Ring-shaped lifting operating platform for vertical storage tank

A technology for operating platforms and vertical storage tanks, which is applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of high foundation, small foundation plane size, difficulties, etc. The effect of short time and quick construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] This embodiment is suitable for a vertical storage tank with a diameter of 8.5m.

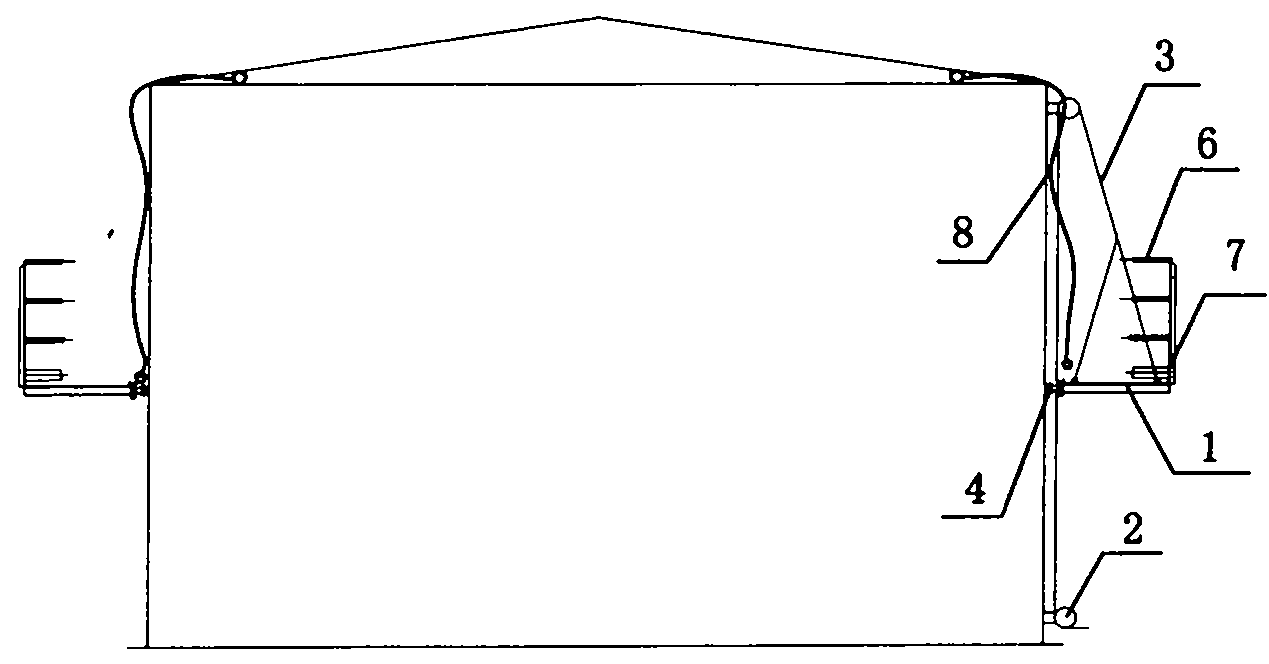

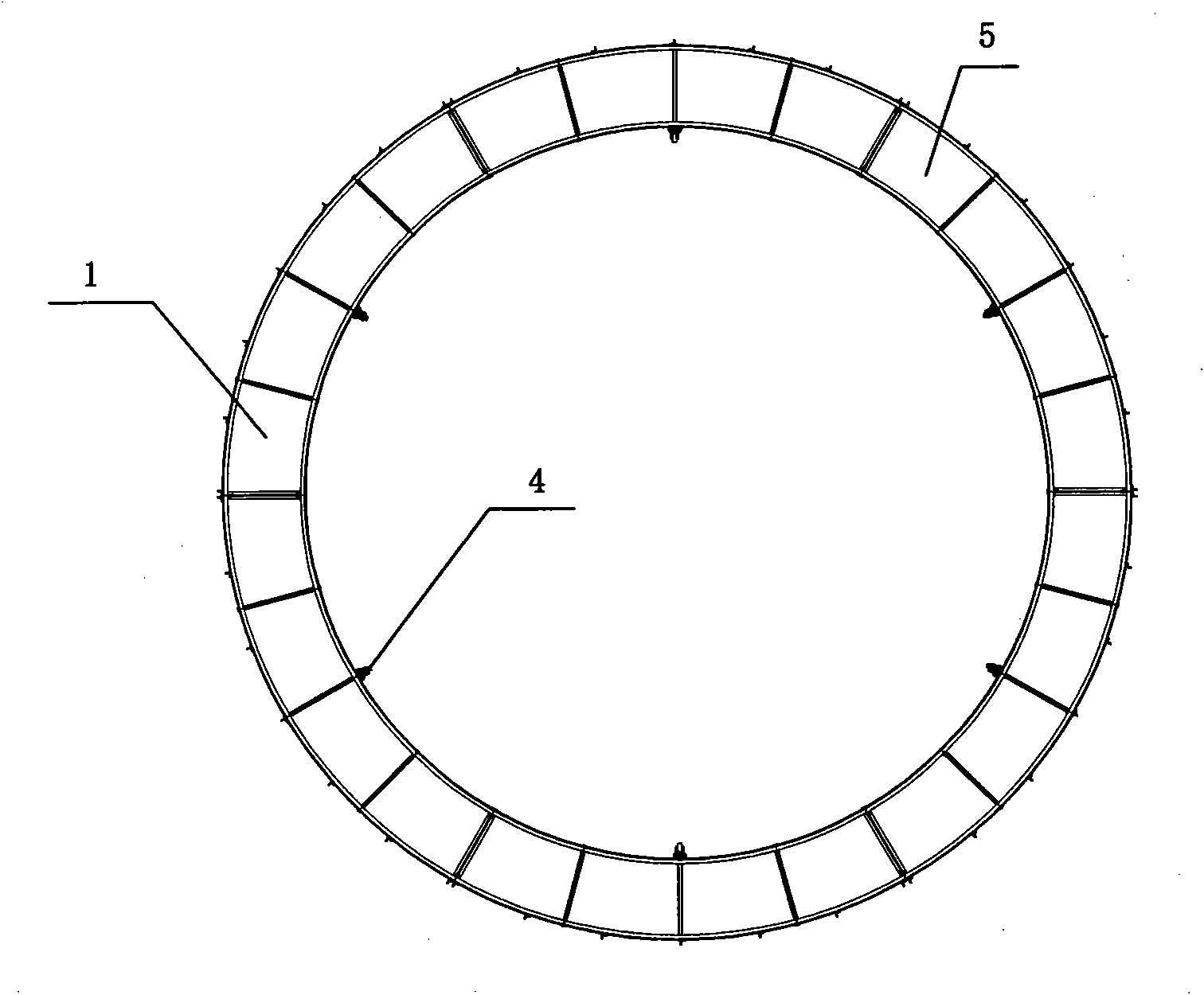

[0018] As shown in the figure, the ring-shaped lifting operation platform for vertical storage tanks in this embodiment includes a horizontal ring-shaped operation platform 1, which is suspended on the vertical storage tank, and is respectively arranged on the top and base of the vertical storage tank. Corresponding fixed pulleys 2 are used to lift the fixed rope 3 and pass through the fixed pulleys 2 to connect with the horizontal circular operating platform 1. The inner side of the horizontal circular operating platform 1 is provided with a guide wheel 4 sliding along the outer wall of the vertical storage tank for horizontal circular operation. The platform 1 is surrounded by an annular flat plate 5, six sets of guide wheels 4 are arranged on the inside of the horizontal annular operating platform, six sets of fixed pulleys 2 are arranged on the vertical storage tank, and a horizontal p...

Embodiment 2

[0025] This embodiment is applicable to a vertical storage tank with a diameter of 10m.

[0026] The difference between this embodiment and Embodiment 1 is that the unfolded length of each ring-shaped plate 5 is 4.48m, eight sets of guide wheels 4 are arranged inside the horizontal ring-shaped operating platform, and eight sets of fixed pulleys 2 are arranged on the vertical storage tank.

Embodiment 3

[0028] This embodiment is suitable for a vertical storage tank with a diameter of 15m.

[0029] The difference between this embodiment and Embodiment 1 is that the unfolded length of each ring-shaped plate 5 is 5.15m, ten sets of guide wheels 4 are arranged inside the horizontal ring-shaped operating platform, and ten sets of fixed pulleys 2 are arranged on the vertical storage tank.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap