Direct-buried type maintenance-free sleeve compensator

A sleeve compensator, maintenance-free technology, applied in the direction of damage protection, pipeline protection, pipeline protection through heat insulation, etc., can solve the problems that direct-buried pipeline compensation cannot be used, and the price of direct-buried corrugated compensators is high, so as to achieve good physical and chemical properties Stable performance, convenient on-site installation, and reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described in conjunction with accompanying drawing and embodiment:

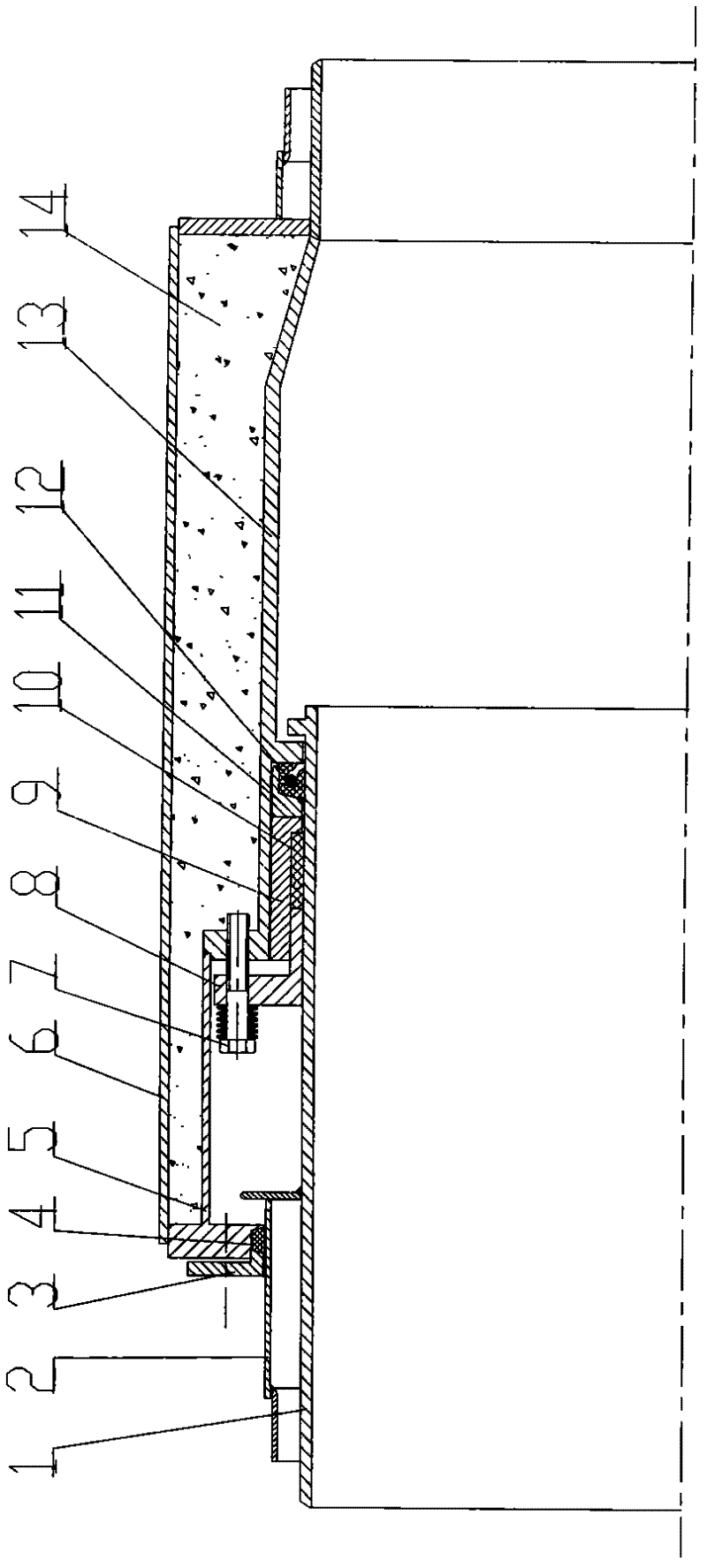

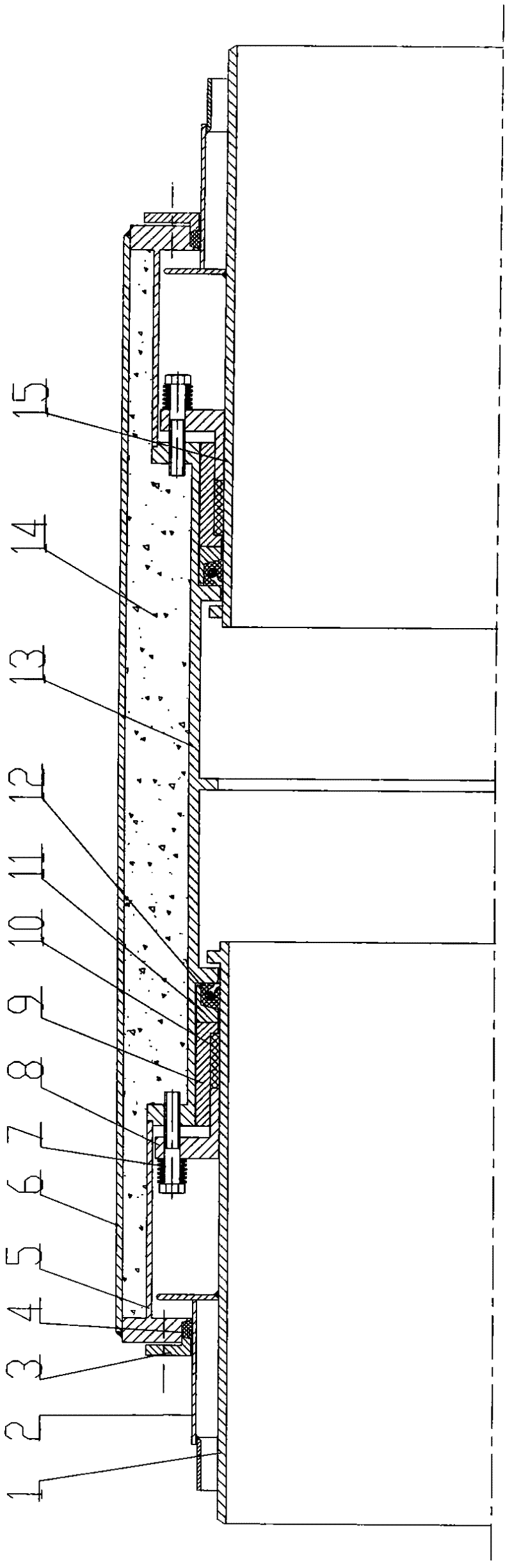

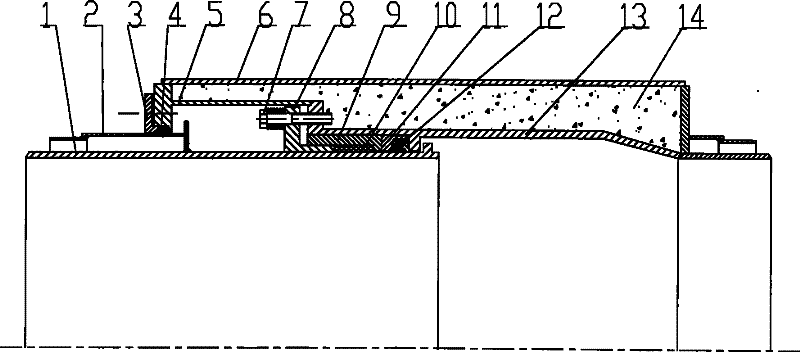

[0019] Such as figure 1 as shown, figure 1 It is a schematic diagram of the structure of a one-way direct buried maintenance-free sleeve compensator, which adopts a triple seal structure, with two seal structures set between the outer sleeve 13 and the end pipe 1, and one seal structure set between the end ring and the end pipe of the outer casing 6 1 between the sealing guide sleeves 2; the first heavy seal is composed of a combined sealing ring 12, an intermediate gland 9, and a floating pressure ring 11; the surface of the end pipe is sprayed with a corrosion-resistant and friction-reducing coating to reduce the combined sealing ring, packing packing and the surface of the end pipe; when working, as the medium pressure in the pipeline rises, under the joint action of the intermediate gland 9 and the floating pressure ring 11, the two lips of the combined sealing rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com