Rape huller

The technology of a shelling machine and rapeseed is applied in the field of mechanical devices, which can solve the problems of labor-intensive, time-consuming and wasteful, and achieve the effect of reducing resource consumption and economical expenses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

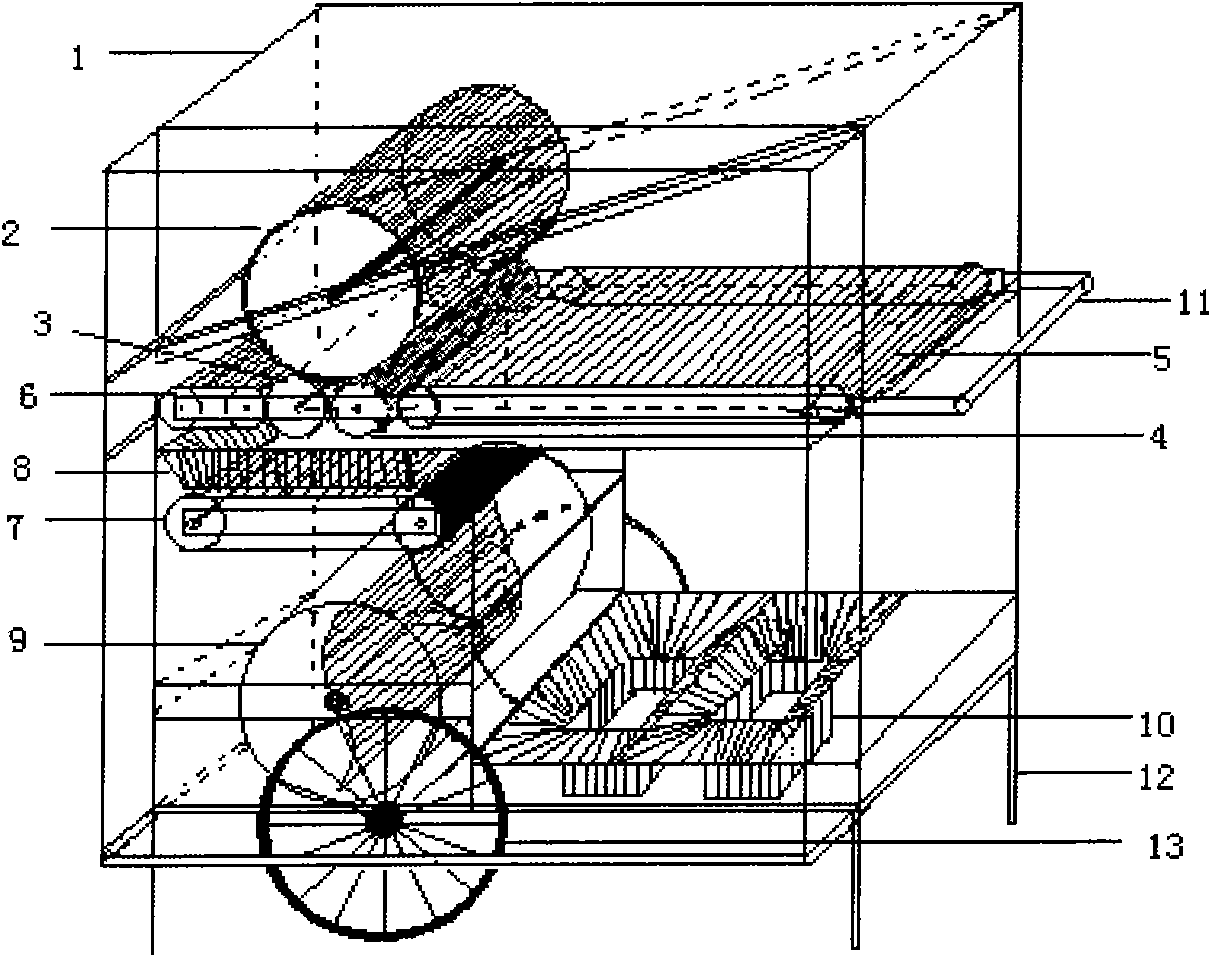

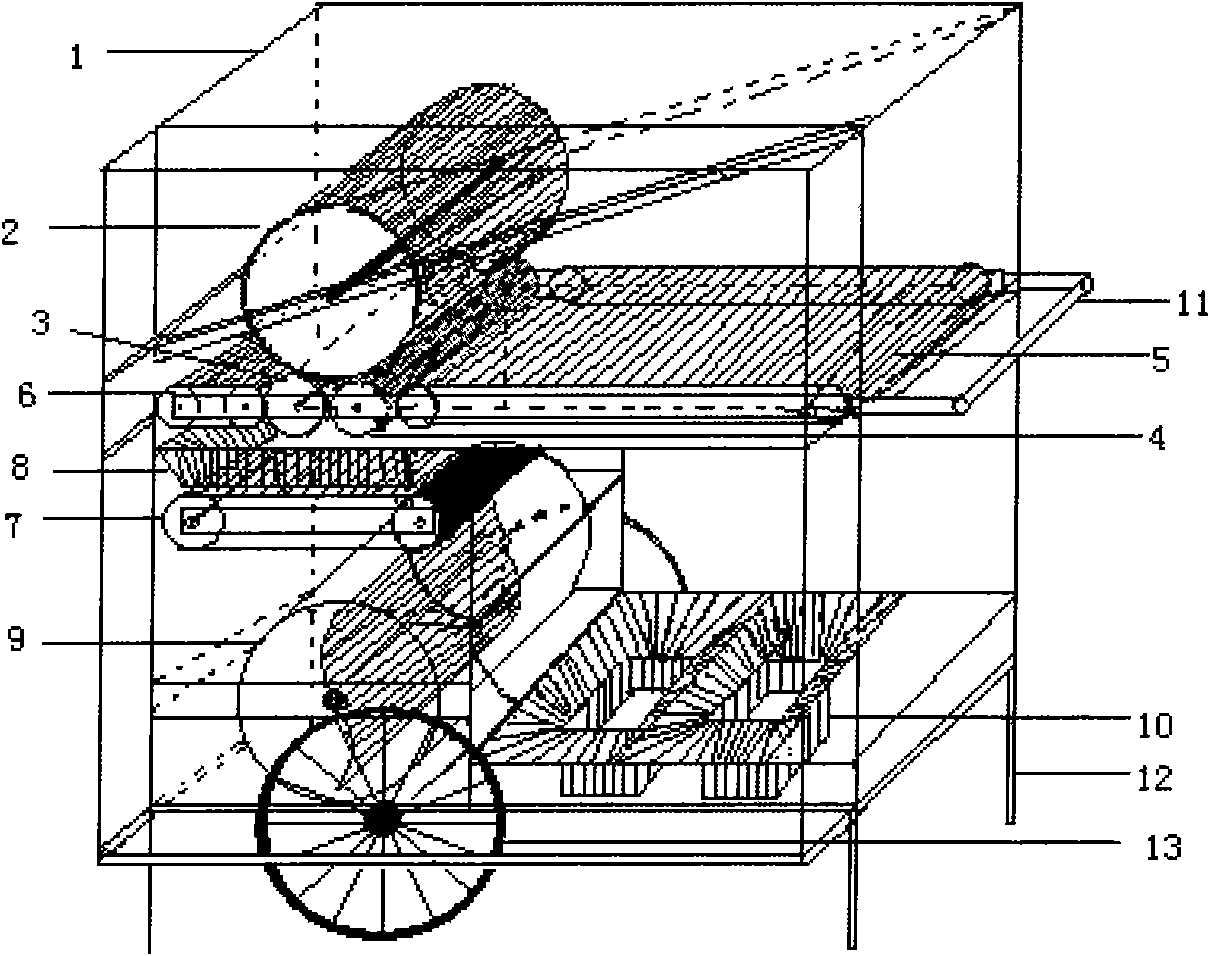

[0021] See attached picture.

[0022] The rape shelling machine includes a frame 1, a large roller 2 is mounted on the upper part of the frame 1 and left and right small rollers 3 and 4 are arranged side by side on the lower side of the large roller 2, and the large roller 2 is an inflatable rubber roller. State left and right small rollers 3,4 to be solid rubber rollers. The annular outer walls of the large roller 2 and the left and right small rollers 3 and 4 are respectively provided with strip grooves; there is a gap between the left and right small rollers 3 and 4; The input conveyor belt 5 of the transmission, the outside of the left roller 3 is provided with the output conveyor belt 6 that can be circulated, and the output conveyor belt 6 has dense leakage holes; the conveying direction of the input conveyor belt 5 and the output conveyor belt 6 is the same. The left and right small rollers 3, 4 and the lower side of the output conveyor belt 6 are provided with a colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com