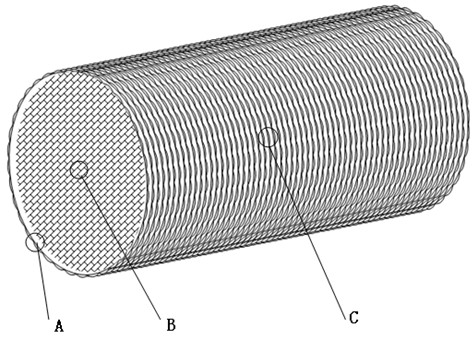

Machine woven artificial trachea

A technology of artificial trachea and outer tube, which is applied to devices with tubular structures of the human body, fabrics, textiles, etc., can solve the problems of difficult control and cumbersome fixing of elastic materials, and achieve the difficulty of simplifying operation, simplifying the difficulty of design and operation, and ensuring diameter effect on support performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

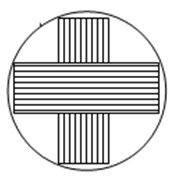

[0025] Taking the double-layer tissue as an example, the weaving method of this kind of artificial trachea structure is introduced. The artificial trachea is made of 90D / 36f polyester multifilament and polypropylene monofilament with a diameter of 0.18mm; the weave is 2 / 1 right twill weave on the surface, 1 / 2 right twill weave on the inner weave, and the outer warp and the inner warp are knotted Alternately used double layers of tissue. The warp and weft yarns of the surface layer are made of polypropylene monofilament, and the warp and weft yarns of the inner layer are made of polyester multifilament. Surface longitude: surface latitude = 1:2, interior longitude: interior latitude = 1:2. The weaving parameters are shown in Table 1. After weaving, its organizational diagram is as follows image 3 shown.

[0026] Table 1 Weaving parameters

[0027] Warp density * weft density (root / 10cm)

Embodiment 2

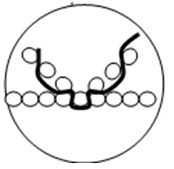

[0029] Taking Wei Erzhong as an example, the weaving method of this kind of artificial trachea structure is introduced. The material of the artificial trachea is the same as in Example 1; the weave double weave formed by the surface weave 1 / 5 right twill and the back weave 2 / 1 right twill is used. The warp is made of polyester multifilament; the surface weft is made of polypropylene monofilament, and the inner weft is made of polyester multifilament. Table weft: inner weft = 1:1. The weaving parameters are shown in Table 2. After weaving, its organizational diagram is as follows Figure 4 shown.

[0030] Table 2 Weaving parameters

[0031] Warp density * weft density (root / 10cm)

[0032] Number of reeds (in / reed)

Embodiment 3

[0034] Taking Wei Erzhong as an example, the weaving method of this kind of artificial trachea structure is introduced. The artificial trachea is made of 180D PLA multifilament and PDS monofilament with a diameter of 0.23mm; the weave is double weft formed by the surface weave of 1 / 7 right twill and the inner weave of 3 / 1 right twill. The warp yarn is made of PLA multifilament; the surface weft yarn is made of PDS monofilament, and the inner weft yarn is made of PLA multifilament. Table weft: inner weft = 1:1. The weaving parameters are shown in Table 3 below. After weaving, its organizational diagram is as follows Figure 5 shown.

[0035] Table 3 Weaving parameters

[0036] Warp density * weft density (root / 10cm)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com