Method for determining blade structure of mixing drum of concrete transit mixer

A technology of a mixer truck and blade structure, which is applied to cement mixing devices, chemical instruments and methods, clay preparation devices, etc., can solve the problem that the overall mixing performance of the concrete mixer truck cannot be greatly improved, and the mixing performance of the concrete mixer truck It can not be significantly improved, affecting the performance of the concrete mixer truck, so as to improve the mixing performance and discharge performance, ensure the flow field, and improve the smoothness of the blades.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation of the present invention will be further described below by taking the method for determining the mixing drum blade of a concrete mixer truck as an example.

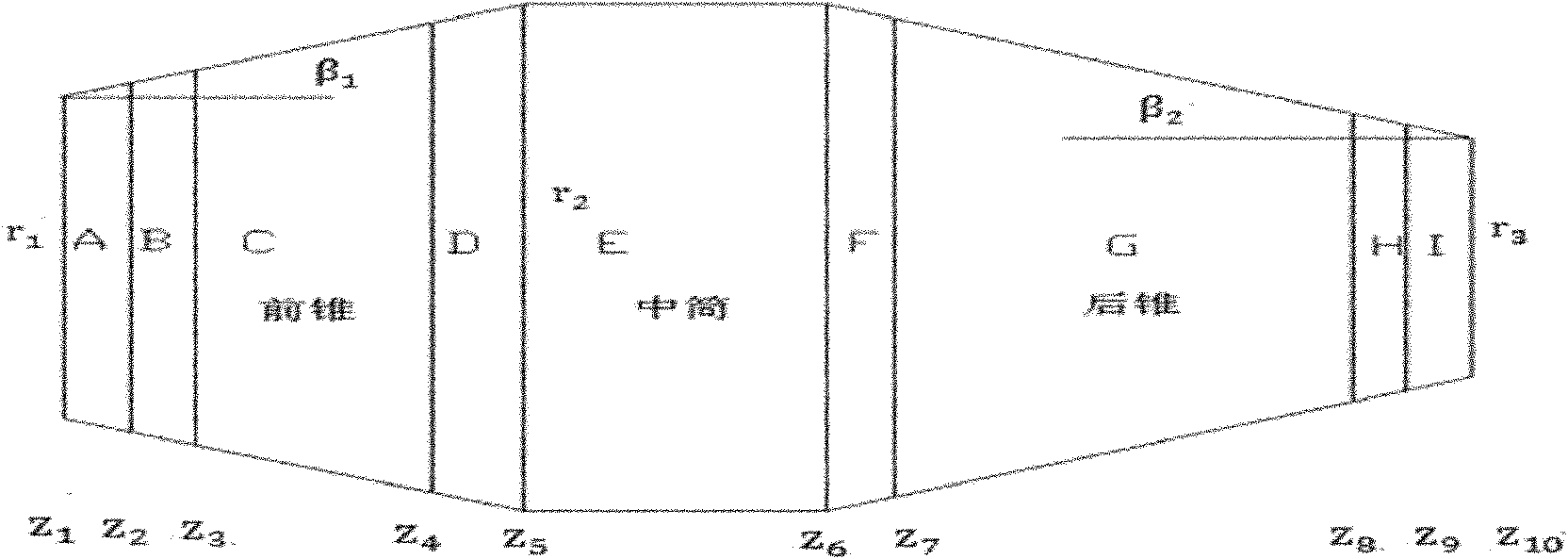

[0034] The parameters of the mixing drum blades are shown in Table 1, 2; where, r 1 is the tip radius of the front cone, r 2 is the radius of the middle cylinder, r 3 is the radius of the cone top; z 1 ~z 10 The numerical value of represents the height of each small part of the cylinder in the axial direction.

[0035] Follow the steps below to optimize the design:

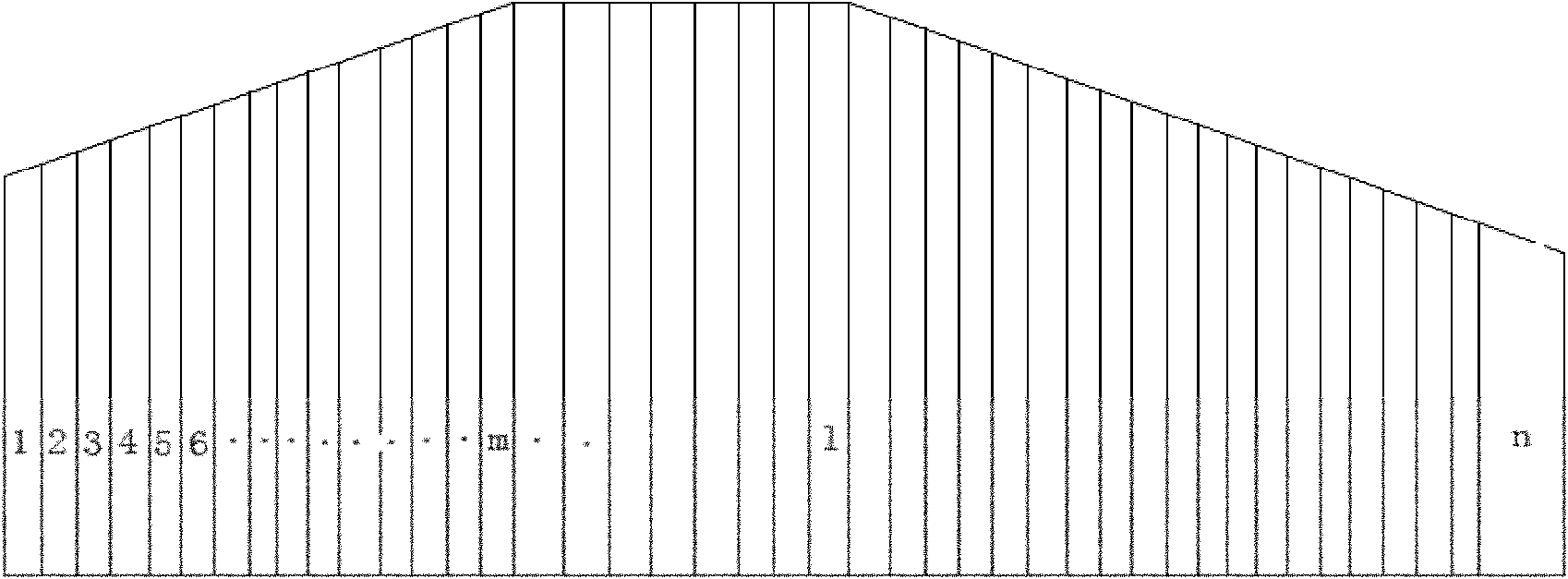

[0036] 1. If figure 2 As shown, the entire conical surface of the mixing drum of the concrete mixer truck is divided into 9 sections A-I, and A is defined as the end face area of the small mouth of the front cone, B is the helical line transition, C is the main mixing area, and D is the helical line transition area. E is the middle barrel, F is the helix transition zone, G is the stirring zone, H is the helix trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com