Integral hydraulic jacking inverted construction method of large converter

A construction method and technology of large-scale converters, applied in the direction of manufacturing converters, etc., can solve the problems of difficult installation precision control, inability to work in welding, and narrow installation sites, and achieve the effects of shortening the installation period, reducing construction costs, and facilitating construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0017] A large-scale converter overall hydraulic jacking upside-down construction method:

[0018] 1) Construction preparation

[0019] 1) Weld the furnace shell to form a whole.

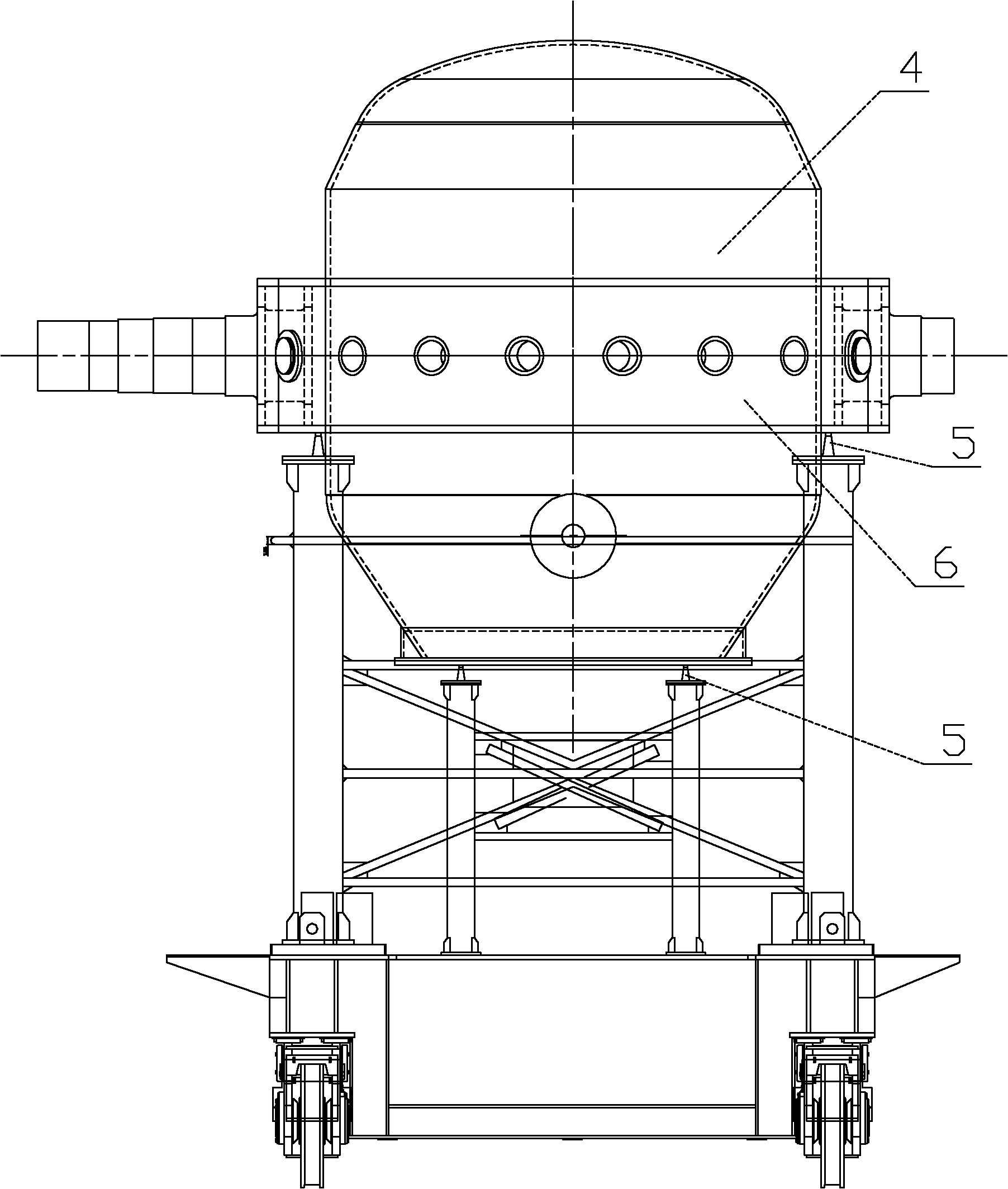

[0020] 2) Make the furnace shell support for supporting the furnace shell and the integral support for supporting the furnace shell and the supporting ring.

