Continuous punching and nut riveting device for automobile door lock catch

A technology of automobile door locks and nuts, which is applied in the field of automobile manufacturing, can solve the problems of high labor intensity, splash, smoke and dust, human health and environmental protection hazards, etc., to reduce labor intensity of workers, accurate positioning of material belt guide, stable quality and environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

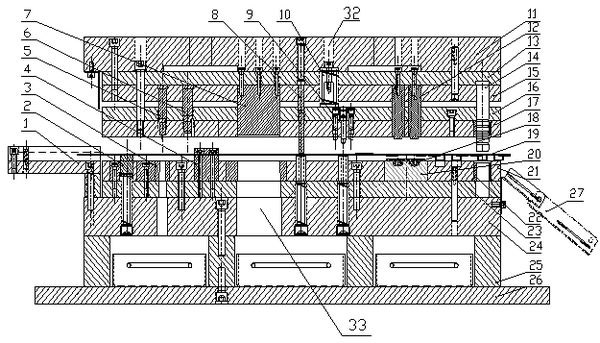

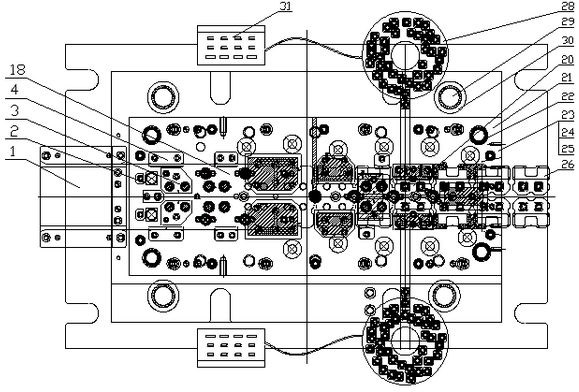

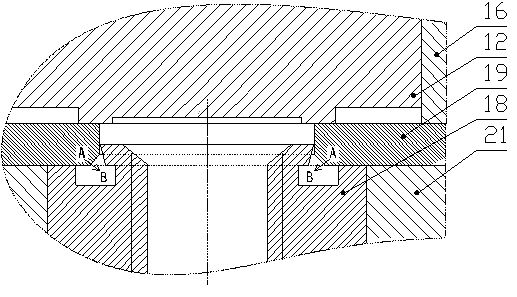

[0021] Such as figure 1 , figure 2 , Figure 5 As shown, the lower supporting plate 26 is installed on the workbench of the press, and the lower die base 24 is connected with the feet 25 and the lower supporting plate 26 with bolts and positioned with pins to fix the punching die 3 and the riveting die of the lower die assembly. 20. The die fixing frame 21 of the floating block 2, the material guide block 4, and the inner guide sleeve 22 is connected to the lower mold base 24 through the lower backing plate 22 with bolts and positioned with pins, and the floating block 2 lifts the material belt 19 The material guide block 4 plays the role of guiding the material belt 19, the inner guide sleeve 22 and the inner guide post 14 cooperate to guide the gap between the punch and the die, the riveting die 20 is embedded in the die fixing plate 21, and the guide Material rack 1 is contained on the lower mold base 24 and connects the circular pin positioning with bolts, and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com