Energy-saving hub motor

A wheel-hub motor and wheel-hub technology, which is applied in the direction of current collectors, electromechanical devices, electric vehicles, etc., can solve the problems of wasting energy and mechanical energy can not be used rationally, and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

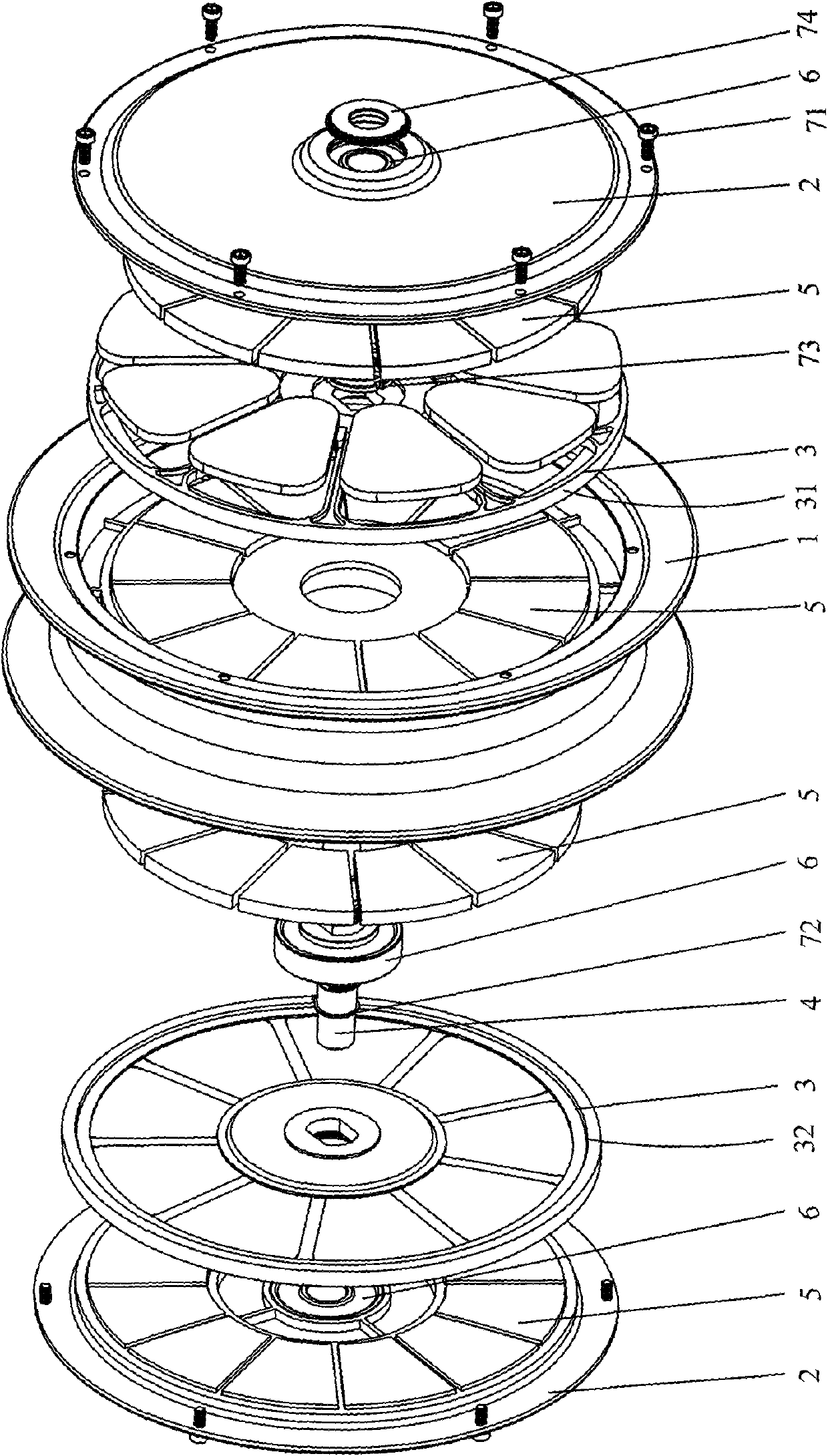

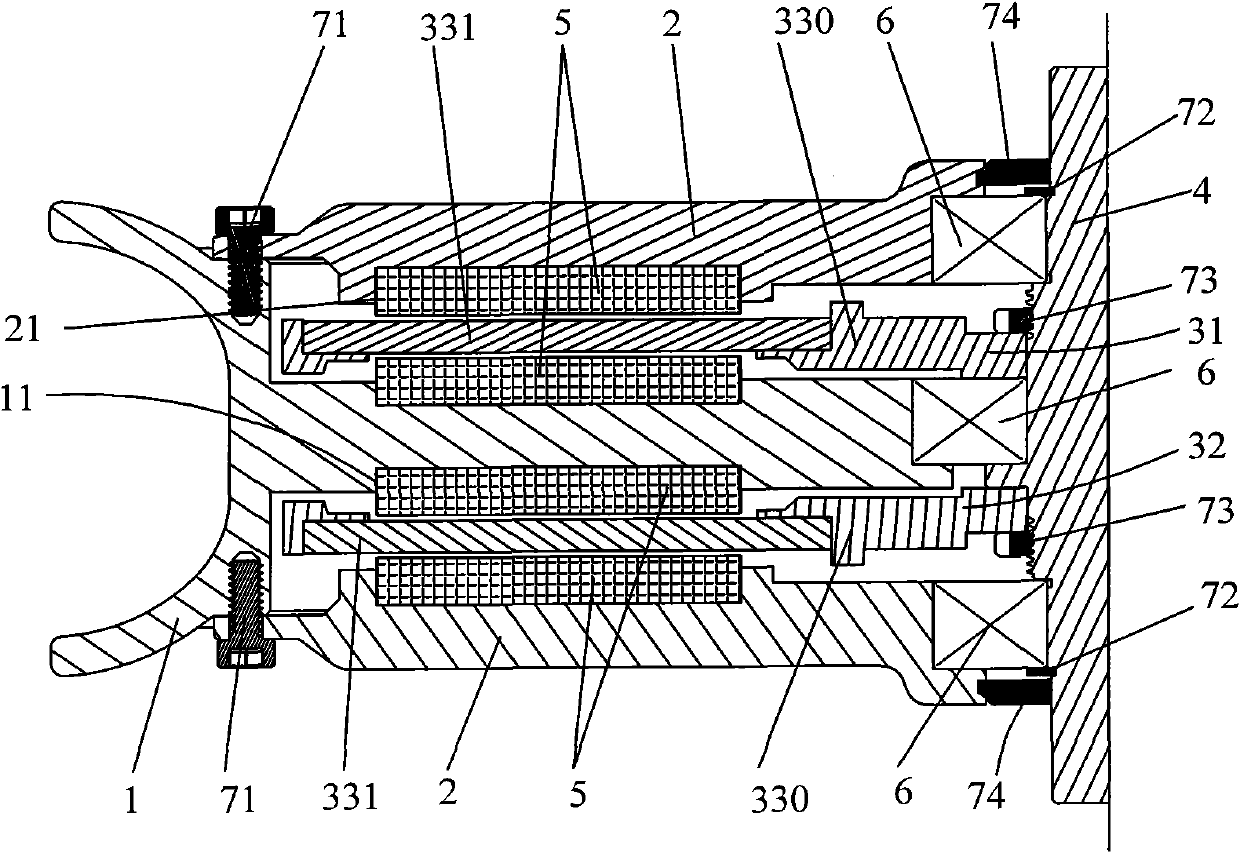

[0021] See figure 1 and figure 2 . The hub motor of the present invention includes a hub main body 1 , a rotor disk 2 , a stator 3 and a fixed shaft 4 . The hub main body 1 , the rotor disc 2 and the stator 3 are all of a centrally symmetrical structure, and the fixed shaft 4 is connected to the centers of the hub main body 1 , the rotor disc 2 and the stator 3 . in,

[0022] The hub main body 1 is made of a magnetically conductive metal material, which can be iron, steel, powder alloy, etc., and its external dimensions are determined according to the application occasion and power. Both sides of the hub main body 1 are provided with a first groove 11 for accommodating and fixing a permanent magnet. The first groove 11 is fan-shaped or annular, and its shape corresponds to the shape of the permanent magnet. A permanent magnet 5 is fixed in the first groove 11, and the permanent magnet 5 may be processed from rare earth permanent magnet materials such as NdFeB. Since the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com