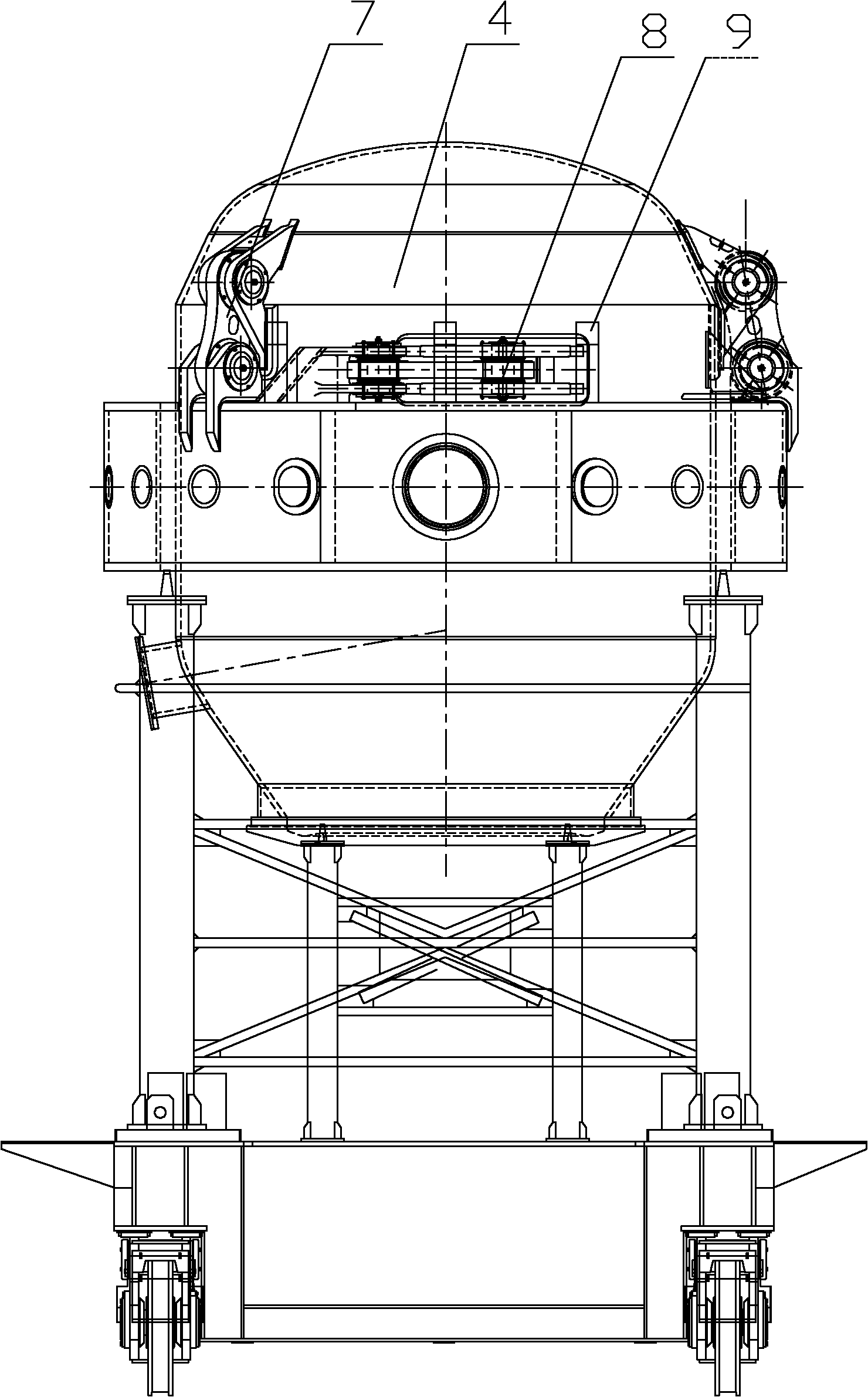

[0021] 3) Make a dummy shaft for hanging assembly; make a positioning block between the inner side of the hanging lug seat and the hanging connecting rod.

