Method for predicting failure pressure of reservoir with acid damage

A fracture pressure and reservoir technology, applied in the field of oil and gas field development, can solve the problems of reducing the effect of reducing reservoir fracture pressure, casing damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

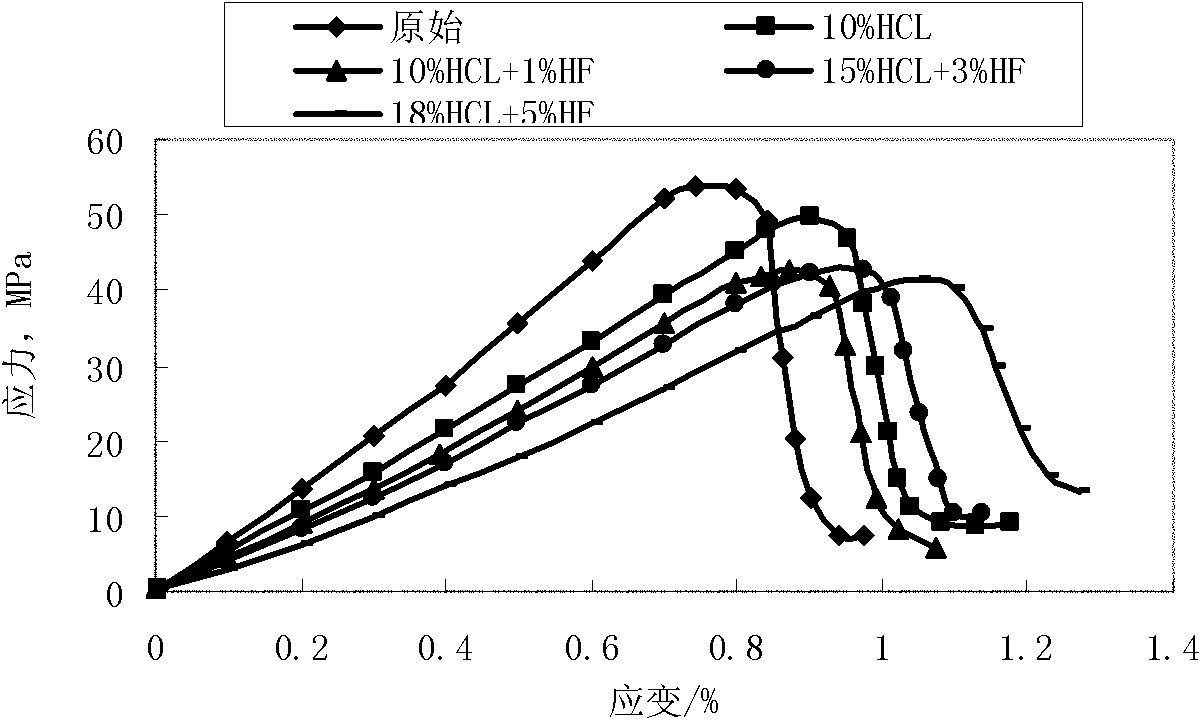

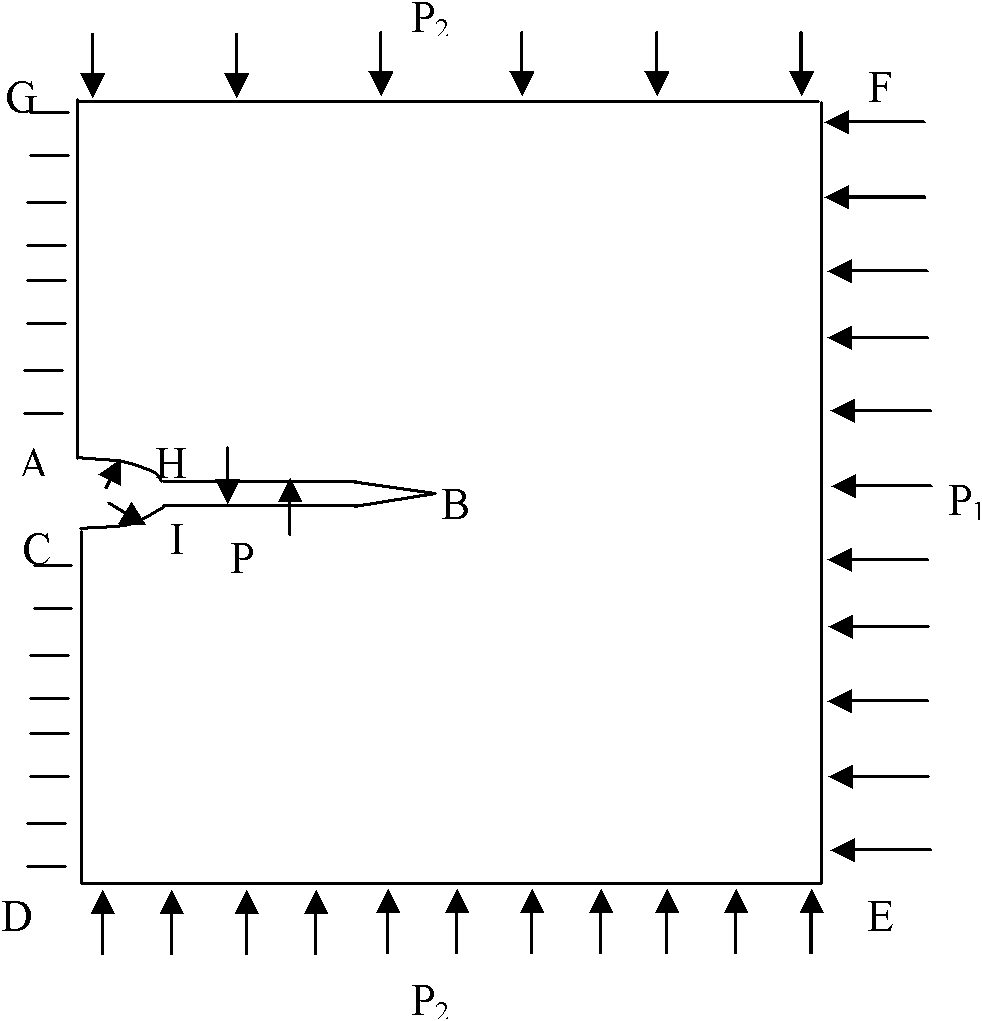

[0073] Further illustrate the present invention below in conjunction with accompanying drawing.

[0074] A method for predicting reservoir fracture pressure after acid damage mainly includes the following steps:

[0075] (1) Prepare a standard cylindrical rock sample that meets the experimental conditions:

