Static stiffness testing method for horizontal machining centre

A technology of static stiffness and test method, applied in the field of static stiffness test of horizontal machining center, can solve problems such as poor operability and unsatisfactory test results, and achieve the effect of high accuracy, high accuracy and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

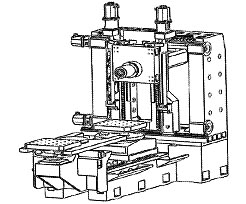

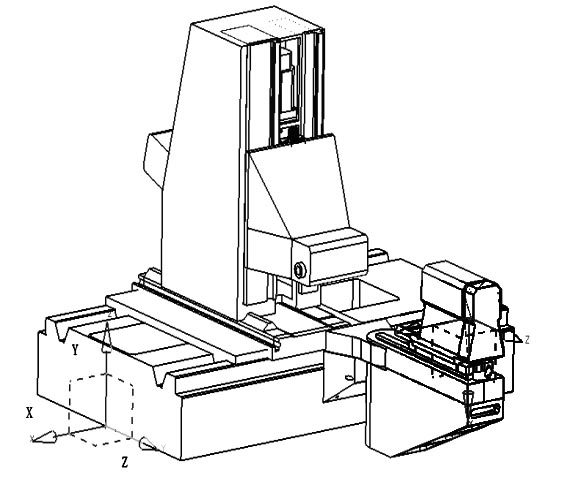

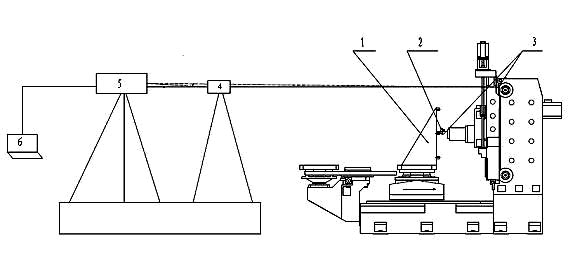

[0022] The static stiffness testing method of the horizontal machining center of the present invention:

[0023] (1) Apply load to the spindle head of the horizontal machining center through the loader 1, and simulate the working condition of the spindle bearing the cutting force when the machine tool is working. Set up three detection points on the left and right sides of the main shaft head and the upper part of the gantry frame (column) to detect the deformation and displacement values of the three places under force. The laser beam is emitted by the laser interferometer 5 and is divided into two paths of light after passing through the beam splitter 4. One path of light is reflected back after passing through the spectrometer, and the other path of light is returned by the reflector 3 installed at the detection point, and the laser beam at the las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com