Self-aligning spherical plain water lubricated tail bearing for ships

A self-aligning, tail bearing technology, applied in sliding contact bearings, engine lubrication, bearing components, etc., can solve the problems of large coaxiality error, noise, and increased wear between the tail bearing and the tail shaft, and achieve uniform pressure distribution , the overall distribution is uniform, and the effect of pressure peak reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The content of the present invention will be further clarified below in conjunction with the embodiments and accompanying drawings, but the content of the present invention is not limited to the following embodiments.

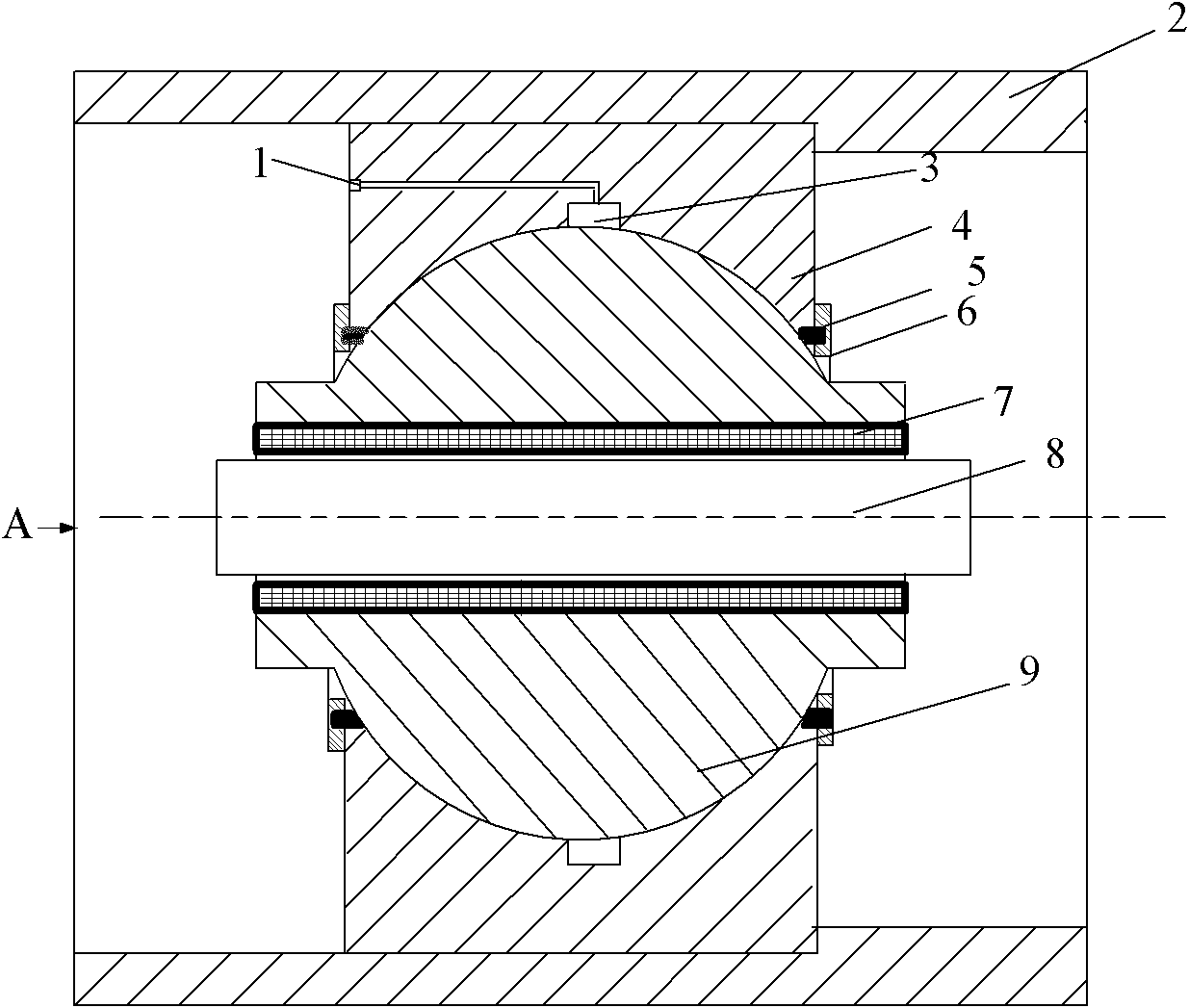

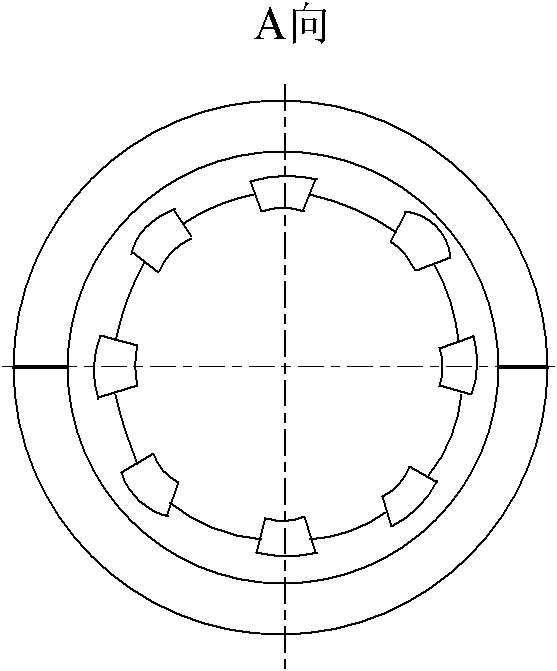

[0023] The marine self-aligning spherical sliding water-lubricated stern bearing (hereinafter referred to as the stern bearing) provided by the present invention has the structure as follows: figure 1 As shown, there are two pairs of friction pairs, one pair more than conventional sliding bearings, wherein: the inner ring 9 and the outer ring 4 are a pair, which are lubricated with grease. The inner ring 9 has a lining 7, and the lining 7 and the tail shaft 8 are a pair of friction pairs, which are lubricated by water.

[0024] The outer ring 4 is equipped with an oil injection mechanism 1 for adding grease. The outer ring can be made of tin bronze (ZQSn10-1), which has high hardness, good wear resistance, good corrosion resistance in the atmosphere an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com