Free drop test device

A drop test, free technology, applied in the direction of measuring device, impact test, machine/structural component test, etc., can solve difficult problems such as the shape of the shell, and achieve the effect of free fall and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings.

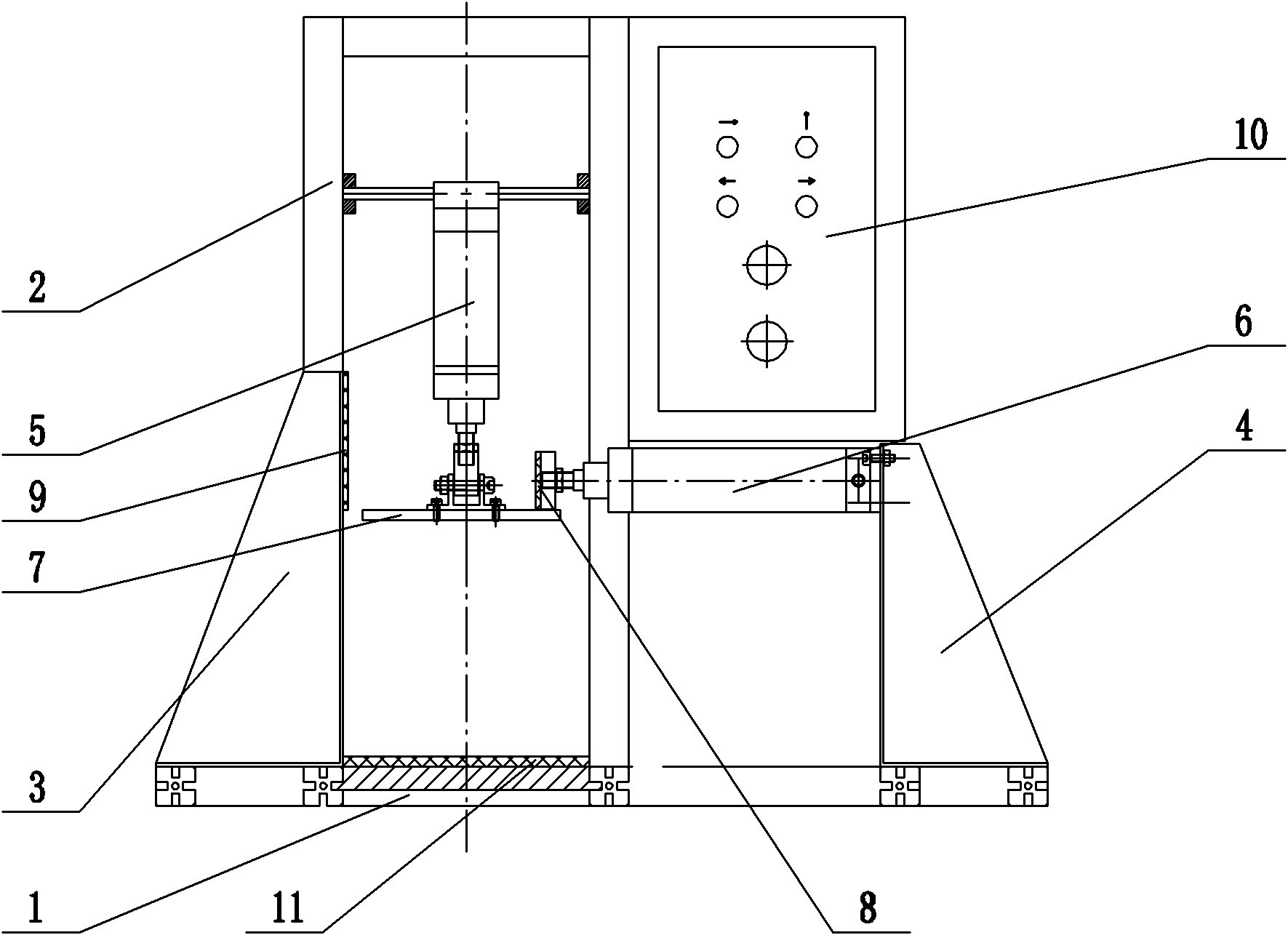

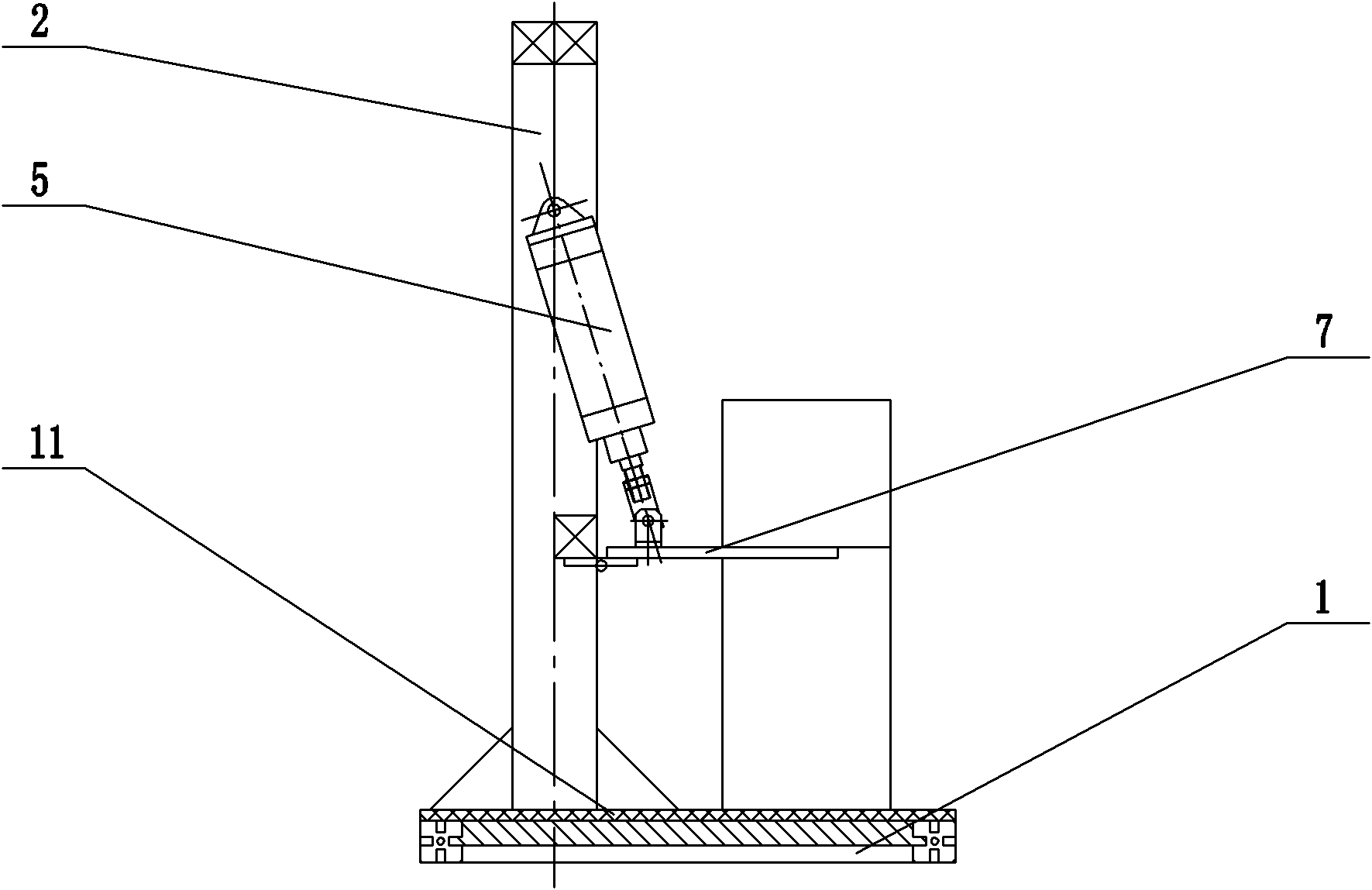

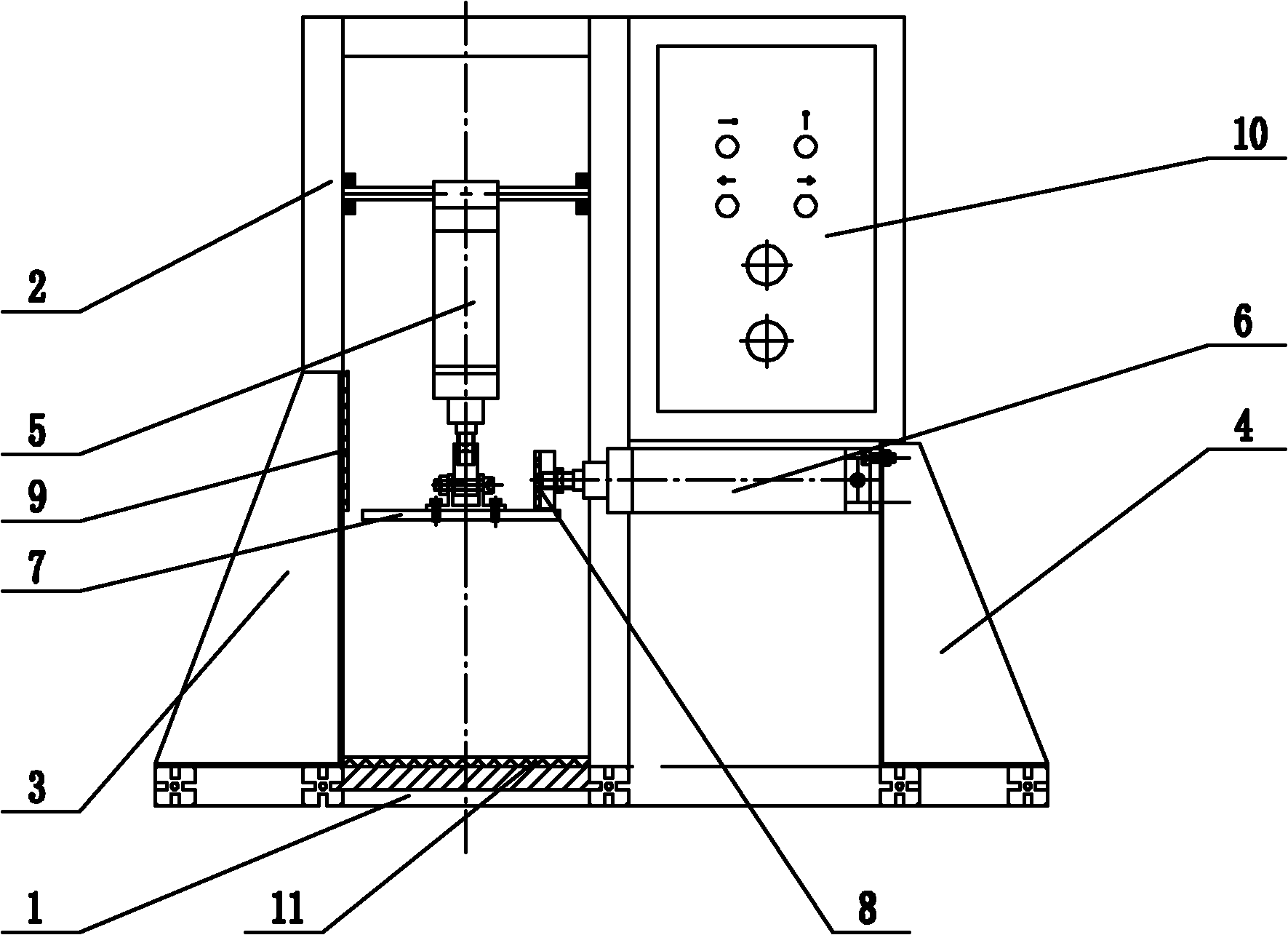

[0018] Such as Figure 1 ~ Figure 2 Shown: The free drop test device includes a base 1, a column 2, a left support seat 3, a right support seat 4, a first cylinder 5, a second cylinder 6, a support plate 7, a push rod chuck 8, a splint 9, and a control panel 10. Red pine board 11, etc.

[0019] The present invention adopts that a column 2 is set on the base 1, a left support seat 3 and a right support seat 4 are fixed on the base 1 on one side of the column 2, a first cylinder 5 is pivotally arranged on the column 2, and a first cylinder 5 is pivoted on the right support seat. 4 is provided with a second cylinder 6, and a splint 9 is provided on the left support plate 3. The piston rod of the first cylinder 5 is connected with the support plate 7, and the piston rod of the second cylinder 6 is connected with a push rod clamp Head 8, the splint 9 and the push rod chuck 8 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com