

[0050] After the refrigerator door body 7 foams, it will be as Figure 9 The handle support 6 shown is assembled on the door body 7 of the foaming refrigerator through an air batch, and the assembly effect diagram is shown in Figure 10 shown;

[0051] will be like Figure 5 Aluminum alloy handle 2 shown as well as Figure 11 The integral handle connection block shown is screwed to the Image 6 On the handle seat 3 shown, form the handle part 1, such as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com