High-voltage motor stator coil end part splicing and shaping method

A technology for stator coils and high-voltage motors, applied in the direction of prefabricated windings embedded in motors, etc., can solve the problems of easily damaged end insulation, inconsistent end spacing, and different lifting angles, etc., to extend the mission of the motor, prolong the life of the motor, The effect of reducing the main size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

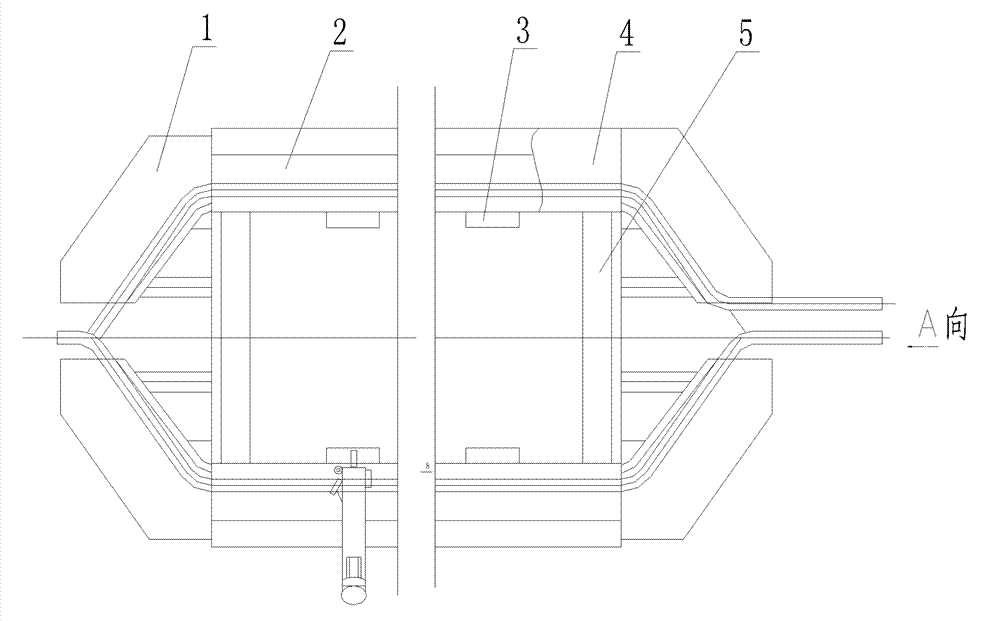

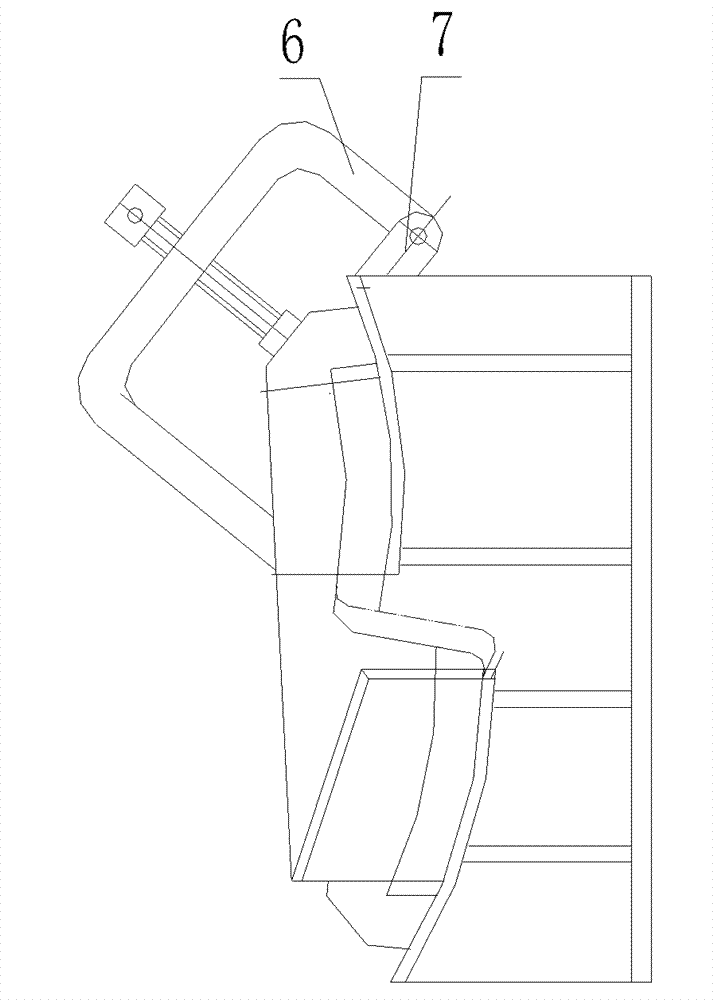

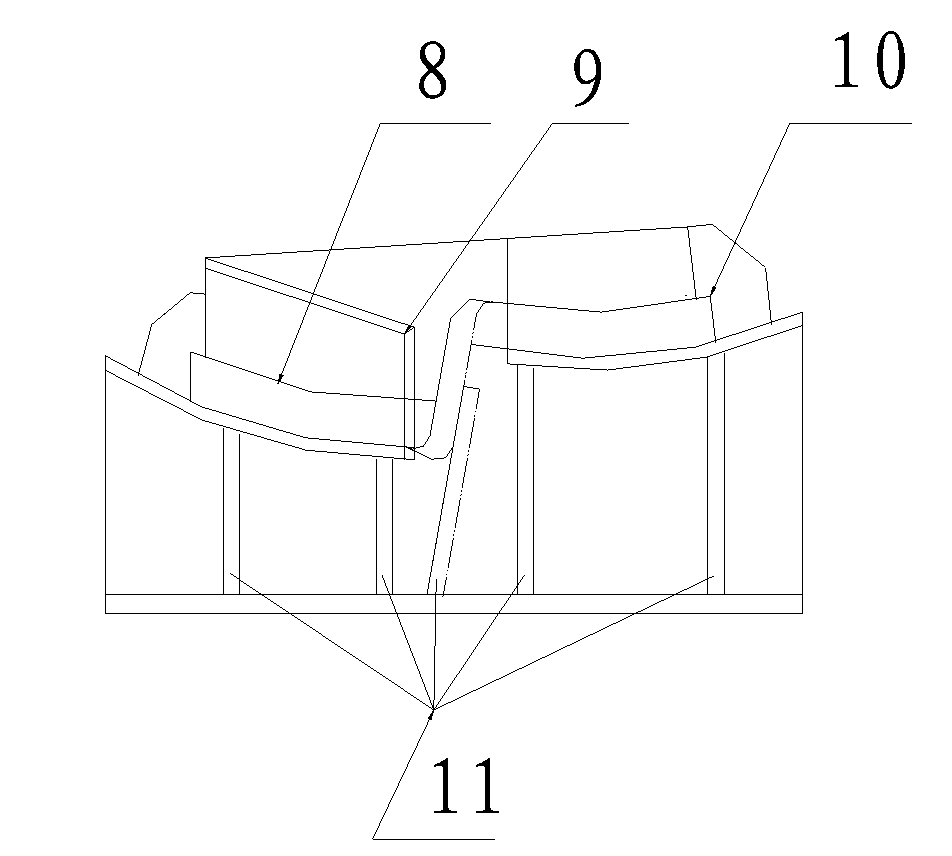

[0023] A method for splicing and shaping the stator coil ends of a high-voltage motor. The stator coil 8 is shaped by using a plastic shaping mold; , Kalan 6, end plate, side plate 9, end pressure iron 10, support plate 5; the process of making the plastic gelling mold, 1) first splicing the linear frame according to the angle model; 2) according to the size of the corner R at the end of the stator coil , as a garden column tooling, the side plate is heated and elastically bent on the garden column tooling to meet the R angle size of the end; 3) The end plate and the side plate are welded together to ensure that the 90° becomes the end iron; 4) Assembly and shaping When rubberizing the end tire of the mold, install the end support plate to avoid the dimensional error of the rising angle of the assembly nose. After the nose end of the first piece of coil is shaped according to the nose angle of the design drawing, the support plates 11 of different sizes at the nose end are wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com