Method for inputting and comparing wiring harness data in automobile wiring harness detection equipment

A technology for testing equipment and automotive wiring harnesses, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., which can solve the problems of inflexible modification and configuration of application programs, problems in installation and contact of sample lines, and poor detection methods of wiring harnesses, etc. The cost of machine training, reliable work, and the effect of convenient program upgrades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

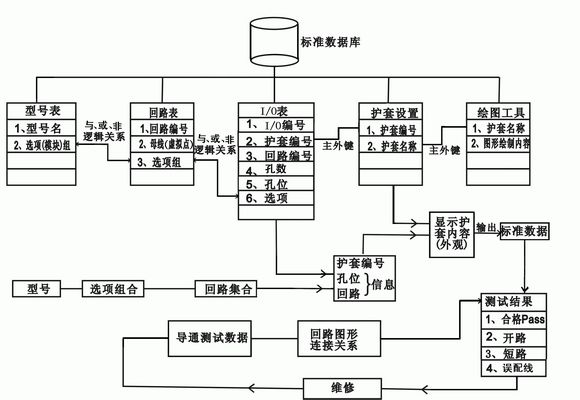

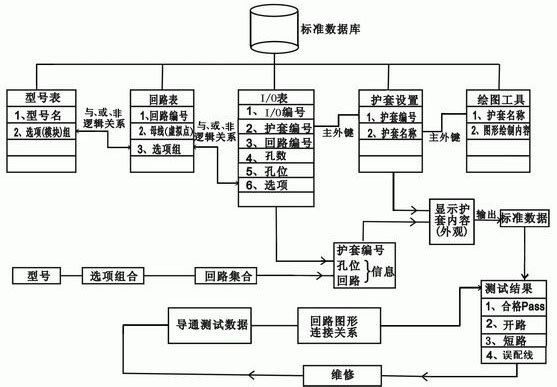

[0027] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation methods and features provided according to the present invention are described in detail as follows:

[0028] A method for inputting and comparing wire harness data in an automobile wire harness testing device, characterized in that the implementation steps are as follows:

[0029] The wire harness testing equipment of the invention mainly has two modules and one (two groups) of data comparison, the two modules are: editing of the circuit table (loop editor) module, acquisition of wire harness continuity test data (reading to the conduction table upper harness signal) module.

[0030] A data comparison is: the comparison between the measured wire harness signal data and the standard data.

[0031] Two major modules:

[0032] The circuit editing part involves more interface processing, so the software development with strong interface processing is adopted, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com