[0076] A standard cylindrical sample of 25.4 mm × 50.0 mm is drilled in the reservoir rock pillar retrieved from the site with a diamond core drill bit, and then the two ends of the cylindrical sample are flattened and polished, and the cracks in the process;

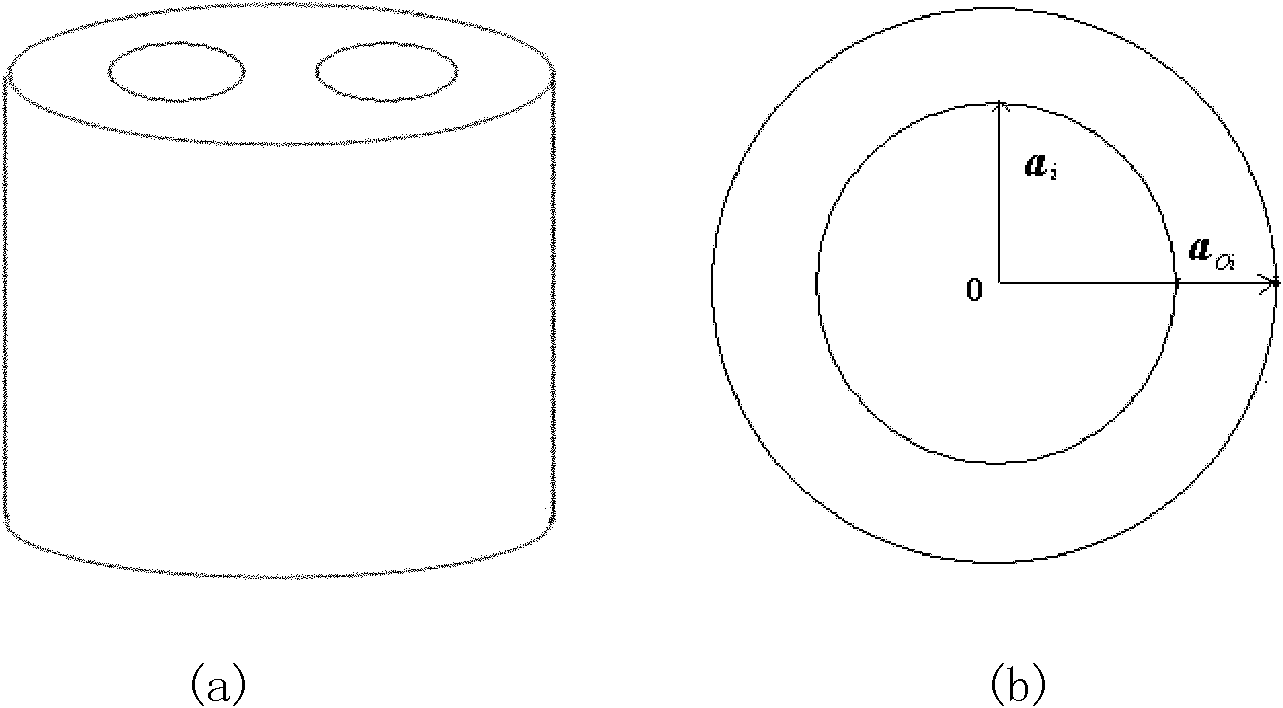

[0077] (2) A well-prepared rock sample cylinder is analyzed through the whole rock ore to obtain the single mineral type, composition and content of the reservoir rock, and the initial radius of the single mineral cylinder is calculated:

[0078] 1) Take a prepared rock sample cylinder, crush it with a jaw crusher to a particle size of 0.5-1.0mm, and take 10-20g by shrinkage method for later use. Epoxy resin is u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com