Electrostatic screen for an hvdct component

A high-voltage direct current, electrostatic shielding technology, applied in the direction of magnetic/electric field shielding, transformer/inductor parts, shielding materials, etc., can solve problems such as high cost and complicated use, achieve good contact, achieve matching, and reduce discharge time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

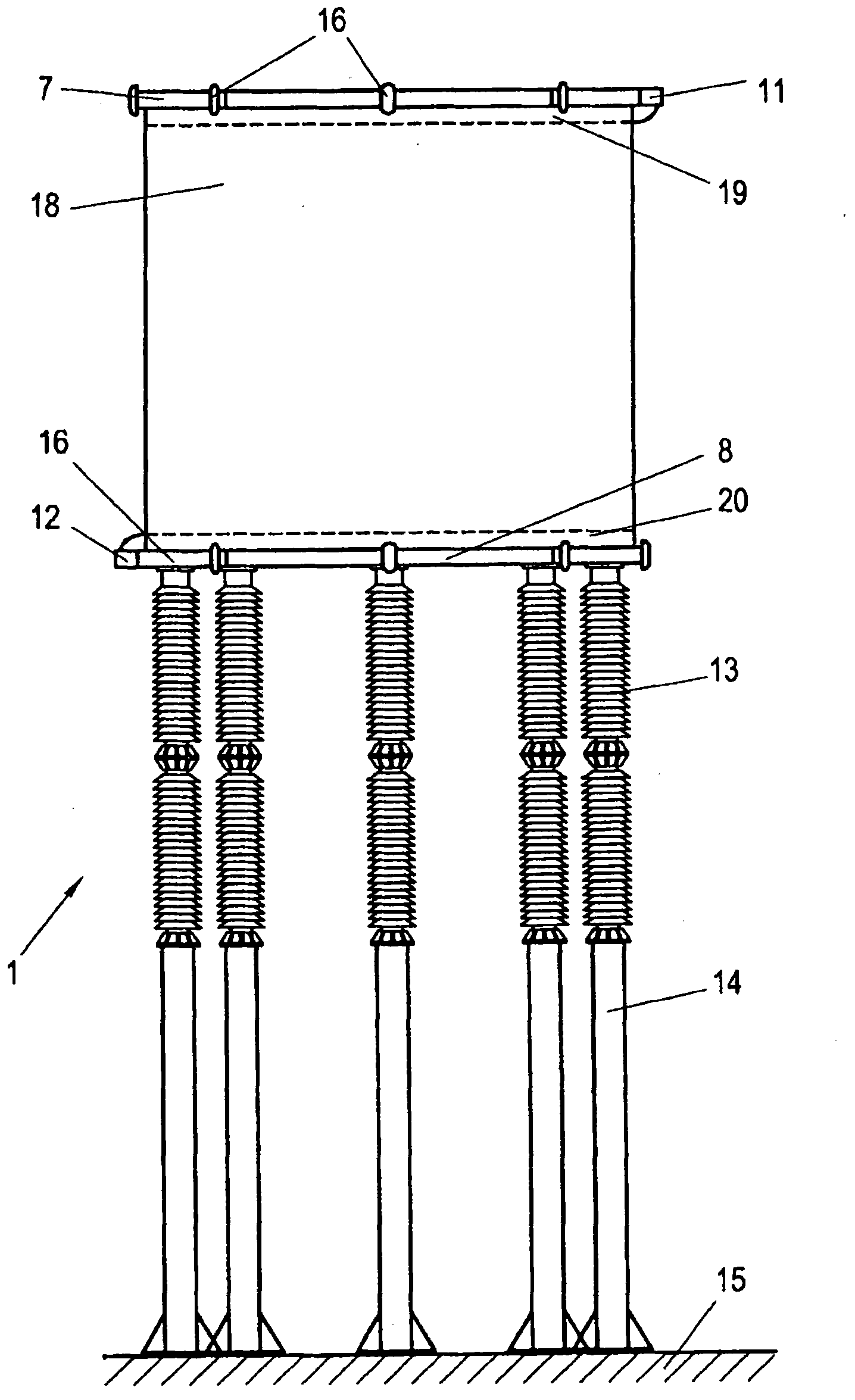

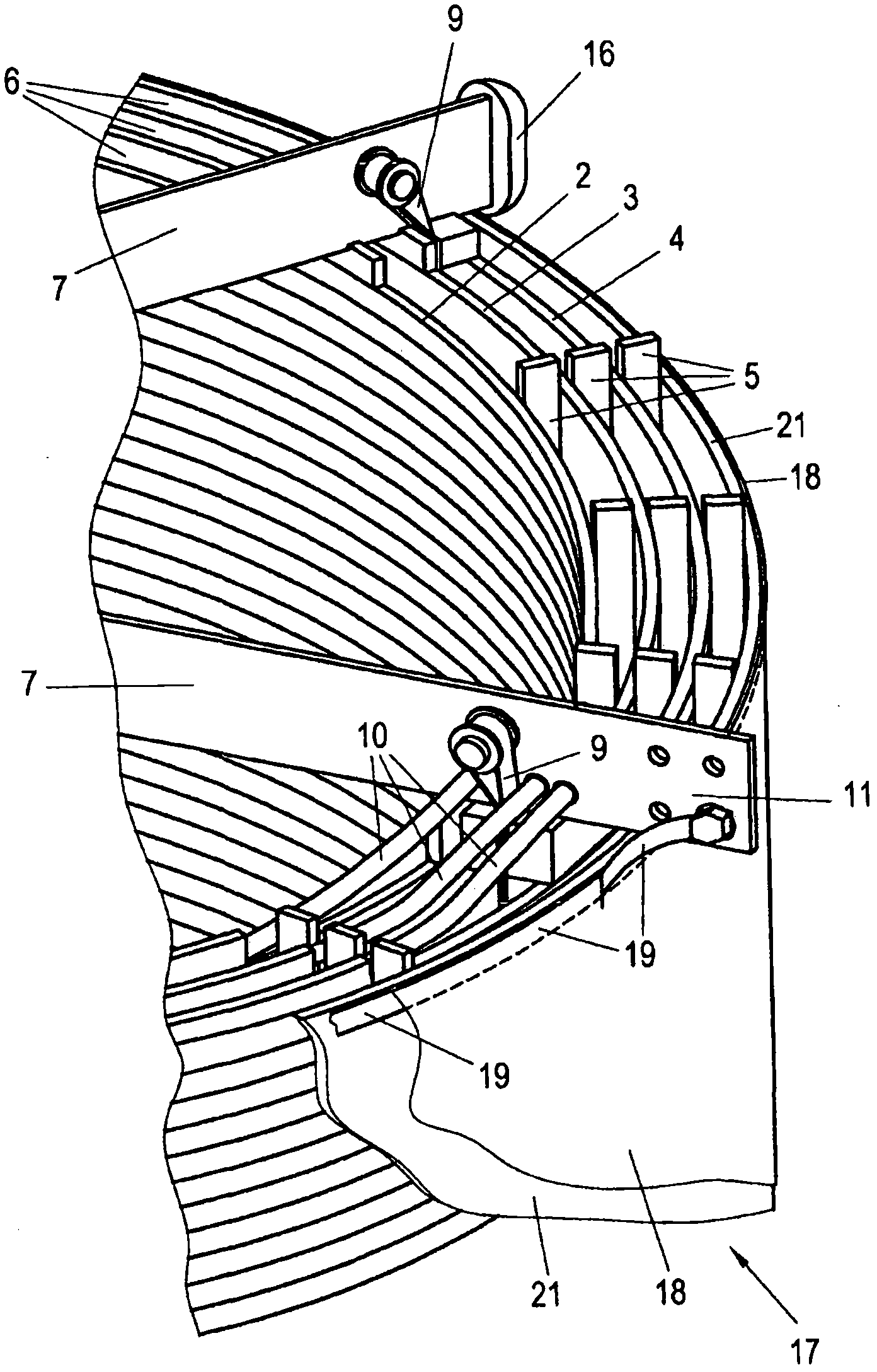

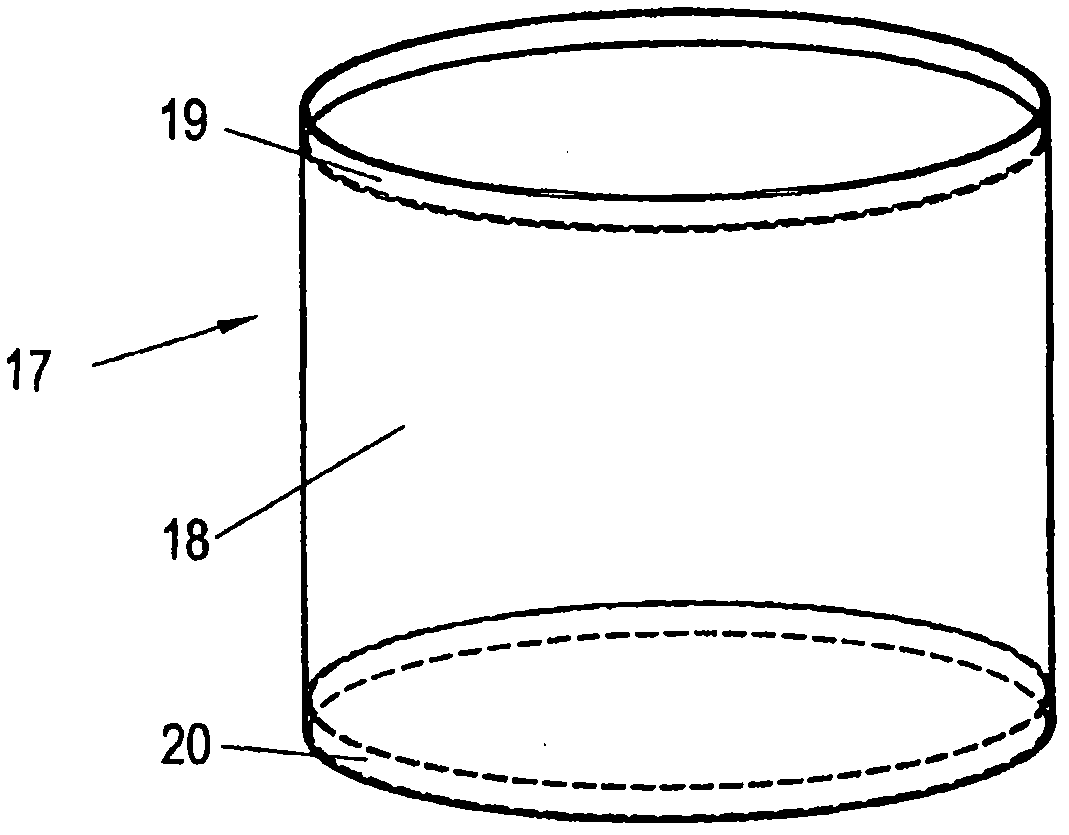

[0021] exist figure 1 with figure 2 shows a high-voltage direct current transmission air-core coil 1, which is for example in a high-voltage direct current transmission line is used as a filter choke.

[0022] Air core coils are "dry insulated" chokes, as opposed to oil insulated coils, where ambient air forms the external insulation of the choke, and air core coils generally also do not contain a ferromagnetic core.

[0023] In the example shown, the air-core coil 1 has three concentric, electrically parallel winding layers 2 , 3 , 4 which are spaced apart from one another by spacers 5 in order to form cooling gaps 6 between them.

[0024] The winding layers 2 to 4 are fixed at their upper and lower ends by a collection of multi-arm star supports 7 , 8 which are braced against one another by means of tension straps 9 . The conductors of the winding layers 2 to 4 are electrically connected to the star carrier 7 , 8 and the star carrier has lugs which form the connections ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com