[0022] 4) Make the furnace shell limit block.

[0023] 5) Arrange the reverse chain on the other side of the converter foundation for the forward power of the molten steel tanker.

[0024] 2) Construction steps:

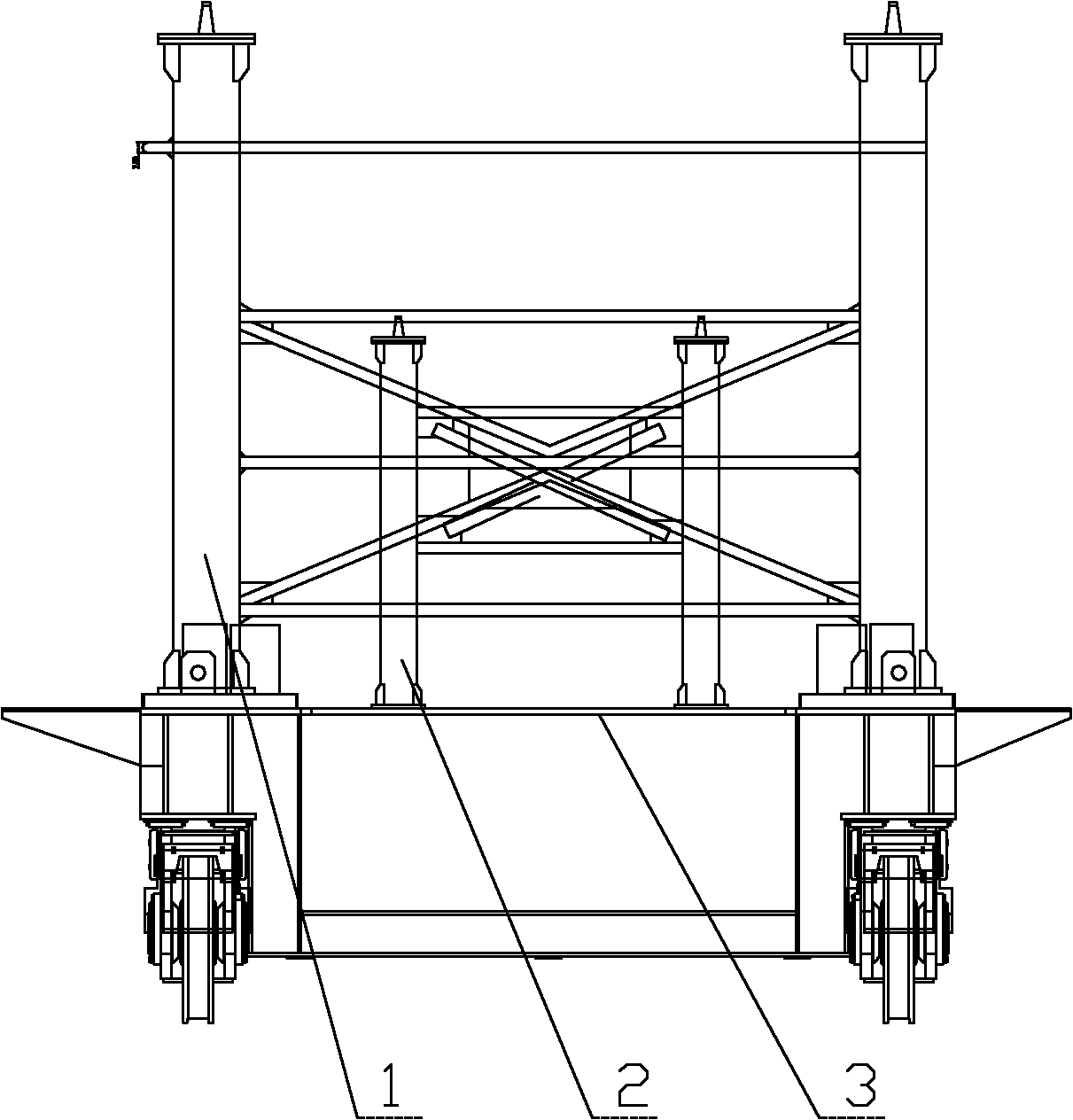

[0025] 1) See figure 1 , at the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com