Extrusion apparatus for the production of plastic pipes, and flexible seal for said device

A technology of extrusion molding and plastic pipes, which is applied in the direction of pipes/pipe joints/fittings, pipes, mechanical equipment, etc., can solve problems such as leaks, and achieve the effect of simple structure and full maintenance of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The illustrations in the drawings are not to actual size. Identical or identically acting elements are identified with the same reference symbols.

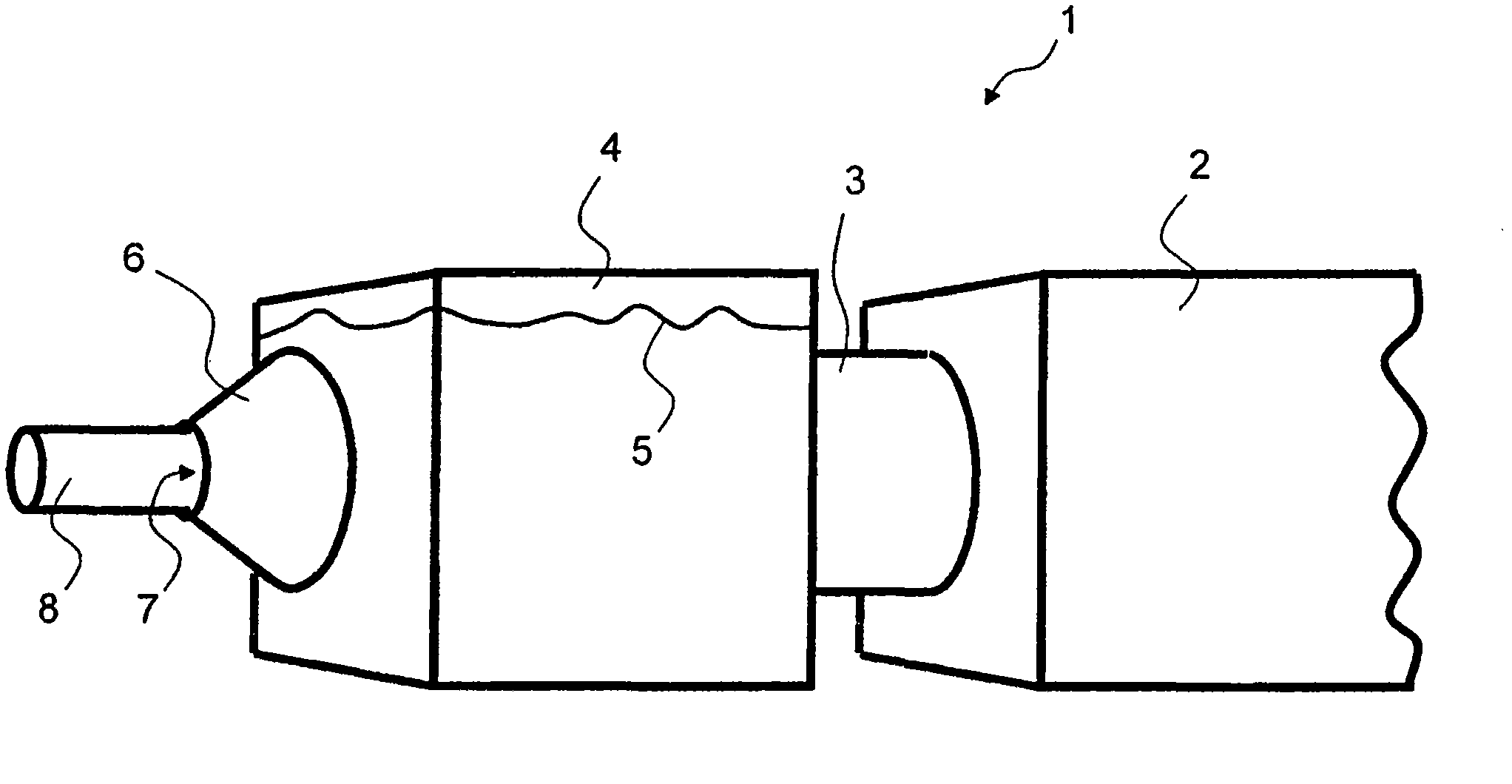

[0028] exist figure 1 shows an extrusion molding device 1 for producing so-called continuous profiles, wherein the continuous profiles are in particular plastic pipes. The extrusion device comprises in turn (not shown) a melting device for providing the deformable raw material, a (not shown) sizing device for defining the shape of the continuous profile, in particular the diameter of the plastic pipe.

[0029] After the plastic pipe has been produced in this way as a continuous profile, it is still in a state where it can be easily deformed and any external influences can change the outer dimensions of the plastic profile. In particular, plastic pipes that are still softened may collapse under atmospheric pressure. Thus, the semi-finished product is stabilized in the vacuum tank 2 in which the plastic tube hardens under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com